YST desulphurization and decyanation, and salt extraction method of coke-oven gas

A coke oven gas, desulfurization and decyanation technology, applied in the direction of thiocyanate, thiosulfate/dithionite/polythionate, combustible gas purification, etc., can solve the problem of high catalyst price, long process flow, Big investment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

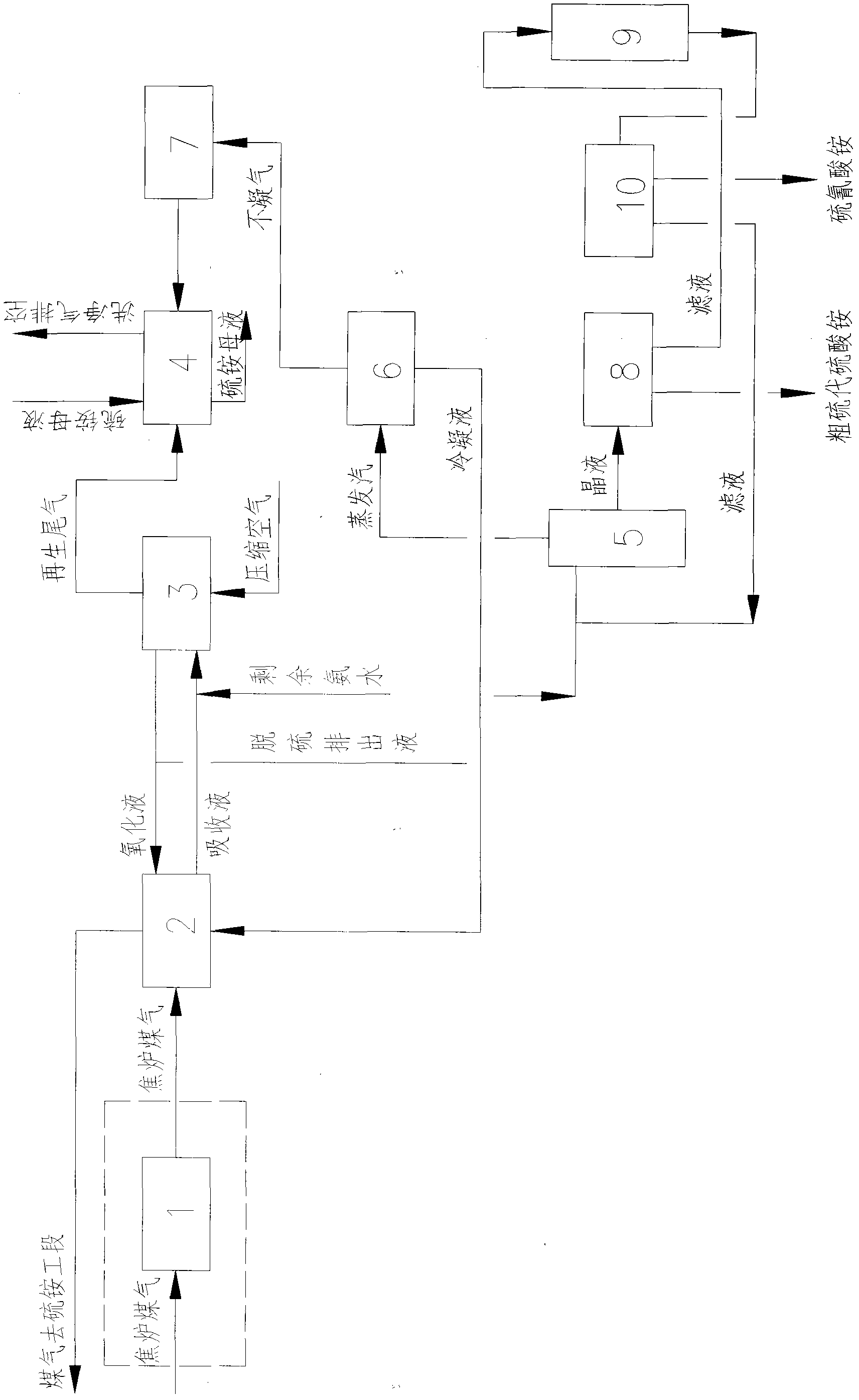

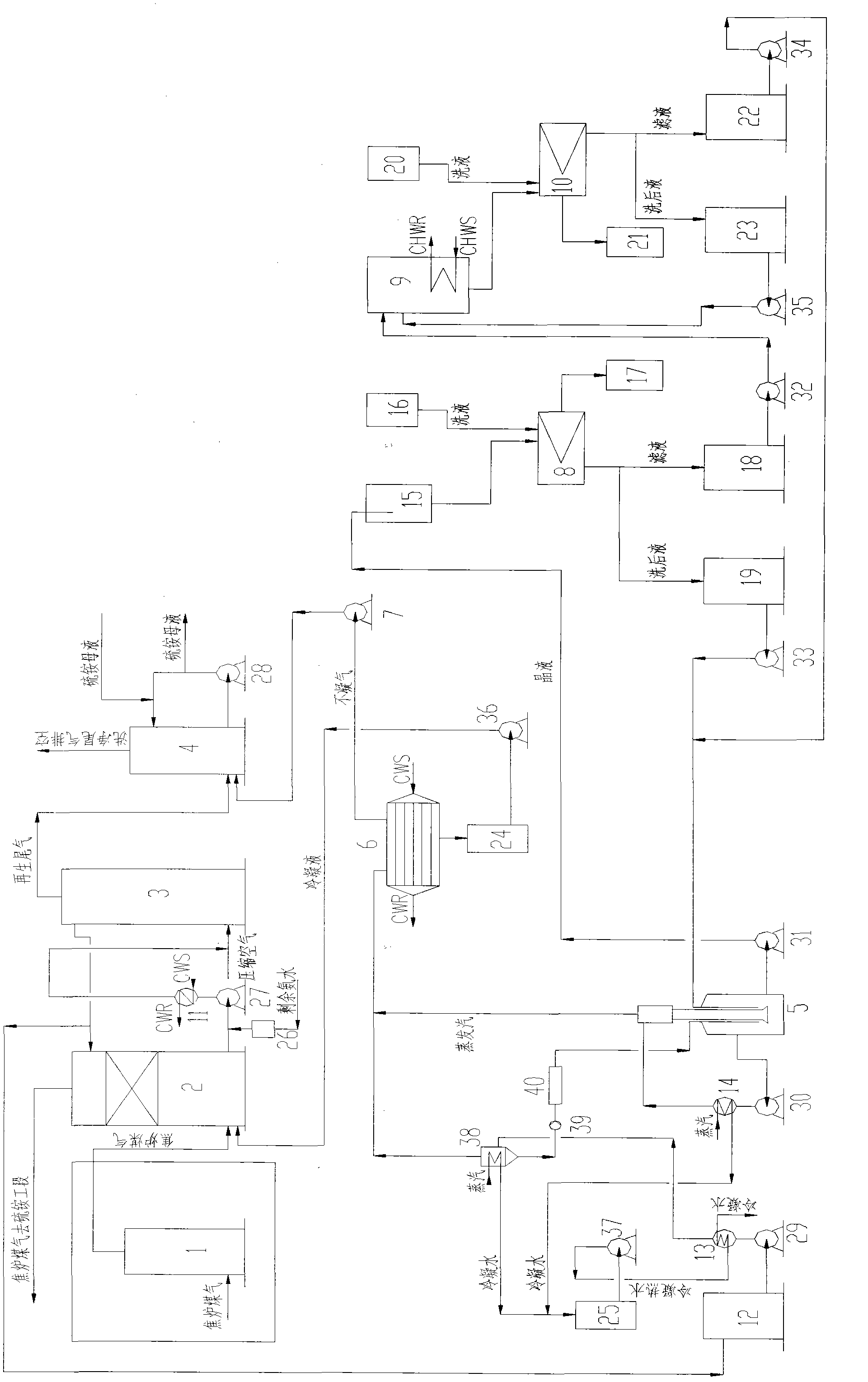

Method used

Image

Examples

Embodiment

[0050] At present, the world's first production device applying YST desulfurization, decyanation and salt extraction process has been successfully operated in Hangzhou Iron and Steel Coking Plant.

[0051]Hangzhou Iron and Steel Coking Plant had an improved ADA desulfurization unit. After long-term desulfurization, the content of hydrogen sulfide in the gas cannot meet the standard. In addition, the environment is seriously polluted during sulfur melting, the waste liquid is not easy to handle, and the production cost is high. It cannot meet the requirements of the society and Hangzhou Iron and Steel, and urgently needs to be upgraded. After investigating and researching various desulfurization and decyanation methods at home and abroad but not finding one that can meet the requirements of Hangzhou Iron and Steel, we can only find new methods. Under this premise, the inventor made innovations on the basis of summarizing the experience of the predecessors, and after the verific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com