Preparation method of copper-phosphorus alloy anode

A technology of alloy anodes and ingots, applied in the direction of electrodes, etc., can solve the problems of grain orientation, grain size that cannot meet the requirements of electroplating, and the metal film of integrated circuits is not uniform enough, so as to avoid cracks or other defects and improve the structure And mechanical properties, the effect of uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention mainly uses the method of combining plastic deformation with a specific deformation rate and heat treatment at a specific temperature for multiple times, and strictly controls the deformation rate of plastic deformation, the temperature and time of heat treatment to realize the production of grain orientation and grain size that meet the requirements of electroplating. Grain-sized copper-phosphorus alloy anodes.

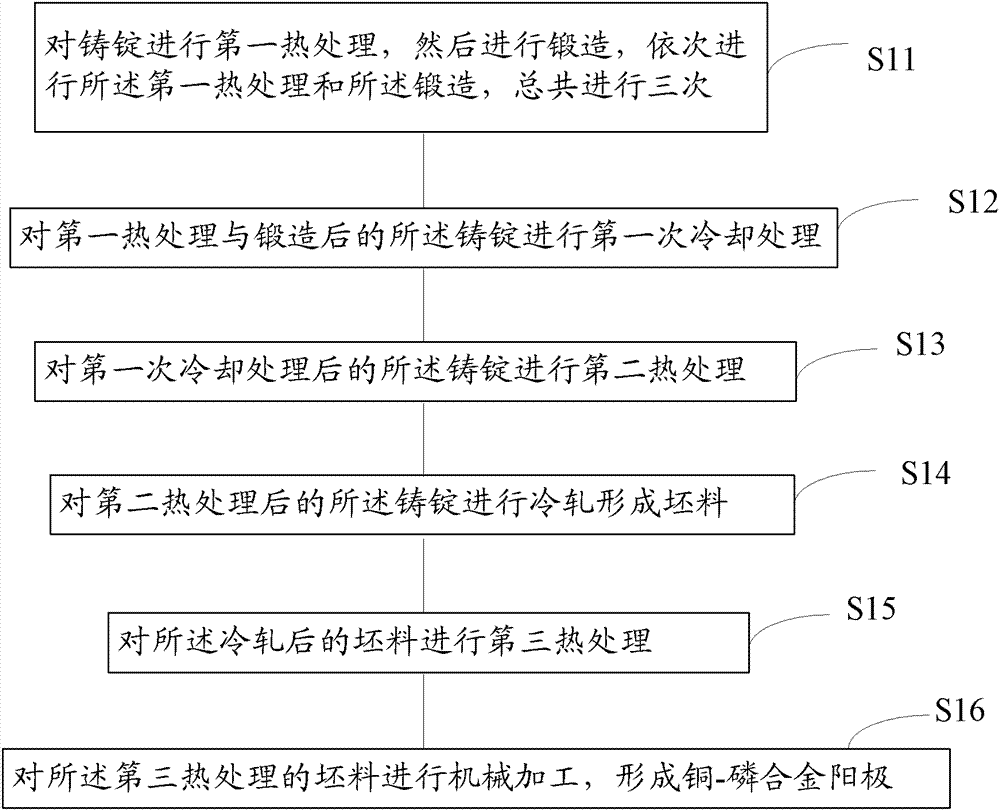

[0039] The inventor's dedicated research and repeated practice improvements have obtained the optimal method for making copper-phosphorus alloy anodes, the process flow of which is as follows figure 1 As shown, it mainly includes the following steps:

[0040] Step S11, performing the first heat treatment on the ingot, and then forging, performing the first heat treatment and the forging in sequence, a total of three times;

[0041] Step S12, performing a first cooling treatment on the ingot after the first heat treatment and forging;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com