Method for detecting plasticizer content in solid sample by headspace solid phase microextraction gas chromatography-tandem mass spectrometry

A technology of tandem mass spectrometry and gas chromatography, which is applied in the field of headspace solid-phase microextraction gas chromatography-tandem mass spectrometry in the detection of plasticizer content in solid samples, to achieve the effects of simple pretreatment, expanded range, and improved accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

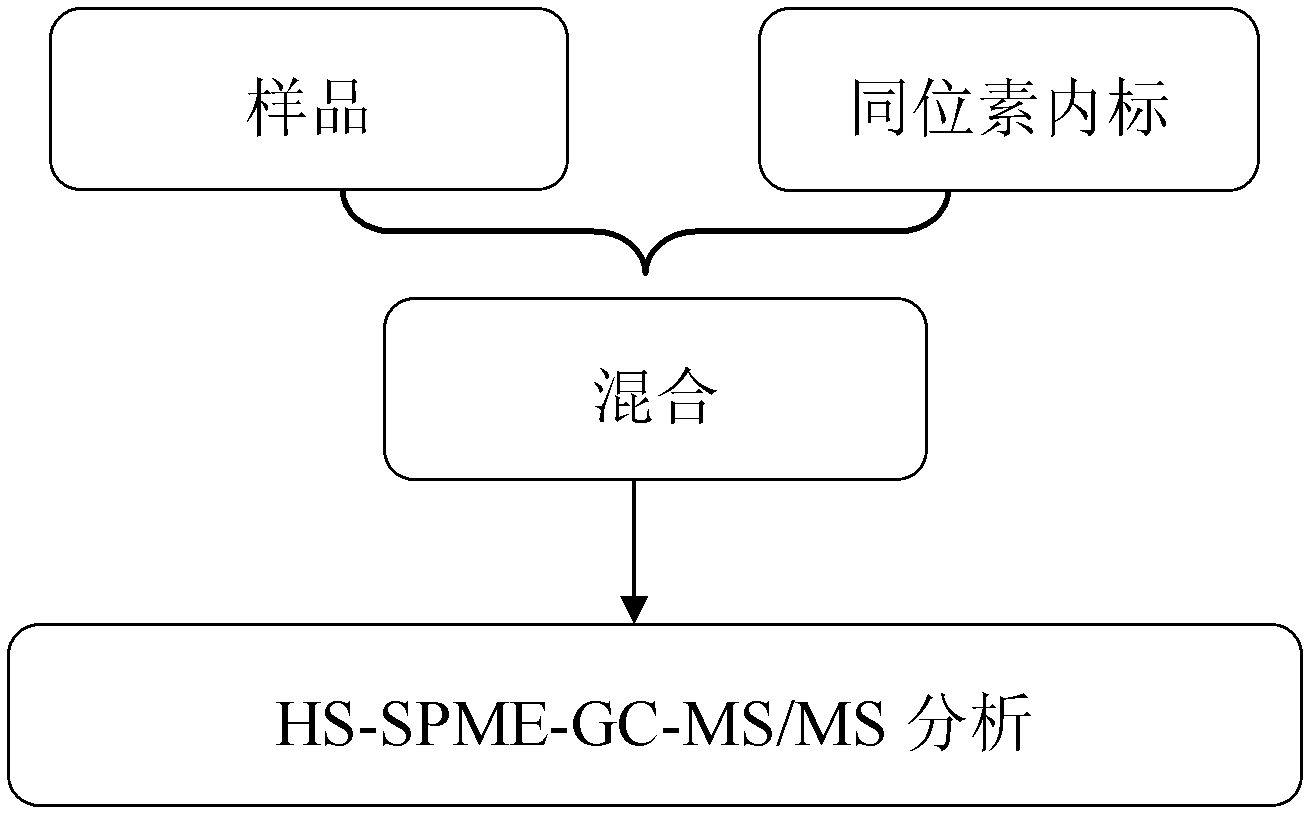

Method used

Image

Examples

Embodiment 1

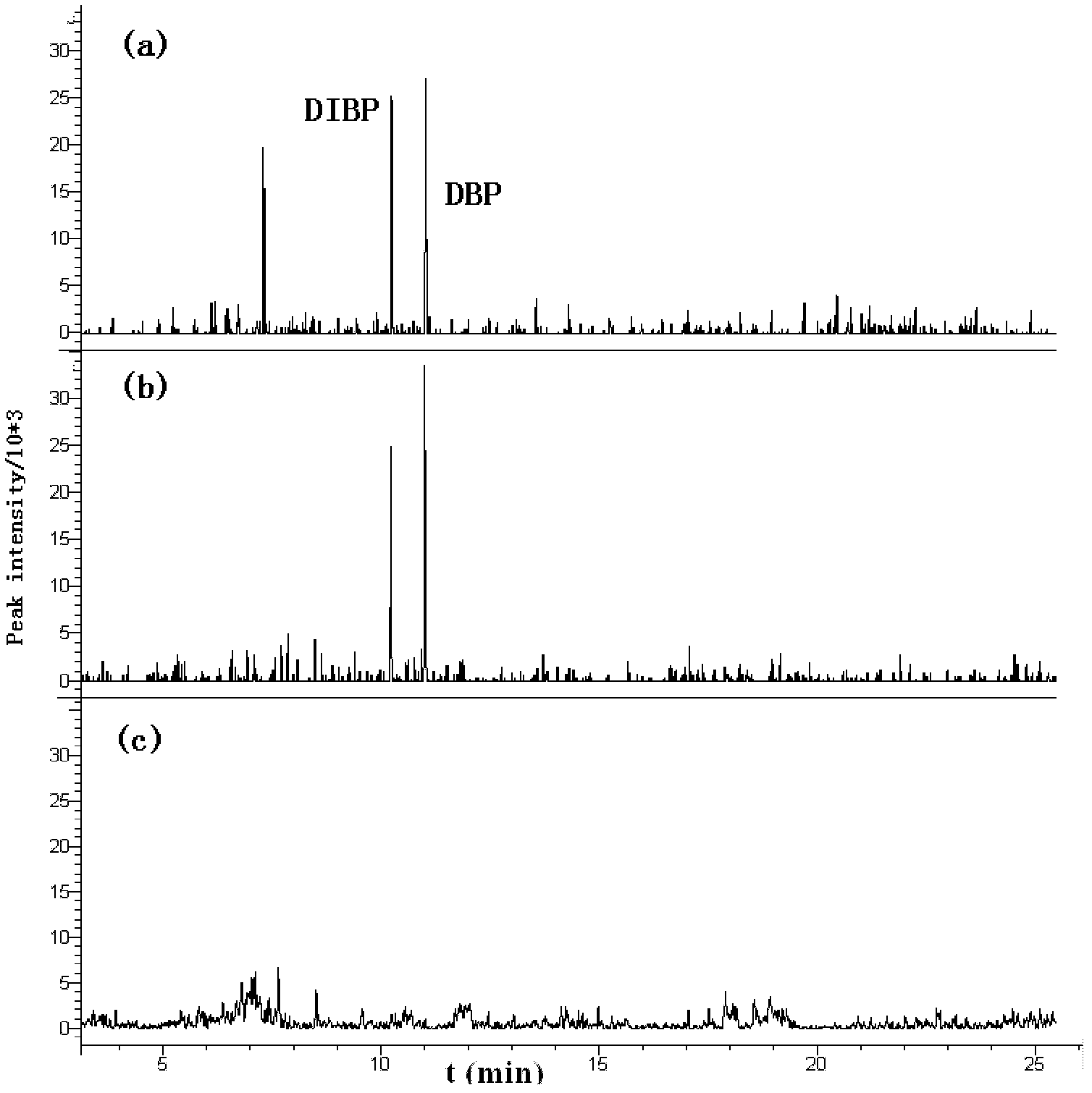

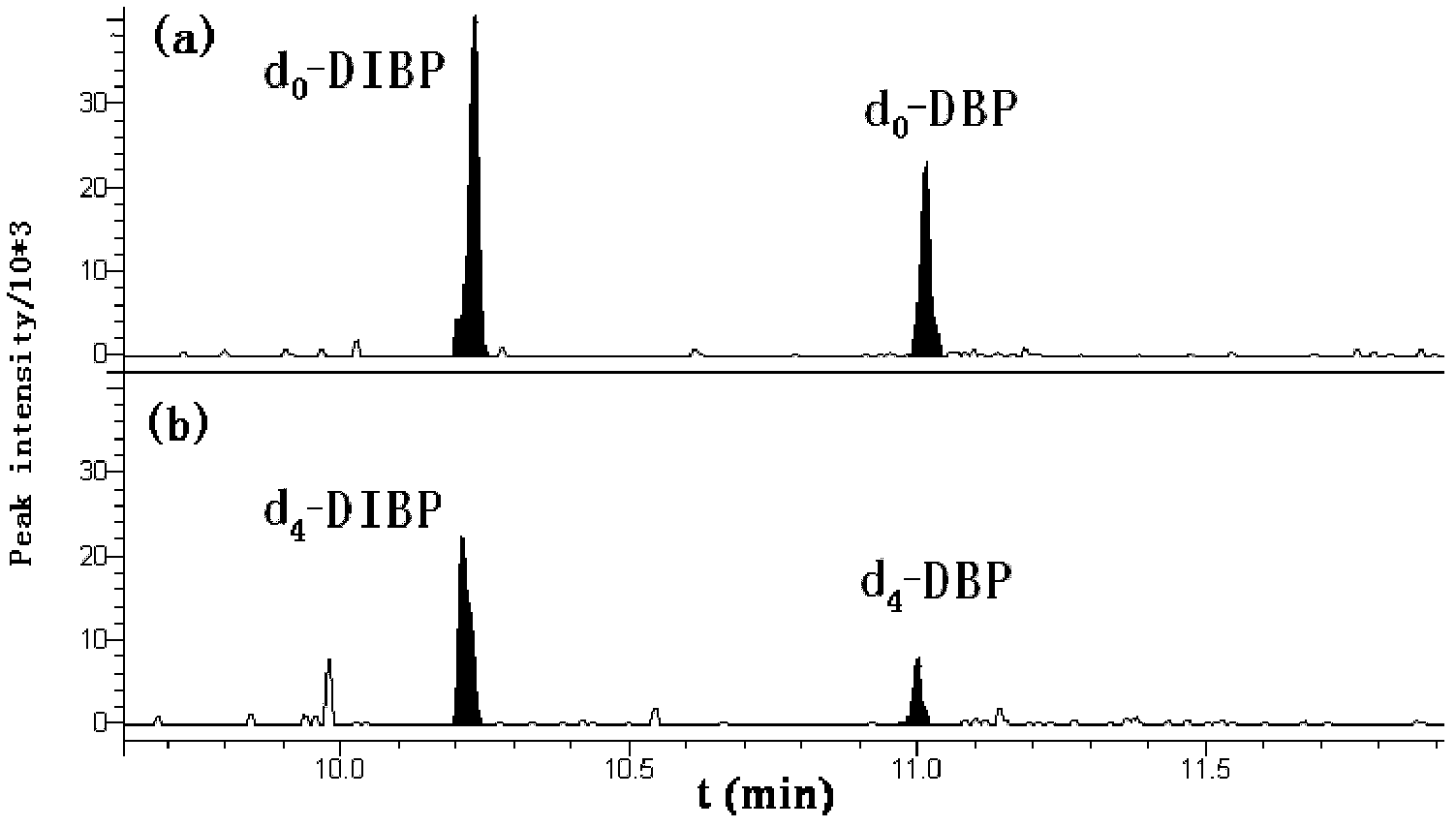

[0042] Example 1: Qualitative and quantitative analysis of plasticizers in the traditional Chinese medicine Xiaobupleurum granules

[0043] The operation steps are as follows:

[0044] Dilute the PAEs mixed standard solution (1000mg / L) into a series of concentrations: 100, 75, 50, 10, 5, 2, 1, 0.5mg / L, and dilute the PAEs isotope compound mixed solution (100mg / L) into 1.0-2.0mg / L internal standard solution. Take 1.0-2.0 μl of standard solution and internal standard solution for HS-SPME-GC-MS / MS experiment: heat the headspace bottle at 120-160°C for 15-25min, and use a static headspace solid-phase microextraction device ( 50 / 30μmDVB / CAR / PDMS Fiber) extraction for 5-15min, analysis at the inlet of 245-255℃ for 10-20min, and then GC-MS / MS analysis. The analysis results are shown in Table 1. At the same time, different collision energies are optimized, and appropriate collision energies are selected for different channels, as shown in the attached Figure 5 shown.

[0045] Ta...

Embodiment 2

[0053] Embodiment 2: Qualitative and quantitative analysis of plasticizer in coffee sample

[0054] The operation steps are as follows:

[0055] Dilute the PAEs mixed standard solution (1000mg / L) into a series of concentrations: 100, 75, 50, 10, 5, 2, 1, 0.5mg / L, and dilute the PAEs isotope compound mixed solution (100mg / L) into 1.0-2.0mg / L internal standard solution. Take 1-2 μl of standard solution and internal standard solution for HS-SPME-GC-MS / MS experiment: heat the headspace bottle at 120-160°C for 15-25min, use a static headspace solid-phase microextraction device (50 / 30μm DVB / CAR / PDMSFiber) extraction for 5-15min, analysis at the inlet of 245-255℃ for 10-20min, and then GC-MS / MS analysis. The analysis results are shown in Table 1. At the same time, different collision energies are optimized, and appropriate collision energies are selected for different channels, as shown in the attached Figure 5 shown.

[0056] Take 1.0-6.0g of sample coffee and put it into a 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com