Side pump all fiber and laser and amplifier based on all fiber

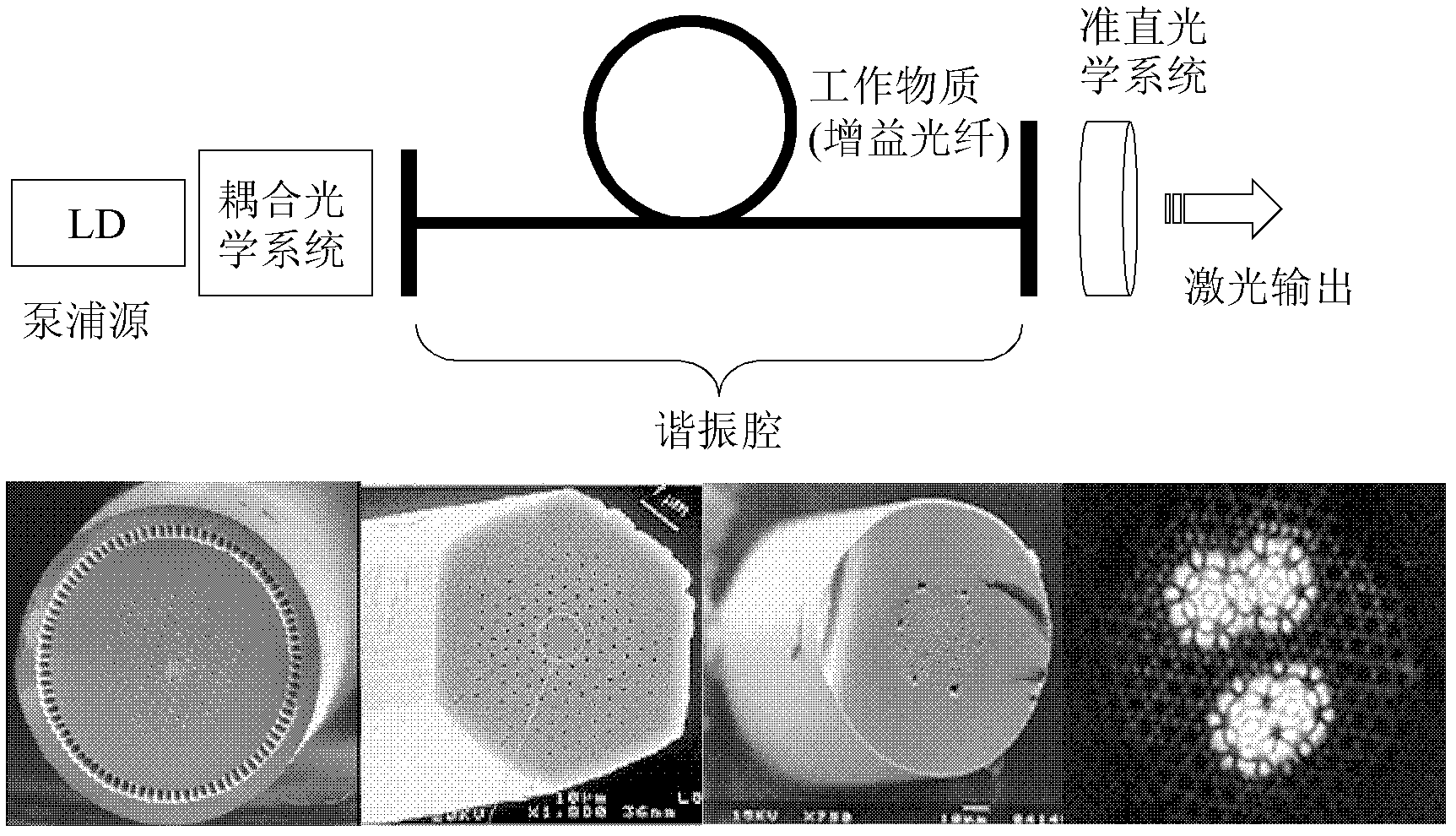

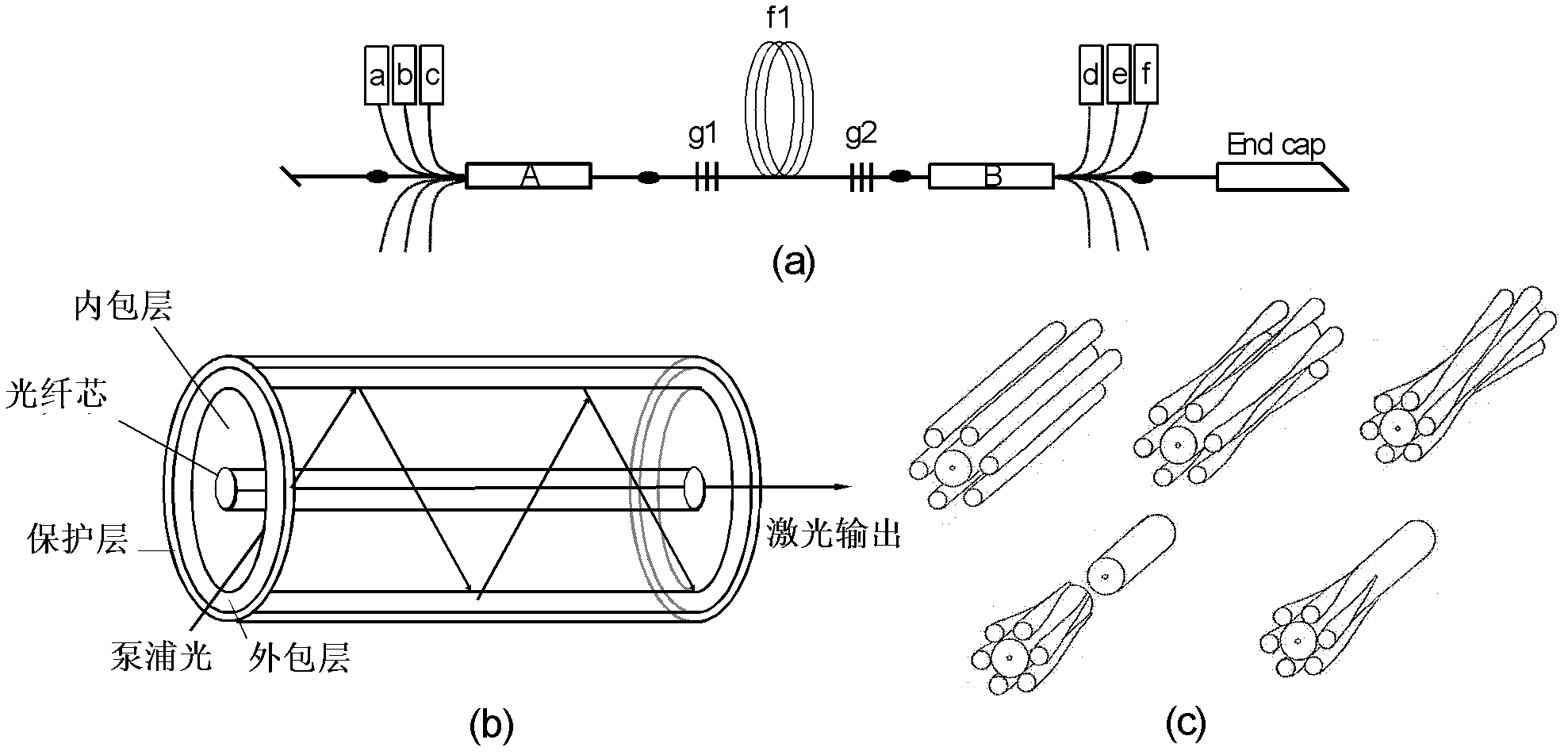

A side-pumped, all-fiber technology, applied in the direction of cladding fiber, optical waveguide light guide, optical waveguide coupling, etc., can solve the problem of infinite expansion of pump power of semiconductor lasers, and can not withstand the pumping power of several kilowatts. , Unable to achieve 10,000-watt fiber laser and other problems, to achieve the effect of good heat dissipation, improved output power, and high pump coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

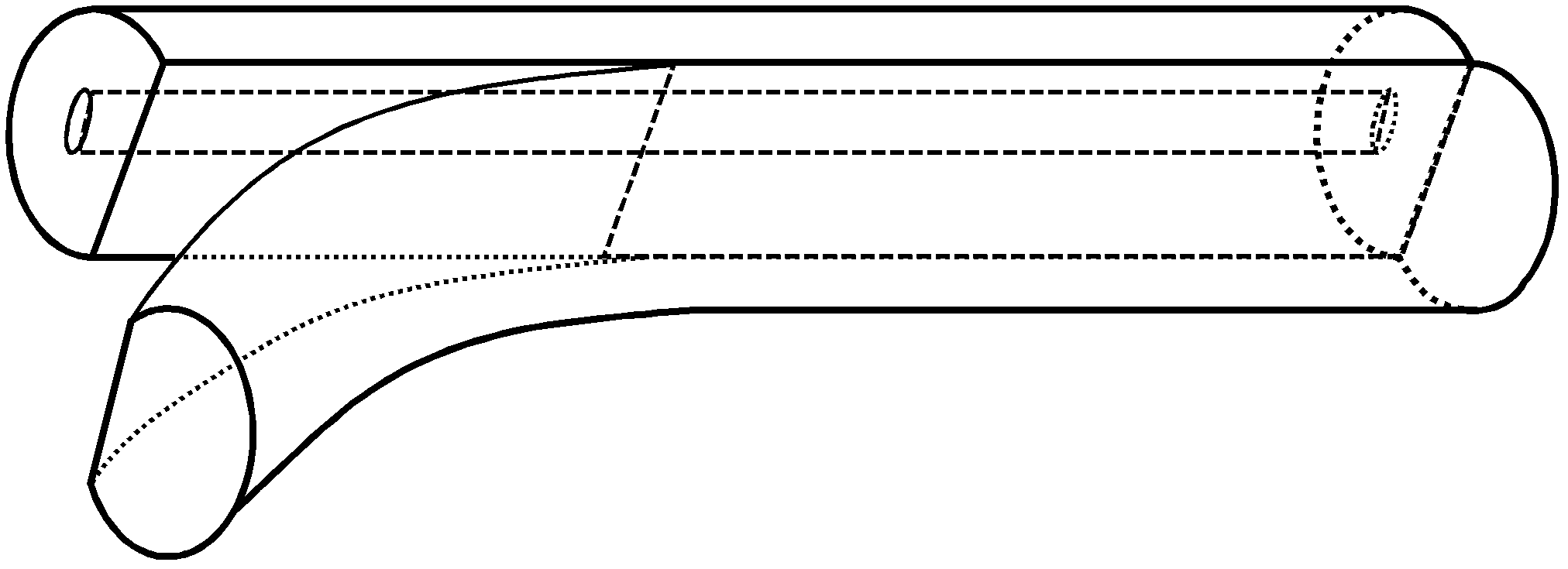

[0026] First of all, in the implementation method of the present invention, the pump structure of the fiber laser to the gain fiber has no melting point, and the pump coupling distance is extended from 1-2 cm in the traditional end-pumping technical solution to tens of meters. The transmission fiber of the pump laser is drawn into a D shape, the gain fiber is drawn into a D shape or an N-sided shape (this article will take a 6-sided shape as an example), and then the D-shaped transmission fiber bare fiber and the gain fiber bare fiber A certain plane coincides, and then side fusion splicing is realized. The simplest example is the side fusion splicing of D-shaped gain fiber and D-shaped pump transmission fiber to realize melting point-free parallel coupling side pumping, such as image 3 Shown. In this article, the gain fiber is a hexagonal prism as an example for illustration. The melting point-free parallel coupling side pump structure diagram of this (6+1) fiber is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com