Counter electrode of dye-sensitized solar battery, preparation method and applications of tungsten disulfide and molybdenum disulfide

A solar cell and dye-sensitized technology, which is applied in the field of dye-sensitized solar cells, can solve the problems that restrict the large-scale production and wide application of dye-sensitized solar cells, limited Pt reserves, and high price, and achieve high photoelectric conversion efficiency, Low price, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

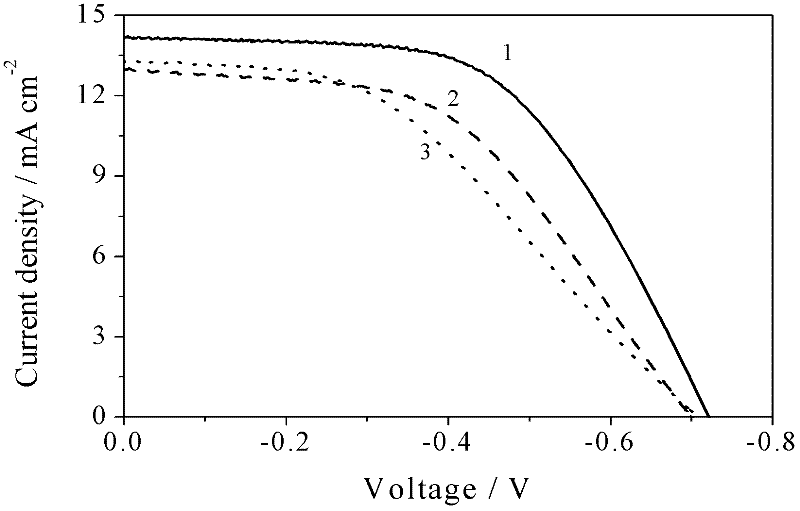

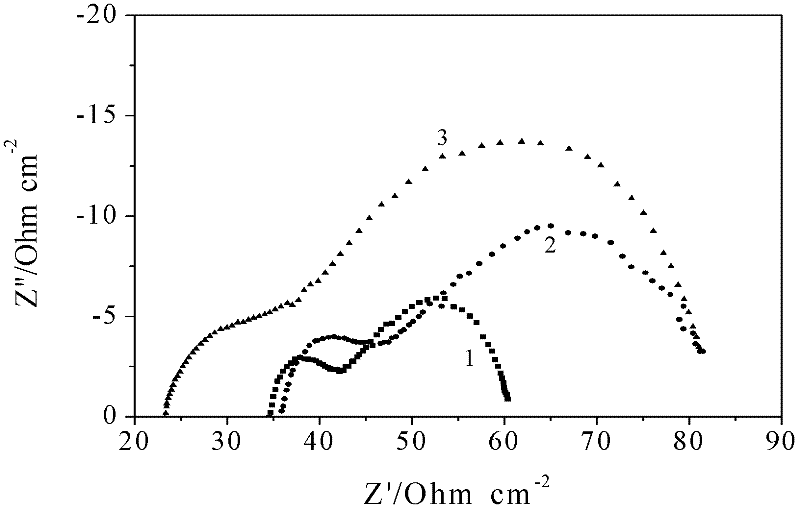

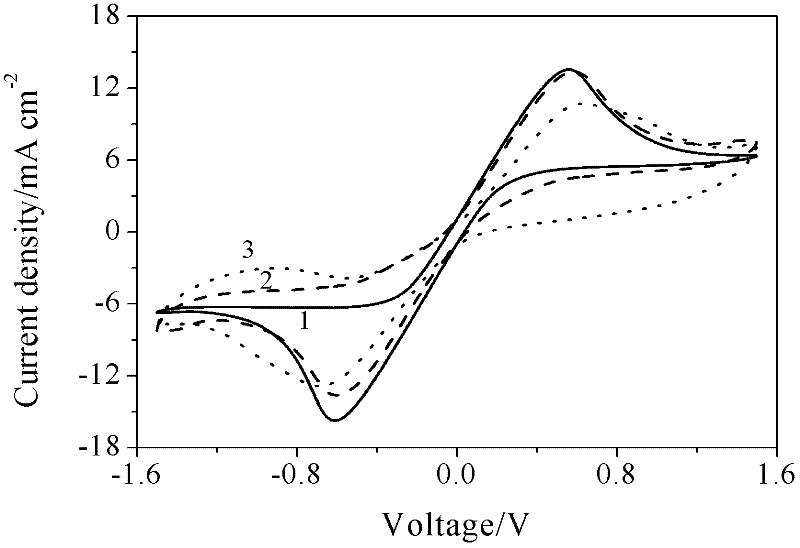

Examples

Embodiment 1

[0025] The counter electrode of dye-sensitized solar cell is made by the following steps:

[0026] (1) Disperse 0.6g tungsten disulfide particles uniformly in 1ml n-butanol to prepare system A;

[0027] (2) Take 0.03g of TiO with a particle size of 25nm 2 Nanocrystalline particles are uniformly dispersed in 1ml n-butanol to prepare system B;

[0028] (3) Dissolve 0.1g ethyl cellulose in 0.5ml n-butanol to prepare system C;

[0029] (4) Mix the A system, B system and C system, mechanically stir for 12 hours, ultrasonically disperse for 30 minutes, and grind for 1 hour to obtain a uniformly dispersed slurry D. The surface of the conductive substrate is scraped and sintered three times to obtain Dye-sensitized solar cell counter electrode; the specific steps of the first scraping and sintering treatment are: coating the slurry D on the surface of the transparent conductive glass substrate by the scraping method, and then sintering at 300°C for 30 minutes; the second The specific steps o...

Embodiment 2

[0031] The counter electrode of dye-sensitized solar cell is made by the following steps:

[0032] (1) Disperse 0.2g tungsten disulfide particles uniformly in 1ml n-butanol to prepare A system;

[0033] (2) Take 0.04g of TiO with a particle size of 25nm 2 Nanocrystalline particles and 0.06g of carbon nanoparticles with a diameter of 40nm were uniformly dispersed in 1ml of n-butanol to prepare system B;

[0034] (3) Dissolve 0.1g ethyl cellulose in 0.5ml n-butanol to prepare system C;

[0035] (4) Mix the A system, the B system and the C system, mechanically stir for 12 hours, ultrasonically disperse for 30 minutes, and grind for 1 hour to obtain a uniformly dispersed slurry D. Perform three screen printing and sintering treatments on the surface of the conductive substrate. Obtain the dye-sensitized solar cell counter electrode; the specific steps of the first screen printing and sintering treatment are: use the screen printing method to coat the paste D on the surface of the transpar...

Embodiment 3

[0037] The counter electrode of dye-sensitized solar cell is made by the following steps:

[0038] (1) Disperse 0.6g tungsten disulfide particles uniformly in 1ml n-butanol to prepare system A;

[0039] (2) Take 0.03g of TiO with a particle size of 25nm 2 Nanocrystalline particles and 0.03g of carbon nanoparticles with a diameter of 40nm are uniformly dispersed in 1ml of n-butanol to prepare system B;

[0040] (3) Dissolve 0.1g ethyl cellulose in 0.5ml n-butanol to prepare system C;

[0041] (4) Mix the A system, B system and C system, mechanically stir for 12 hours, ultrasonically disperse for 30 minutes, and grind for 1 hour to obtain a uniformly dispersed slurry D. The surface of the conductive substrate is scraped and sintered three times to obtain Dye-sensitized solar cell counter electrode; the specific steps of the first scraping and sintering treatment are: coating the slurry D on the surface of the transparent conductive glass substrate by the scraping method, and then sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com