Protection circuit of converter power component

An overcurrent protection circuit and power component technology, applied in the field of high-voltage power, can solve the problems of large switch volume, slow closing speed, and increased cost, and achieve the effect of simple protection circuit, reduced complexity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

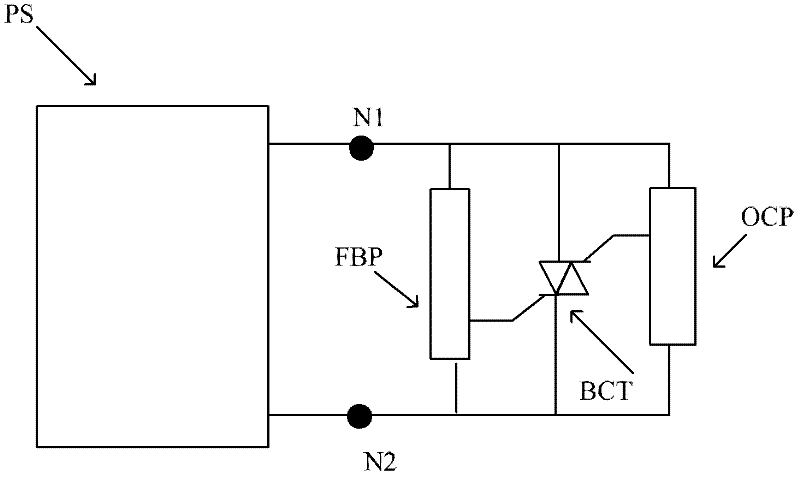

[0037] This embodiment uses only one power component for detailed description, such as image 3 Shown. In this embodiment, the two ends of the power module (PS) N 1 , N 2 Parallel fault bypass circuit FBP, thyristor BCT and overcurrent protection circuit (OCP). The fault bypass circuit means that when the power component fails, the fault bypass circuit triggers the thyristor to turn on the thyristor to bypass the power component. The overcurrent protection circuit is when the power component has an overcurrent phenomenon, the overcurrent protection circuit triggers the thyristor to turn on the thyristor to protect the power component. The thyristor is a crimp type bidirectional control thyristor, the gate I of the bidirectional control thyristor is connected to the fault bypass circuit; the gate II of the thyristor is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com