Microwave and hot air combined water removing method for green tea

A technology of deenzyming and microwave, which is applied in the direction of tea treatment before extraction, can solve the problems of insufficient volatilization of aroma substances with low boiling point, insufficient heat effect of microwave deenzyming, etc. The method is simple, easy to manufacture, and the time for degreening is short. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

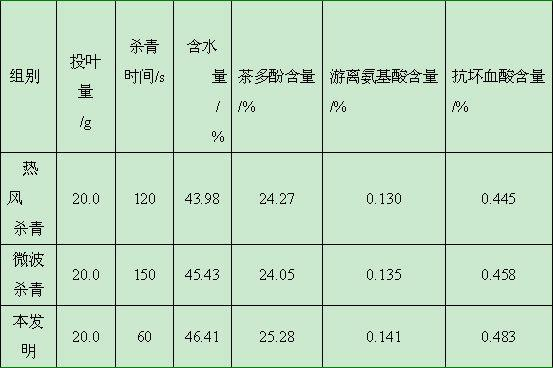

Image

Examples

Embodiment 1

[0017] A method for combining green tea with microwave and hot air, comprising the following steps:

[0018] (1) Use young tea buds or leaves that meet the picking standards and have a certain degree of tenderness as fresh tea leaves, and spread the fresh tea leaves in a cooling trough to cool them. The thickness of the fresh tea leaves is 3-5cm. Cooling time is 4-6 hours, stir once every two hours, when the water content of the fresh tea leaves is 65%-70%, the leaves are soft and fragrant, the green leaves are ready to be taken out;

[0019] (2) Use a microwave and hot air combined greening machine to kill the green leaves after cooling, first turn on the hot air switch, and preheat the hot air temperature at 20-160°C;

[0020] (3) When the temperature of the green machine cavity reaches the preset temperature, start to put in the green leaves to be fixed, and at the same time turn on the microwave switch, adjust the microwave power to 0-2000W; spread the green leaves to be f...

Embodiment 2

[0025] A method for combining green tea with microwave and hot air, comprising the following steps:

[0026] (1) Fresh tea leaves are used as raw materials, and the picking standard is mainly 1 bud and 2 leaves, as well as pairs of leaves with the same tenderness. Put the fresh tea leaves in a cooling tank to cool them. The time is 5 hours, and it is stirred once every two hours. When the water content of the fresh leaves is 68%, the leaves are soft and fragrant, the fresh leaves are taken out, and the leaves are ready to be greened;

[0027] (2) Use a combination of microwave and hot air to fix the greens, first turn on the hot air switch, adjust the temperature of the hot air to 50°C, and preheat;

[0028] (3) When the temperature of the greening machine chamber reaches 50°C, start to put in fresh leaves, and spread the fresh leaves on the conveyor belt of the greening machine. At the same time, turn on the microwave switch, adjust the microwave power to 1400W, and adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com