Modified activated carbon and method for regenerating active carbon by photocatalysis of gas-solid fluidized bed

A technology of activated carbon and fluidized bed, which is applied in the field of activated carbon and its regeneration. It can solve the problems of changes in the chemical structure of the carbon surface, large loss of activated carbon, and secondary pollution of equipment, and achieve the effects of small loss of activated carbon, simple regeneration device, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, add a certain amount of titanium tetrachloride to the mixture of ethanol, glacial acetic acid and a small amount of water, then add an appropriate amount of thiourea, and stir for a period of time to obtain S-TiO 2 Then add a certain amount of PEG to the sol, stir for 20 minutes, add a certain amount of activated carbon (AC), continue to stir for 1 hour, and ultrasonically disperse for 0.5 hours to obtain a mixture of AC and sol. Calcined in a furnace at 350°C for 3 hours to obtain modified activated carbon. After analysis, S-TiO 2 The mass fraction of sulfur in the medium is 0.9% (elemental analysis), and the modified activated carbon S-TiO 2 The load is 5%.

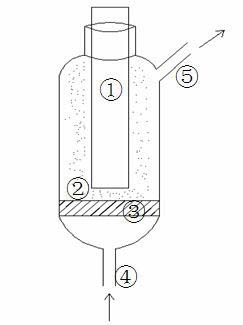

[0037] The activated carbon after adsorption saturation is regenerated by gas-solid fluidized bed photocatalytic method, and the photocatalytic regeneration is carried out in the surrounding figure 1 performed in the experimental setup shown. The experimental device used includes a reaction container,...

Embodiment 2

[0043] First, add a certain amount of titanium tetraisopropoxide to the mixture of ethanol, glacial acetic acid and a small amount of water, then add an appropriate amount of sulfur, and stir for a period of time to obtain S-TiO 2 Sol, then add a certain amount of PEG to the sol, after stirring for 50min, add a certain amount of AC, and ultrasonically disperse for 0.5h to obtain a mixture of AC and sol, dry at 90°C, and finally calcinate at 400°C for 2h in a programmable temperature control furnace , to obtain modified activated carbon. After analysis, S-TiO 2 The mass fraction of sulfur in the medium is 1.0% (elemental analysis), and the modified activated carbon S-TiO 2 The load is 6.5%.

[0044] The photocatalytic regeneration of activated carbon after adsorption saturation is figure 1 It is carried out in the device, take out the ultraviolet lamp, put the activated carbon into the reaction instrument from the upper port, spread it on the air distributor, insert the ult...

Embodiment 3

[0046] First, add a certain amount of tetrabutyl titanate to the mixture of ethanol, glacial acetic acid and a small amount of water, then add an appropriate amount of thiourea, and stir for a period of time to obtain S-TiO 2 Then add a certain amount of PEG to the sol, stir for 35 minutes, add a certain amount of AC, and stir for 50 minutes to obtain a mixture of AC and sol, dry it at 80°C, and finally calcinate it in a temperature-controlled furnace at 450°C for 1.5h. Obtain modified activated carbon. After analysis, S-TiO 2 The mass fraction of sulfur in the medium is 1.2% (elemental analysis), and the modified activated carbon S-TiO 2 The load is 10%.

[0047] The photocatalytic regeneration of activated carbon after adsorption saturation is figure 1 It is carried out in the device, take out the ultraviolet lamp, put the activated carbon into the reaction instrument from the upper port, spread it on the air distributor, insert the ultraviolet lamp into the instrument, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com