Injection molding method and equipment for single polymer composite product

A technology of injection molding and composite materials, applied in coating and other directions, can solve the problems of difficulty in mass production, single product shape, long molding cycle, etc., and achieve the effects of high production efficiency, high product strength, and short molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

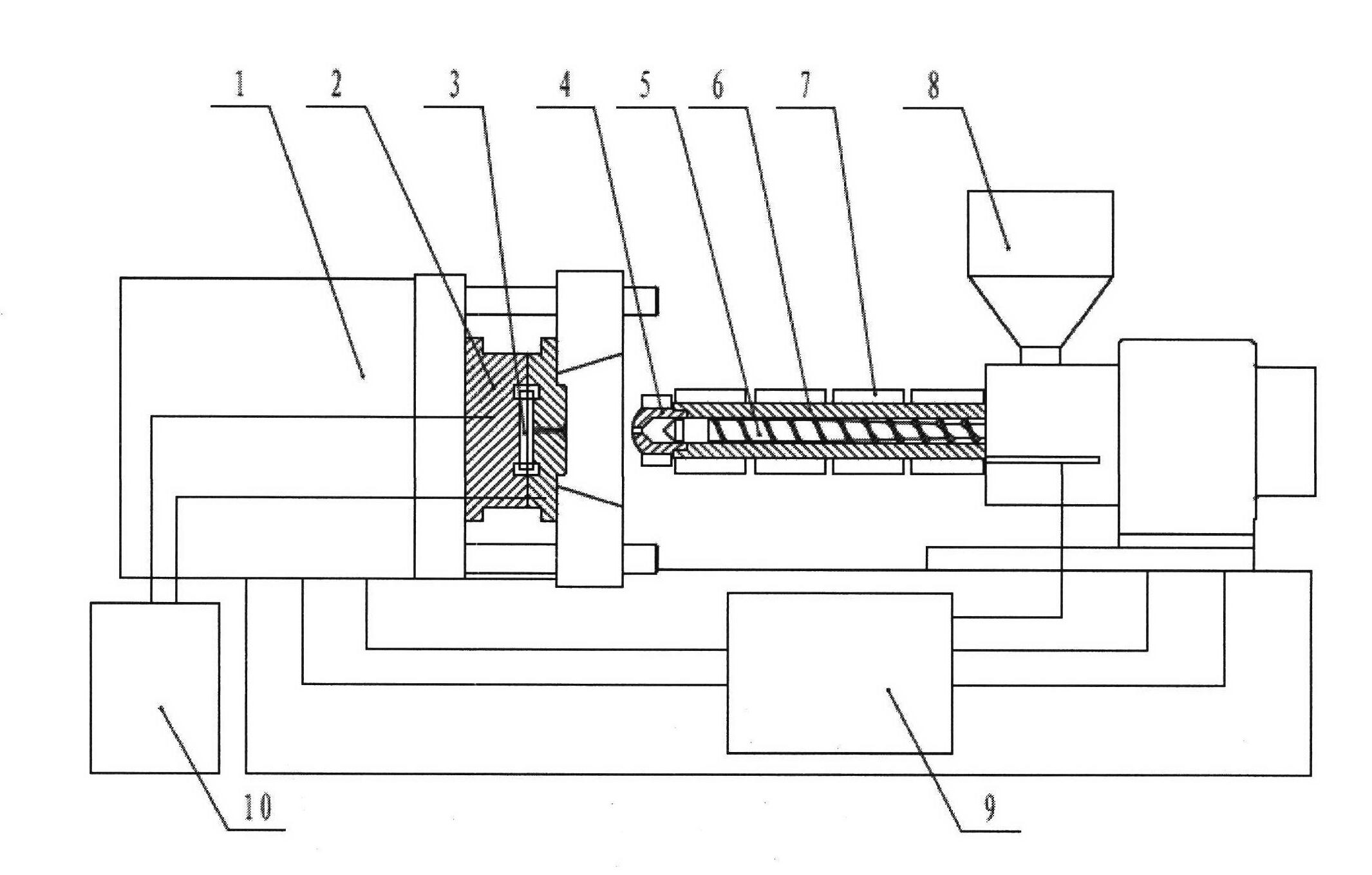

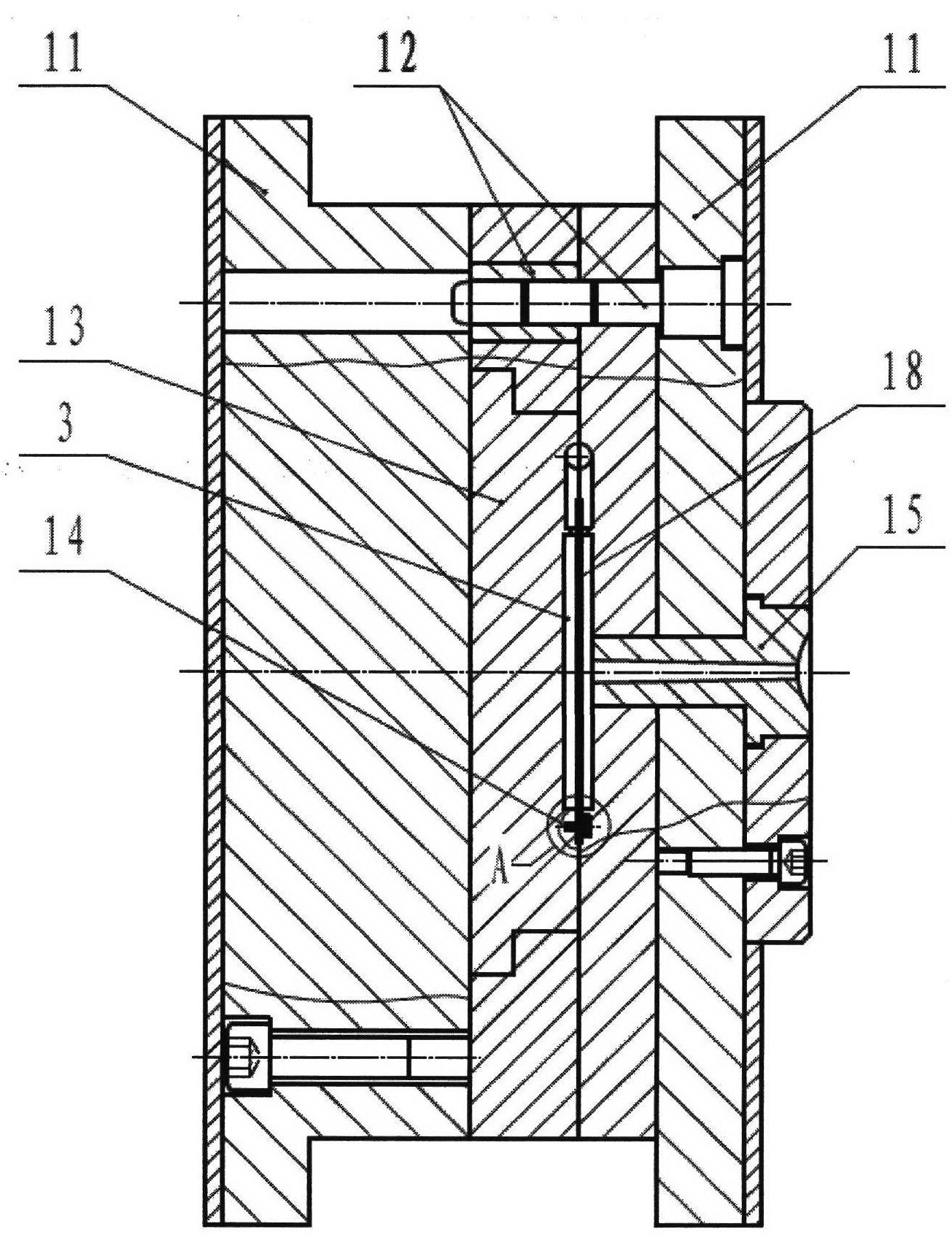

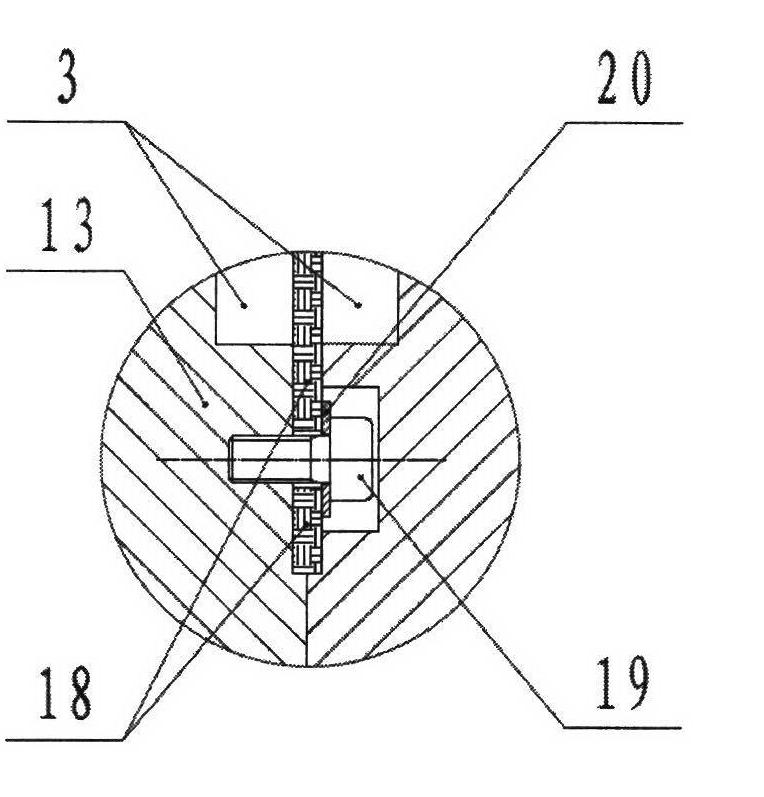

[0046] A single polymer composite product injection molding equipment, the injection molding equipment is composed of an injection molding machine and a mold 2, wherein the injection molding machine adopts a conventional injection molding machine (AE80-32H, Guangzhou CNC Equipment Co., Ltd.), mainly composed of an injection system, a synthetic Mold system 1, transmission system, heating and cooling system and control system 9. The injection system is mainly composed of hopper 8, barrel 6, screw 5 and nozzle 4. Mold 2 is mainly composed of molding parts 13, pouring system 15, guide parts 12, It consists of a temperature adjustment system 10, an exhaust system, a support member 11 and a fixing mechanism 14. The outer wall of the barrel 6 is provided with an electric heating coil 7 of a heating and cooling system as a heating device. The barrel 6 is provided with a hopper 8 and a screw 5 inside. The front end is connected to the nozzle 4, and the fixing mechanism 14 of the mold 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com