Microcomponent vacuum packaging method

A technology for vacuum packaging and micro-devices, which is applied to electric solid-state devices, semiconductor devices, micro-structure devices, etc., can solve the problems of reducing packaging efficiency, taking a long time, and increasing the volume of devices, achieving a simple and effective packaging method and saving packaging costs. , to achieve the effect of electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention comprises the following steps:

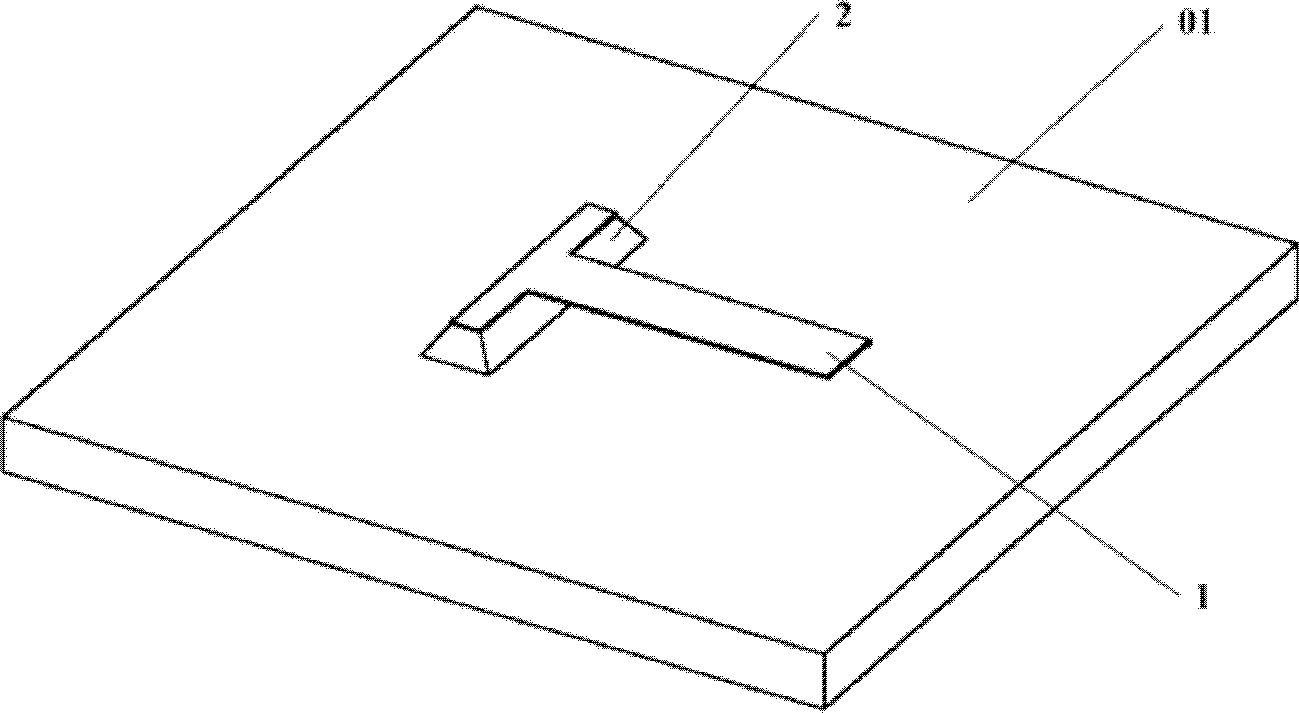

[0029] see figure 1 , using micromachining technology to process on the lower silicon wafer 01 such as figure 1 The silicon island 2 shown, the MEMS movable structure 1 and the attached metal electrodes and leads;

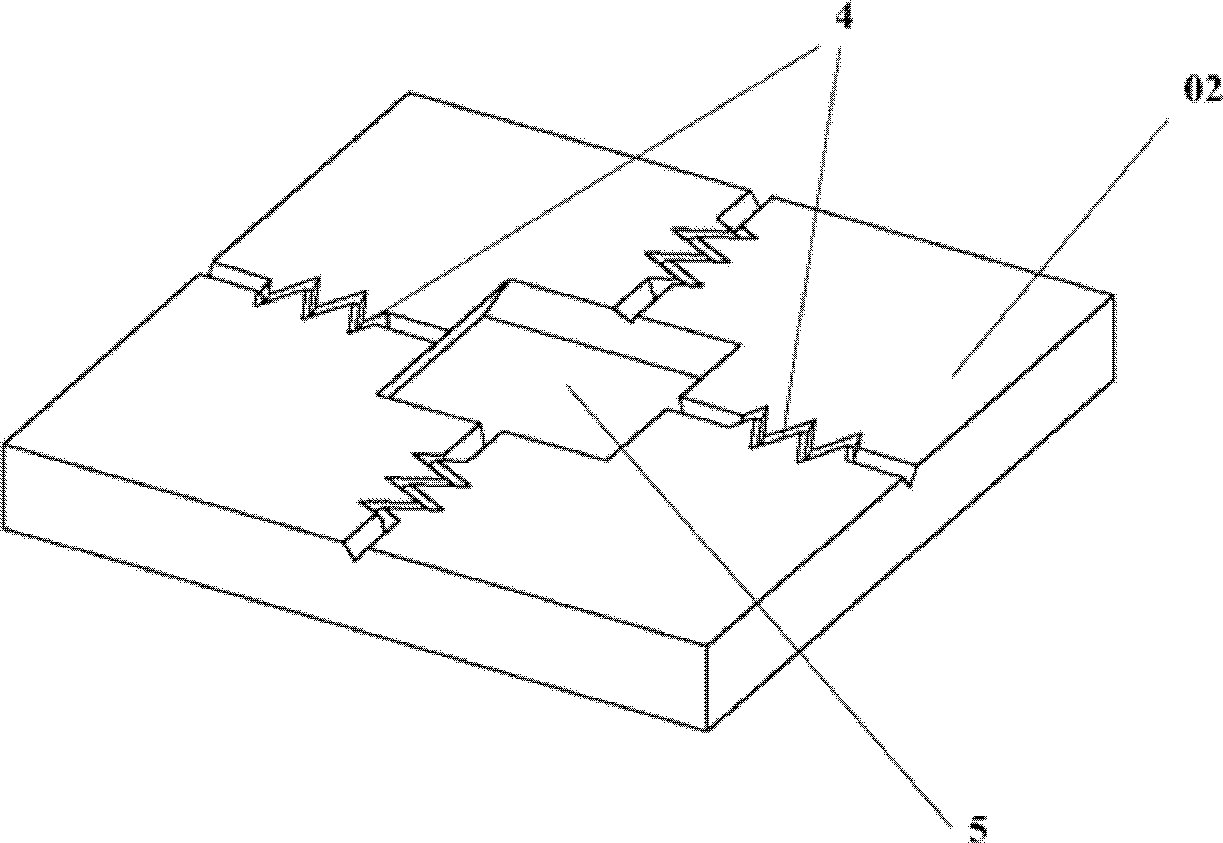

[0030] see figure 2 , through anisotropic wet etching of the silicon wafer, a trapezoidal through hole 5 is etched on the front side of the upper silicon wafer 02. When the glass paste is bonded, the movable mechanism 1 is placed in the trapezoidal through hole 5; The size of the flow channel 4 is on the order of microns, and the shape of the micro flow channel 4 is in the form of an "S" broken line, which is made by wet etching or ICP dry etching technology;

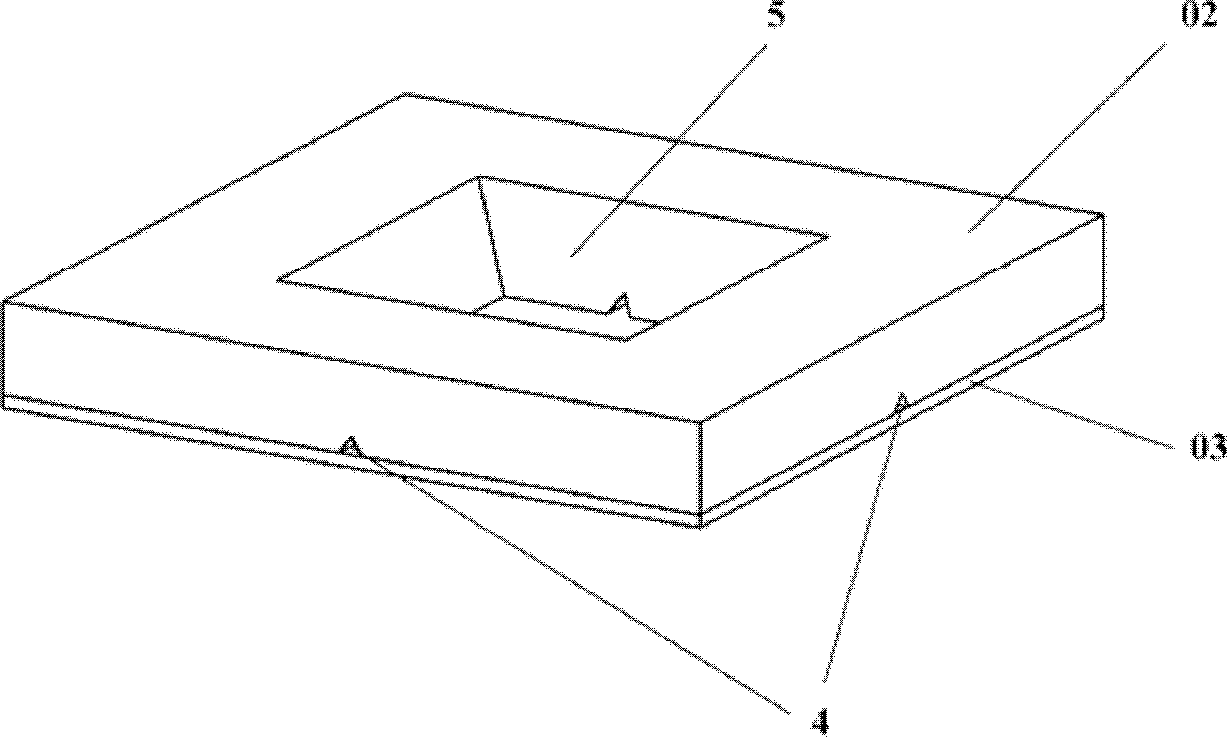

[0031] see image 3 , the cover plate 03 is made of 7740 glass, and the upper silicon wafer 02 and the glass cover plate 03 are bonded together by anodic bonding technology;

[0032] see Figure 4~6 , the front of the upper silicon wafer 02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com