Method of catalytic reduction treatment on nitrobenzene wastewater by utilizing Korean pine source charcoal

A technology for nitrobenzene wastewater and charcoal, which is applied in the fields of reduced water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effects of mild reaction system, simple and easy method, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

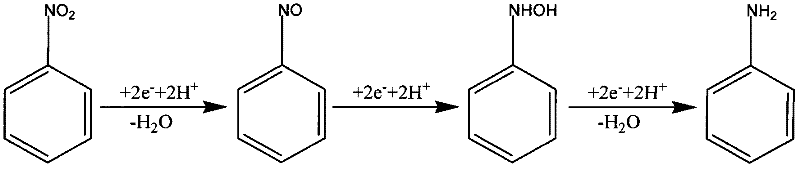

Method used

Image

Examples

Embodiment 1

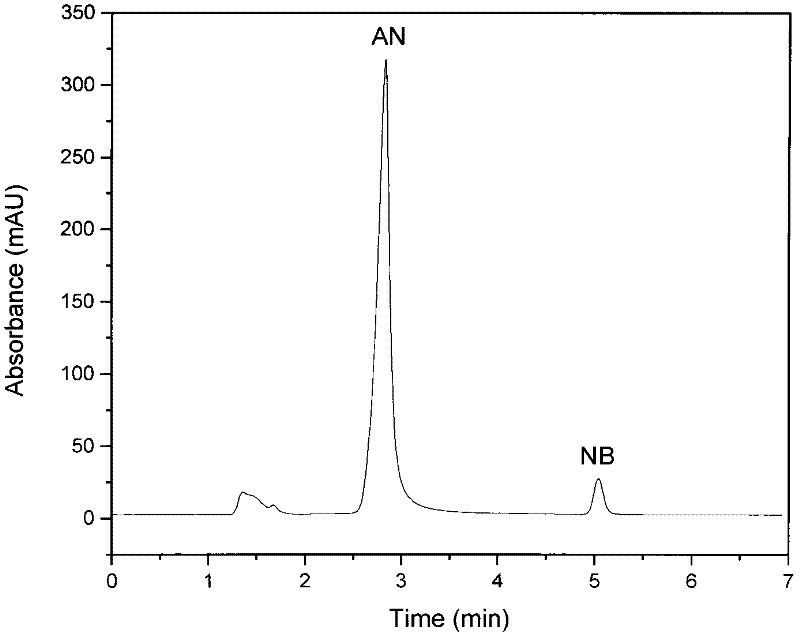

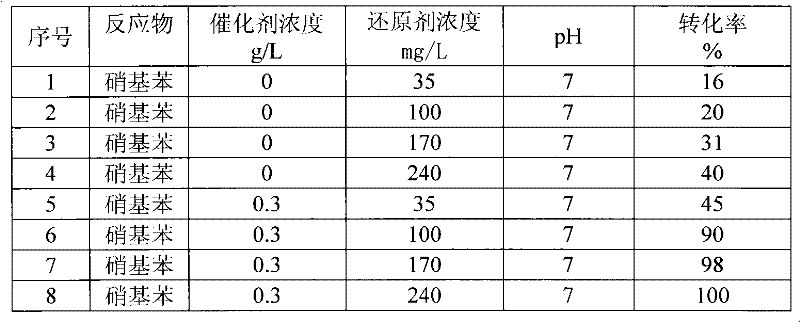

[0026] Embodiment 1: Sulfide reduction nitrobenzene

[0027] In 8 200ml anaerobic simulated reactors, adding pH is 7 phosphate buffers and concentration is the nitrobenzene waste water of 100mg / L, is filled with high-purity nitrogen in reactor (to remove the oxygen in the reaction system, Form anaerobic environment), add 35mg / L, 100mg / L, 170mg / L, 240mg / L reducing agent sulfide respectively in the reactor, then, do not add catalyst in No. 1-4 reactor, in No. 5-8 60 mg of Korean pine source charcoal was respectively added into the reactor as a reaction catalyst. The reactor was sealed and placed in a rotary oscillator, and the reaction was shaken at a speed of 150-200 rpm at normal temperature and pressure for 72 hours. After the reaction, the reduced product was aniline. The conversion rate of nitrobenzene is shown in Table 1.

[0028] The conversion rate of nitrobenzene under the hydrogen sulfide reduction condition of table 1

[0029]

Embodiment 2

[0030] Embodiment 2: Reductive conversion of nitrobenzene under different pH conditions

[0031] The difference from Examples 1 and 2 is that different buffers are added to different reactors so that the pH of the reaction system is 1, 3, 5, 7, 9, 13, 14 respectively, and after 72 hours of reaction The conversion rate of nitrobenzene is shown in Table 2.

[0032] The conversion rate of nitrobenzene under different pH values in table 2

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com