Additive and application thereof for reducing sintering temperature of piezoceramic

A technology of piezoelectric ceramics and sintering temperature, which is applied in the field of additives and its use to reduce the sintering temperature of piezoelectric ceramics, can solve the problems of complex process, high cost, and different formula composition, and achieve simplified process, low cost and simple composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with embodiment now.

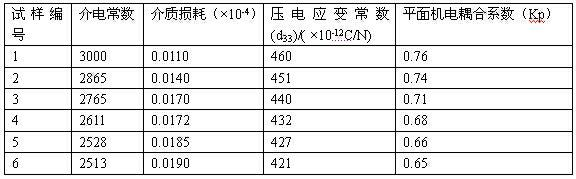

[0024]Tables 1 and 2 provide 6 formulations of two groups of embodiments of the present invention.

[0025] With niobium zinc-niobium nickel-lead zirconate titanate (PZN-PNN-PZT) as the basic formula system, niobium zinc-niobium nickel-lead zirconate titanate is: Pb(Zn 1 / 3 Nb 2 / 3 ) 0.1 (Ni 1 / 3 Nb 2 / 3 ) 0.1 Zr 0.47 Ti 0.33 ), with a weight of 100 grams.

[0026] The main raw materials of the 6 formulas of the second group of examples are the common raw materials of piezoelectric ceramics, and the ingredients are formulated according to the formula. The prepared materials are mixed with absolute ethanol as the medium and ball milled with a planetary ball mill. The materials: balls: ethanol = 1: 3: (0.6 ~0.9), ball milling time is 6~8 hours, drying to get dry powder, sieving, pre-calcining, using planetary ball mill ball milling, material: ball: water = 1:3: (0.6~0.9), drying, pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com