Preparation method of amido polycarboxylic water-reducing agent

An amide type polycarboxylic acid and water reducing agent technology, applied in the field of concrete admixtures, can solve the problems of harsh conditions and difficult control, and achieve the effects of high water reduction rate, low water-cement ratio and freight saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

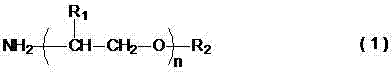

Method used

Image

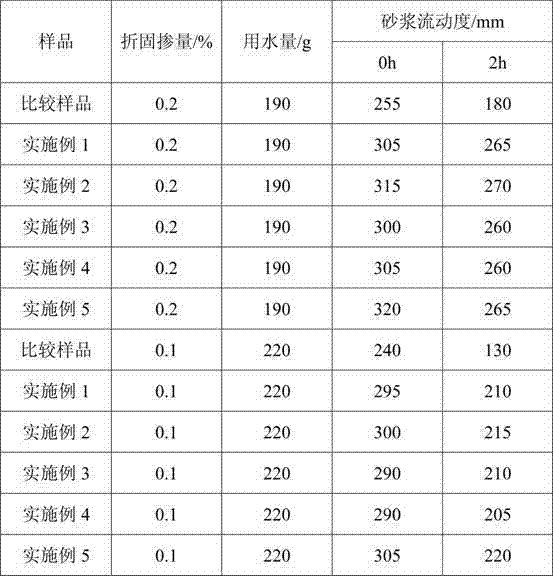

Examples

Embodiment 1

[0033] Add 235.5g of water into the three-necked flask, start stirring, and raise the temperature to 75°C-77°C. At the same time, the initiator solution obtained by dissolving 2.5g potassium persulfate in 30.0g water, the chain transfer agent solution obtained by dissolving 18.0g isopropanol in 60.0g water, and the solution obtained by dissolving 400.0g acrylic acid and 100.0g methacrylic acid in The monomer solution obtained in 154.0 g of water was added dropwise for 3 hours, and after the dropwise addition was completed, it was incubated for 2 hours to obtain a carboxyl group-containing polymer. Then add 1955.0g of amino-terminated polyether monomer A and 1000.0g of polyethylene glycol monomethyl ether with a molecular weight of 1000 into the above-mentioned three-necked flask, raise the temperature, and react under the conditions of 130°C to 140°C and -0.07Mpa to -0.08Mpa After 2 hours, cool down to 40°C and add 900.0g of 20% sodium hydroxide to bring the pH value of the so...

Embodiment 2

[0035] Add 235.5g of water into the three-necked flask, start stirring, and raise the temperature to 65°C-67°C. At the same time, the initiator solution obtained by dissolving 12.0g ammonium persulfate in 30.0g water, the chain transfer agent solution obtained by dissolving 6.0g hypophosphorous acid in 60.0g water, and the solution obtained by dissolving 300.0g acrylic acid and 200.0g methacrylic acid in 154.0 g were added dropwise. The monomer solution obtained in g water, the dropwise addition time is 5 hours, and after the dropwise addition is completed, it is incubated for 1 hour to obtain a carboxyl-containing polymer. Add 2490.0g of amino-terminated polyether monomer B, 810.0g of polyethylene glycol monoethyl ether with a molecular weight of 400, and 19.4g of catalyst p-toluenesulfonic acid into the above-mentioned three-necked flask. Mpa~-0.09Mpa conditions for 6 hours, lower the temperature to 50°C and add 560.0g of potassium hydroxide with a concentration of 30%, the ...

Embodiment 3

[0037] Add 235.5g of water into the three-necked flask, start stirring, and raise the temperature to 85°C-87°C. Add dropwise at the same time the initiator solution obtained by dissolving 9.0g hydrogen peroxide in 30.0g water, the chain transfer agent solution obtained by dissolving 3.0g mercaptoethanol in 60.0g water, and the solution obtained by dissolving 350.0g acrylic acid and 150.0g methacrylic acid in 154.0 g The monomer solution obtained in g water, the dropwise addition time is 2 hours, and after the dropwise addition is completed, it is incubated for 3 hours to obtain a carboxyl-containing polymer. Then add 3000.0g of amino-terminated polyether monomer C and 500.0g of polyethylene glycol monopropyl ether with a molecular weight of 2000 into the above-mentioned three-necked flask, raise the temperature, and react under the conditions of 160°C to 170°C and -0.03Mpa to -0.04Mpa After 7 hours, cool down to 30°C and add 445.0g of triethanolamine with a concentration of 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com