Thermosetting reflection thermal insulation coating and preparation method thereof

A reflective heat-insulating coating, heat-setting technology, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of less heat-reflecting functional pigments, affecting solar heat reflectivity, and adding too much filler to achieve shrinkage The effect of low rate, good stain resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

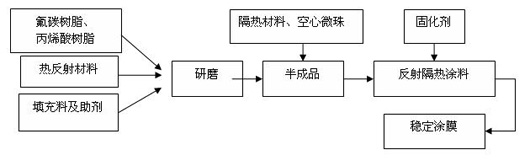

Method used

Image

Examples

Embodiment 1

[0032]First, 100 kg of fluorocarbon resin, 30 kg of acrylic resin, 40 kg of rutile titanium dioxide, 20 kg of silicon dioxide, 0.5 kg of dispersant BYK-116, 0.5 kg of leveling agent BYK-358N, and 0.4 kg of defoamer BYK-141 , Anti-sedimentation agent BYK-410 0.6 kg is uniformly mixed in a high-speed disperser, the speed is 1000-1400 rpm, and the time is 15 minutes; the mixed material is ground three times by a sand mill, and the time for each time is about 1 hour. When the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished thermosetting reflective heat insulation can be obtained coating. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

Embodiment 2

[0034] First, 120 kg of fluorocarbon resin, 35 kg of acrylic resin, 50 kg of rutile titanium dioxide, 25 kg of silicon dioxide, 0.6 kg of dispersant BYK-116, 0.6 kg of leveling agent BYK-358N, and 0.5 kg of defoamer BYK-141 , Anti-sedimentation agent BYK-410 0.6 kg is uniformly mixed in a high-speed disperser, the speed is 1000-1400 rpm, and the time is 15 minutes; the mixed material is ground three times by a sand mill, and the time for each time is about 1 hour. When the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished thermosetting reflective heat insulation can be obtained coating. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

Embodiment 3

[0036] First, 150 kg of fluorocarbon resin, 40 kg of acrylic resin, 60 kg of rutile titanium dioxide, 30 kg of silicon dioxide, 0.8 kg of dispersant BYK-116, 0.8 kg of leveling agent BYK-358N, 0.6 kg of defoamer BYK-141 kg, anti-sedimentation agent BYK-410 is 0.8 kg, and is uniformly mixed in a high-speed disperser at a speed of 1000-1400 rpm for 15 minutes; the mixed material is ground three times by a sand mill, and the time for each pass is about 1 Hours, when the fineness reaches below 25 microns, it can be used as a semi-finished product; then add the measured hollow microspheres to the semi-finished product, and then stir for 20 minutes at a speed of 600-800 rpm, and finally the finished heat-cured reflector can be obtained. Insulation paint. When used, the weight ratio is: thermosetting reflective heat-insulating coating: curing agent = 100:10; add biuret, stir well, and use after 30 minutes of curing.

[0037]

[0038] Comparison of the characteristics of reflective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com