Divalent-bismuth-ion-doped strontium borate fluorescent material and preparation method thereof

A technology of fluorescent materials and bismuth ions, which can be applied in the fields of luminescent materials, chemical instruments and methods, etc., and can solve the problems of few reports on doped luminescent materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

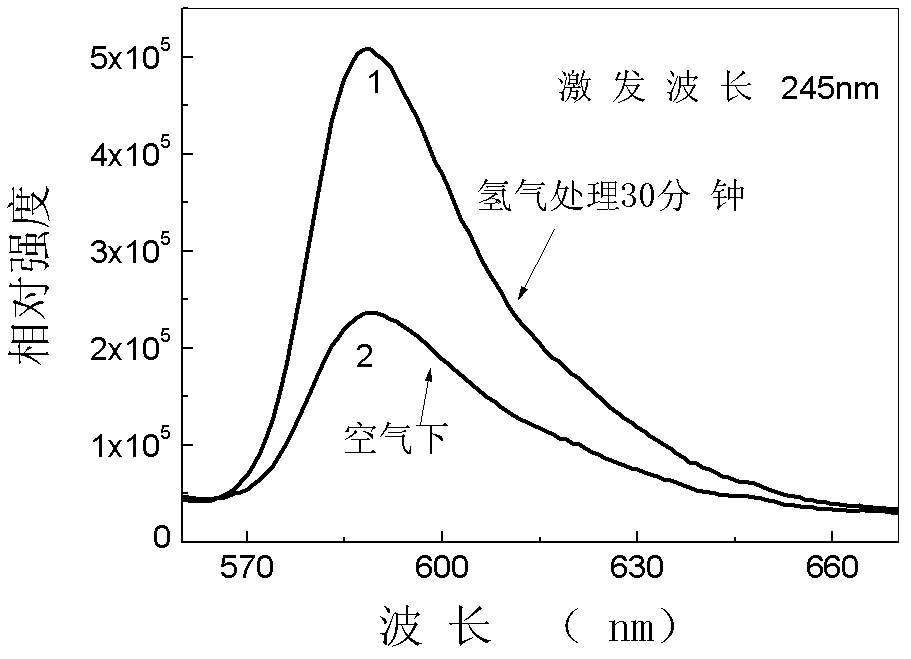

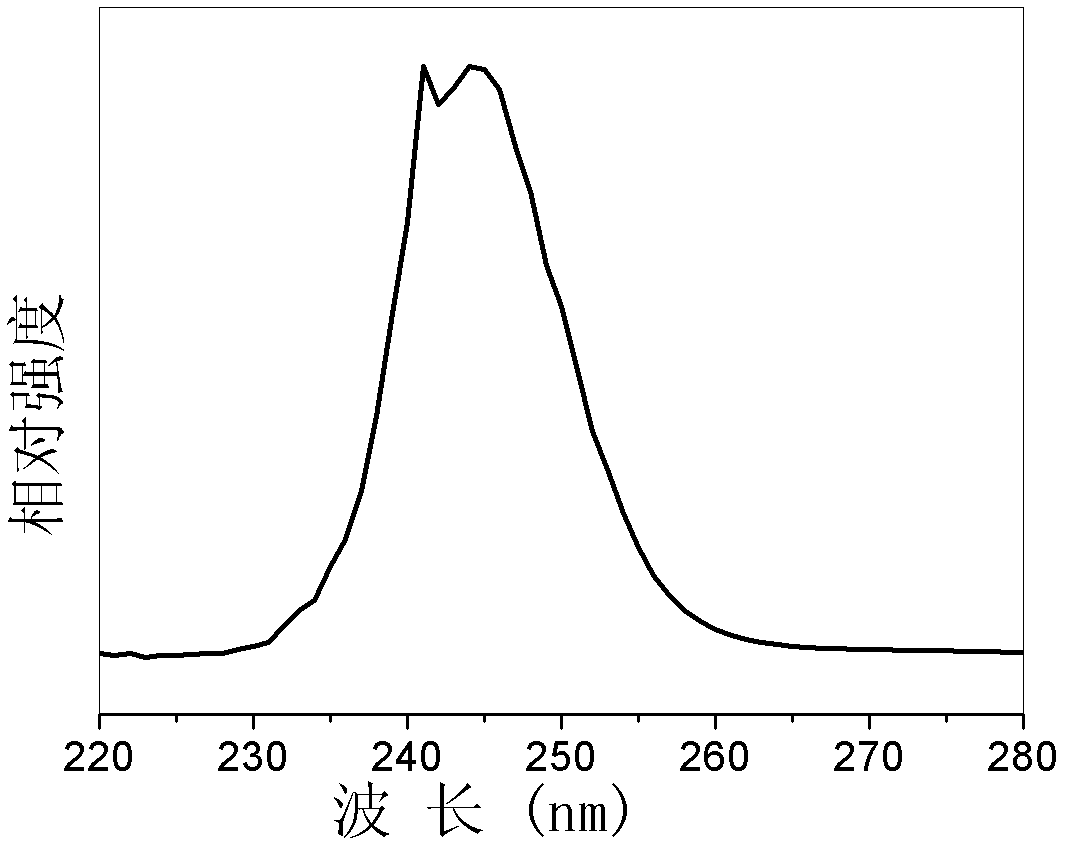

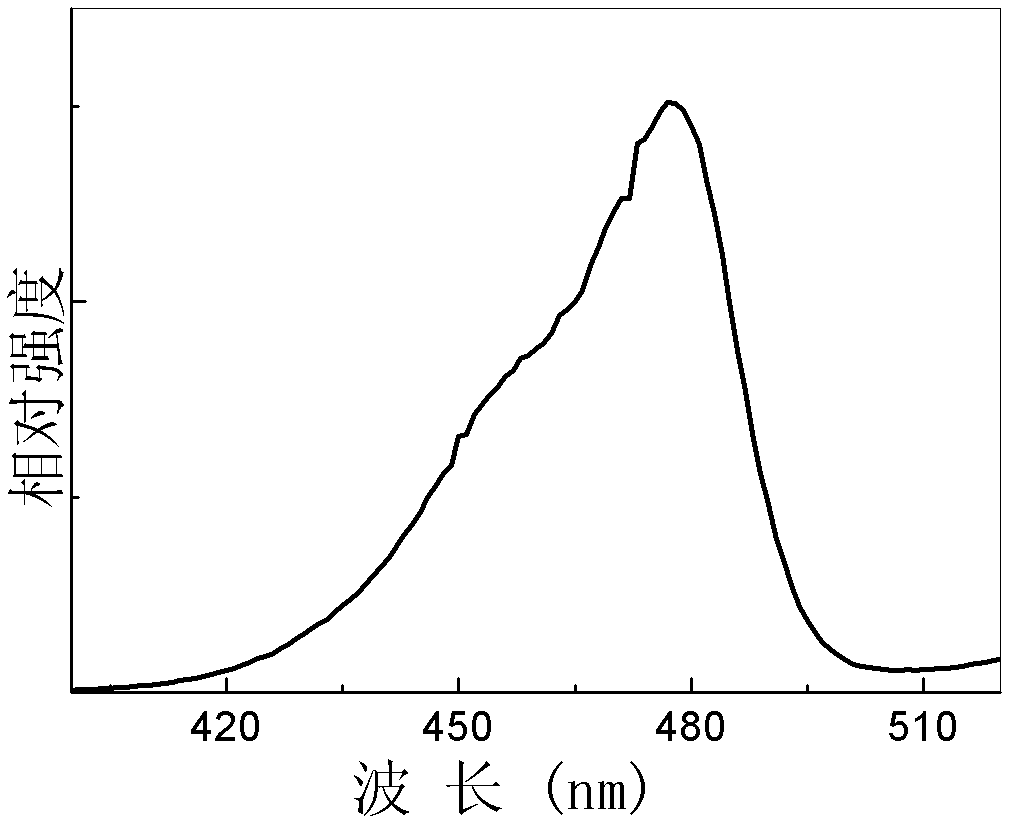

[0034] Select strontium carbonate, boric acid and bismuth trioxide as starting materials, press Sr 0.995 B 4 o 7 : 0.005 Bi take by weighing three kinds of raw materials respectively, and the total weight of the control mixture is 20 grams. After 20 grams of the mixture were mixed by ball milling, they were put into a corundum crucible, and then the crucible was put into a high-temperature electric furnace. Precisely control the heating rate, control the boric acid decomposition reaction speed, prevent the mixture from overflowing from the crucible, the sample is at 500 o C in air for 1 hour. Take out the pre-fired sample, grind and mix it again, put it into a crucible, and heat it under air at 750 o C firing for 10 hours. After grinding, under the air at 850 o C firing for 20 hours. After grinding again, the sample is at 850 o CH 2 Treated in medium for 30 minutes, the divalent bismuth-doped strontium borate was prepared. For comparison, samples with the same compos...

Embodiment 2

[0036] Select strontium bicarbonate, diboron trioxide and bismuth powder as starting materials, press Sr 0.995 B 4 o 7 : 0.005 Bi take by weighing three kinds of raw materials respectively, and the total weight of the control mixture is 20 grams. After 20 grams of the mixture were mixed by ball milling, they were put into a corundum crucible, and then the crucible was put into a high-temperature electric furnace. Precisely control the heating rate, control the boric acid decomposition reaction speed, prevent the mixture from overflowing from the crucible, the sample is at 300 o C pre-fired in air for 5 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, and heat it under air at 750 o C firing for 10 hours. After grinding, under the air at 850 o C firing for 5 hours. After grinding again, the sample is at 850 o C N 2 / H 2 After 60 minutes of medium treatment, bivalent bismuth-doped strontium borate was prepared. For comparison, sampl...

Embodiment 3

[0038] Select strontium oxalate, boric acid and bismuth powder as starting materials, press Sr 0.995 B 4 o 7 : 0.005 Bi take by weighing three kinds of raw materials respectively, and the total weight of the control mixture is 20 grams. After 20 grams of the mixture were mixed by ball milling, they were put into a corundum crucible, and then the crucible was put into a high-temperature electric furnace. Precisely control the heating rate, control the boric acid decomposition reaction speed, prevent the mixture from overflowing from the crucible, the sample is at 400 o C pre-fired in air for 5 hours. Take out the pre-fired sample, grind and mix it again, put it into a crucible, and heat it under air at 750 o C firing for 10 hours. After grinding, under the air at 850 o C firing for 2 hours. After grinding again, the sample is at 850 o Divalent bismuth-doped strontium borate was prepared by treating in C CO for 600 minutes. For comparison, samples with the same composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com