Continuous annealing unit and circulating temperature control device for aging section of continuous annealing unit

A technology of cyclic temperature control and continuous withdrawal unit, which is used in the improvement of process efficiency, heat treatment process control, furnace type and other directions, can solve the problems of prolongation, furnace thermal inertia fluctuation, environmental pollution, etc. The temperature control is fast and effective, and the effect of improving the reflection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

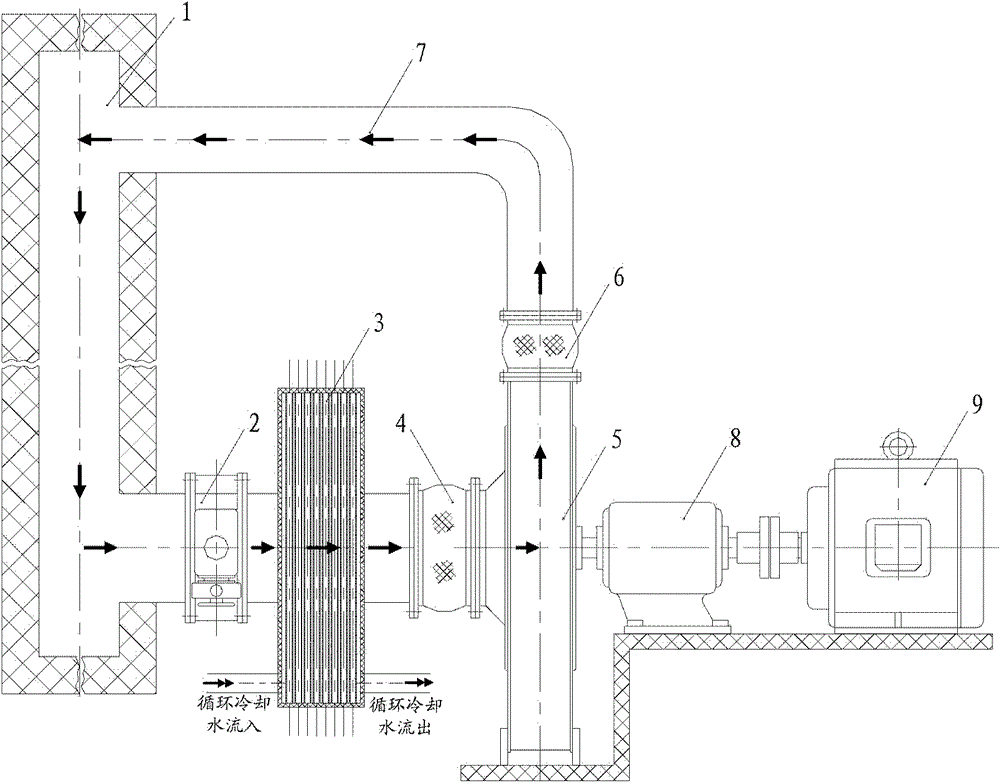

[0021] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. The present invention utilizes the mode of absorbing the hot gas medium from the bottom of the furnace in the aging section, and then injecting the cold gas medium into the top of the furnace in the aging section, making full use of the sinking characteristics of the cold gas medium, and rapidly making the atmosphere temperature in the furnace in the aging section reach the required level temperature conditions.

[0022] figure 1 It is a schematic diagram of the circulation temperature control device of the aging section of the continuous annealing unit according to an exemplary embodiment of the present invention, and the arrows in the figure indicate the flow direction. According to the circulation temperature control device of the aging section of the continuous annealing unit of the present invention, it includes a pipeline 7, a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com