Production equipment of compound non-woven fabric absorber, process and compound non-woven fabric absorber

A kind of production equipment and non-woven fabric technology, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problem of the decline in the performance of composite non-woven fabric absorbers, affecting the softness and water absorption properties of composite non-woven fabric absorbers, and affecting the composite non-woven fabric absorbers. Non-woven absorbent body handle and other problems, to achieve the effect of improving water absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

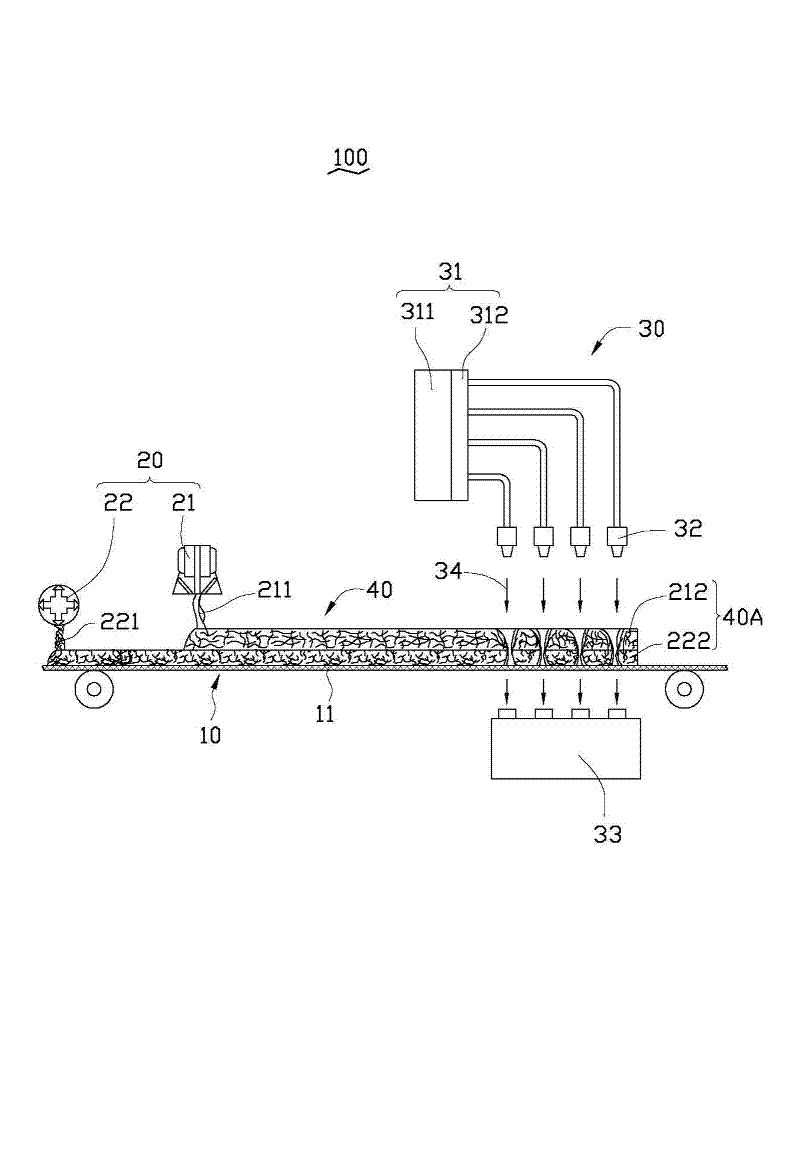

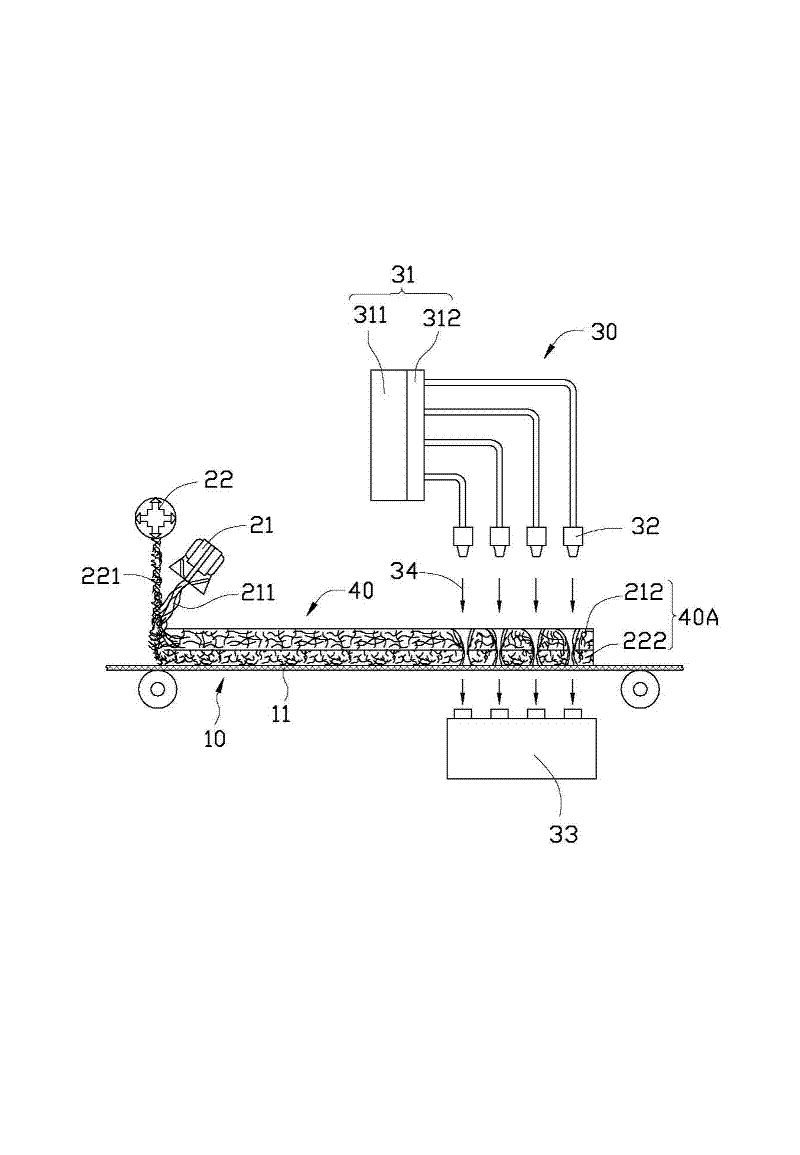

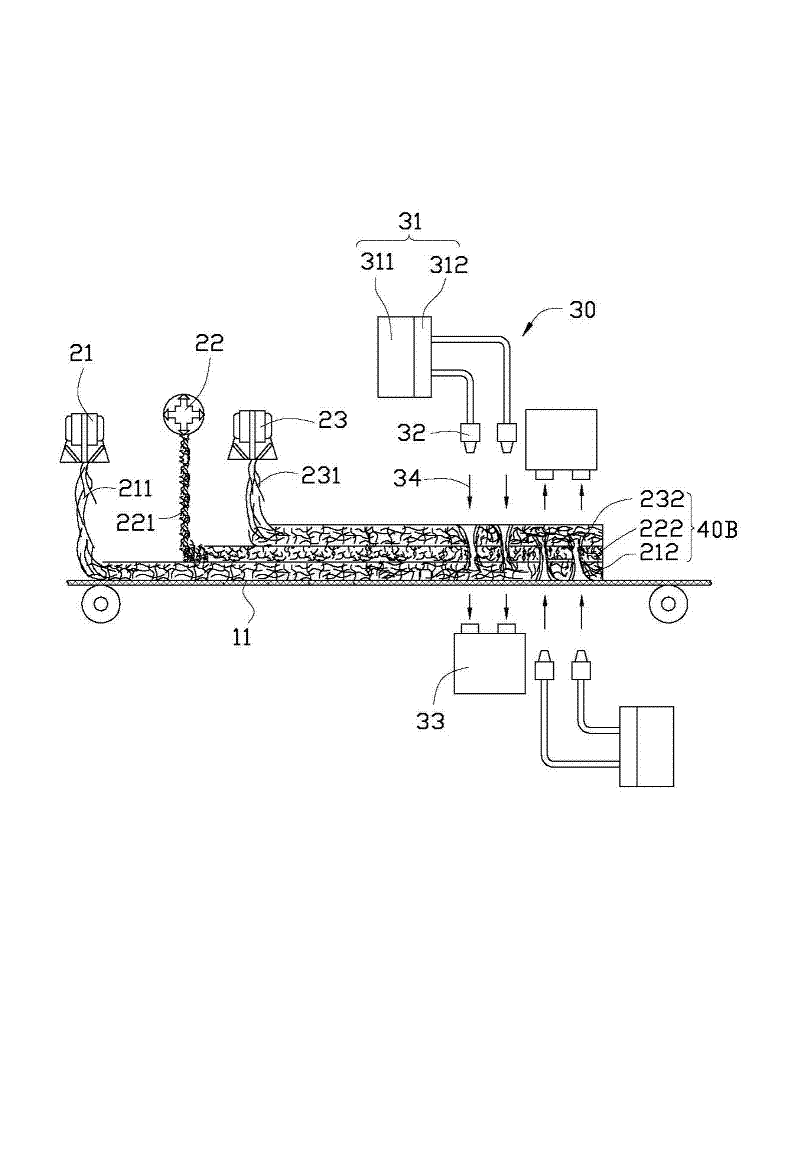

[0022] See figure 1 As shown, the composite non-woven absorbent body production equipment 100 provided by the embodiment of the present invention includes a transmission unit 10, a meshing unit 20, and a consolidation unit 30.

[0023] The conveying unit 10 includes a supporting net 11, and the conveying unit 10 is used to convey the fiber composite formed on the supporting net 11 to each section of the composite non-woven absorbent body production equipment 100 for the The fiber composite is processed.

[0024] The mesh laying unit 20 is used for laying a non-woven fiber composite body 40 on the supporting mesh curtain 11.

[0025] In this embodiment, the laying unit 20 includes a first hot-melt fiber laying machine 21 and a hydrophilic fiber laying machine 22, wherein the first hot-melting fiber laying machine 21 is used to output the first The hot-melt fiber stream 211 is used to form the first hot-melt fiber layer 212, and the hydrophilic fiber laminator 22 is used to output the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com