Novel sealing bowl-shaped plug for highly intensified diesel engine

A diesel engine and sealing bowl technology, which is applied to the sealing device of the engine, mechanical equipment, engine components, etc., can solve the problems of sealing failure, cost increase, installation creases and pits, etc., to reduce the stress concentration of the fillet and reduce the cost , the effect of high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

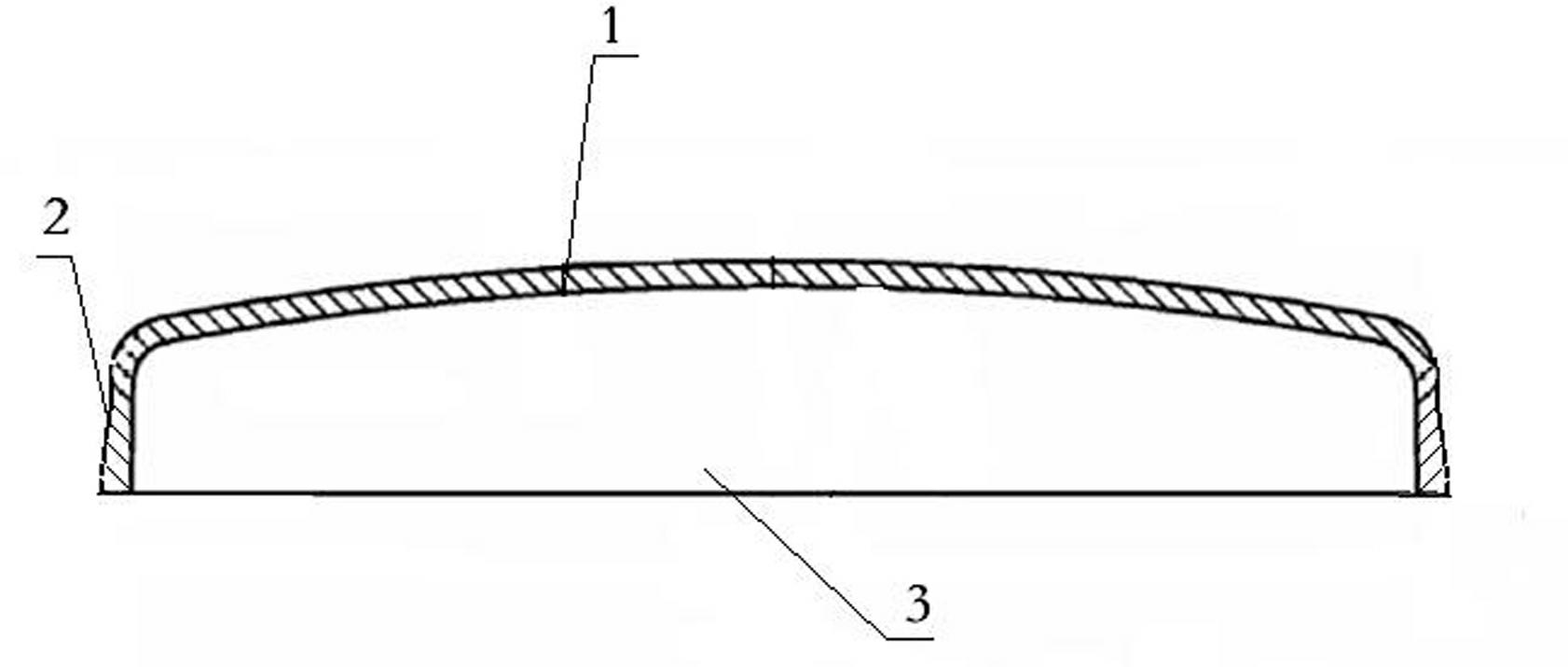

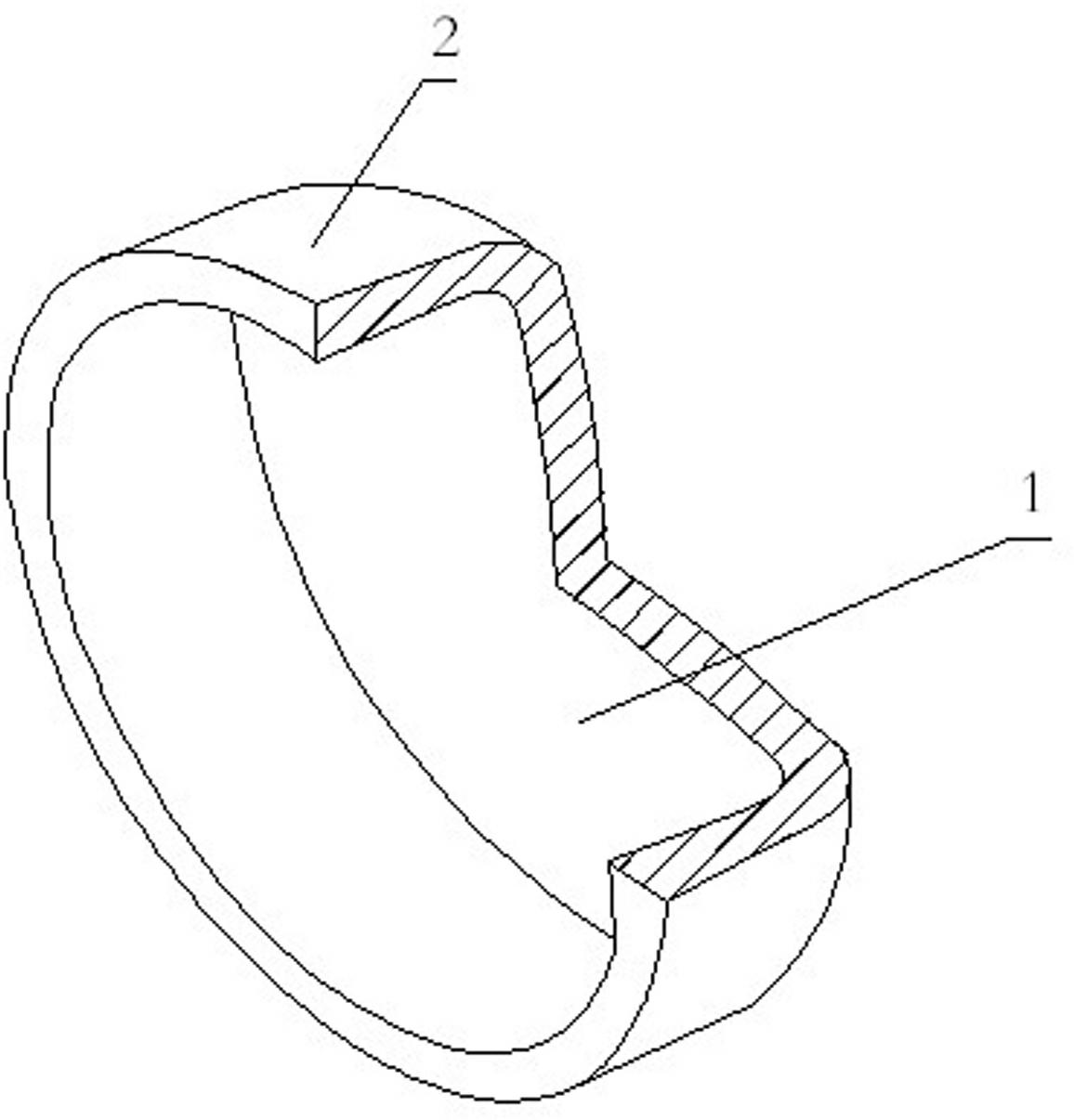

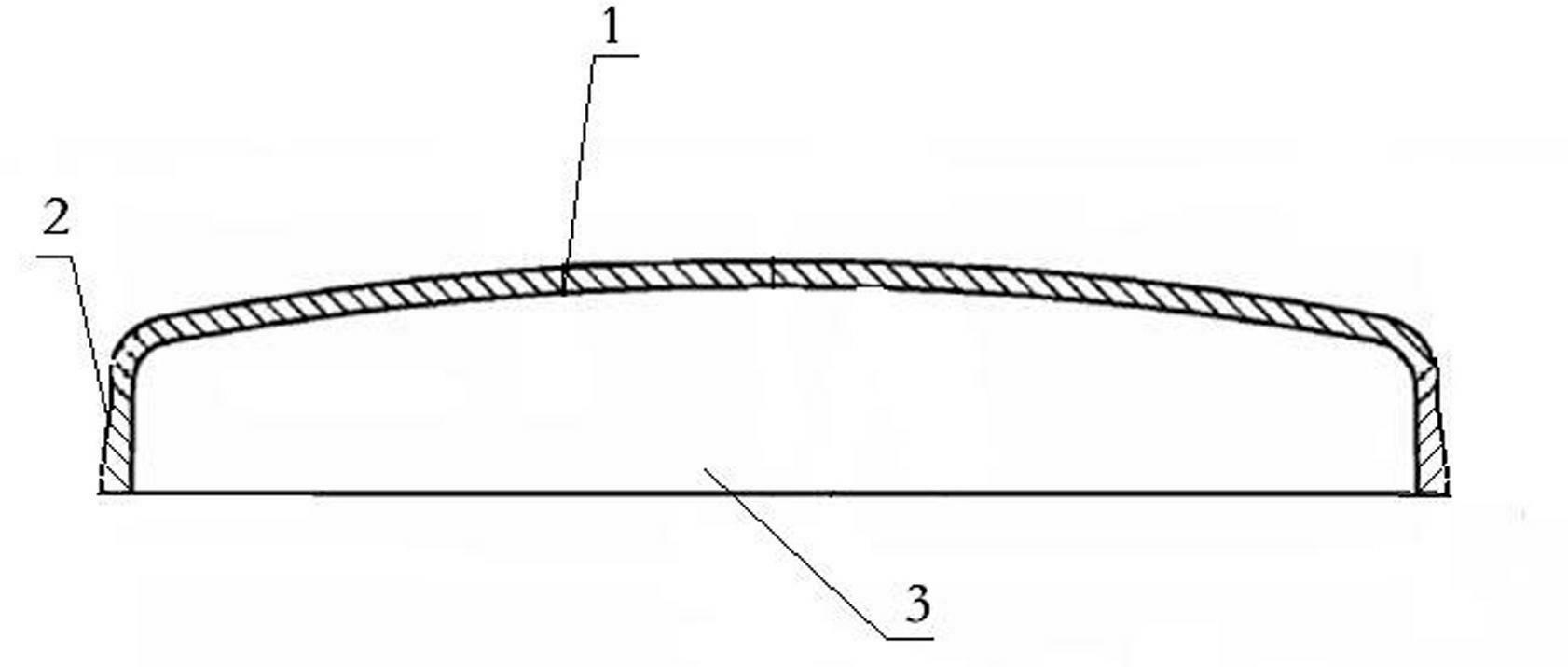

[0018] Such as figure 1 , 2 Shown, a kind of novel sealing bowl type plug that a kind of highly strengthened diesel engine of the present invention uses, comprises

[0019] Including the plug body, the top of the plug body is a circular end face 1, the edge of the end face 1 extends downwards with an annular side wall 2, the bottom of the plug body is a circular plug opening 3, and the plug body is made of stainless steel. Bowl-shaped plugs made of stainless steel are resistant to corrosion, high in rigidity, and strong in resistance to plastic deformation under working conditions. Larger interference can be used to increase the sealing effect. The temperature at the center of the bowl-shaped plug made of stainless steel is reduced by about 15 degrees Celsius. At the same time, the fatigue strength of the stainless steel structure is increased, and the cost is lower.

[0020] The cross section of the side wall 2 of the plug body is tapered with a narrow top and a wide bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com