Method for accurately and quantitatively analyzing combustion residue of boron-based fuel-rich propellant

A technology for quantitative analysis of combustion residues, applied in chemical analysis by titration method, analysis by making materials undergo chemical reactions, and material analysis by observing the impact on chemical indicators, etc., can solve the problem of low boric acid residue Problems such as result errors and small titration results can achieve the effect of comprehensive analysis, small errors and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

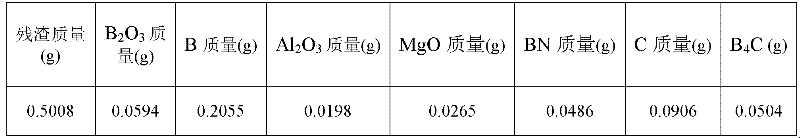

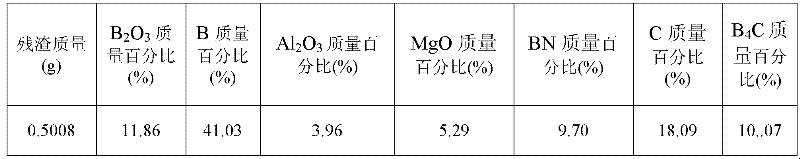

[0029] 1. Weigh 0.5008g of the residue and place it in a 250ml ground-mouth bottle, add 50ml of distilled water, and carry out ultrasonic dispersion at 50°C for 30min to obtain a solution. Add 10ml of 2mol / L dilute hydrochloric acid (density of 1.03g / cm 3), then adjust the solution after adding dilute hydrochloric acid to pH=5 with 1mol / L standard sodium hydroxide solution, adopt medium-speed filter paper to filter, add 7.5g mannitol to promote the dissociation of boric acid in the filtered filtrate, use 1mol / L standard sodium hydroxide solution and titrate the solution obtained after adding mannitol to pH=7.

[0030] 2. Add 50ml of distilled water to the filter residue filtered by medium-speed filter paper in the first step, and then add 50ml of 10% H 2 o 2 and 1.5gK 2 S 2 o 8 Boil and reflux for 30 minutes. After the boiled and refluxed solution is cooled to room temperature, add 7.5 g of mannitol to promote the dissociation of boric acid, and then use standard sodium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com