Environment control system of lithographic equipment

A lithography equipment and control system technology, applied in the field of lithography equipment environment control system, can solve problems such as large volume, uneven temperature, complex system structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

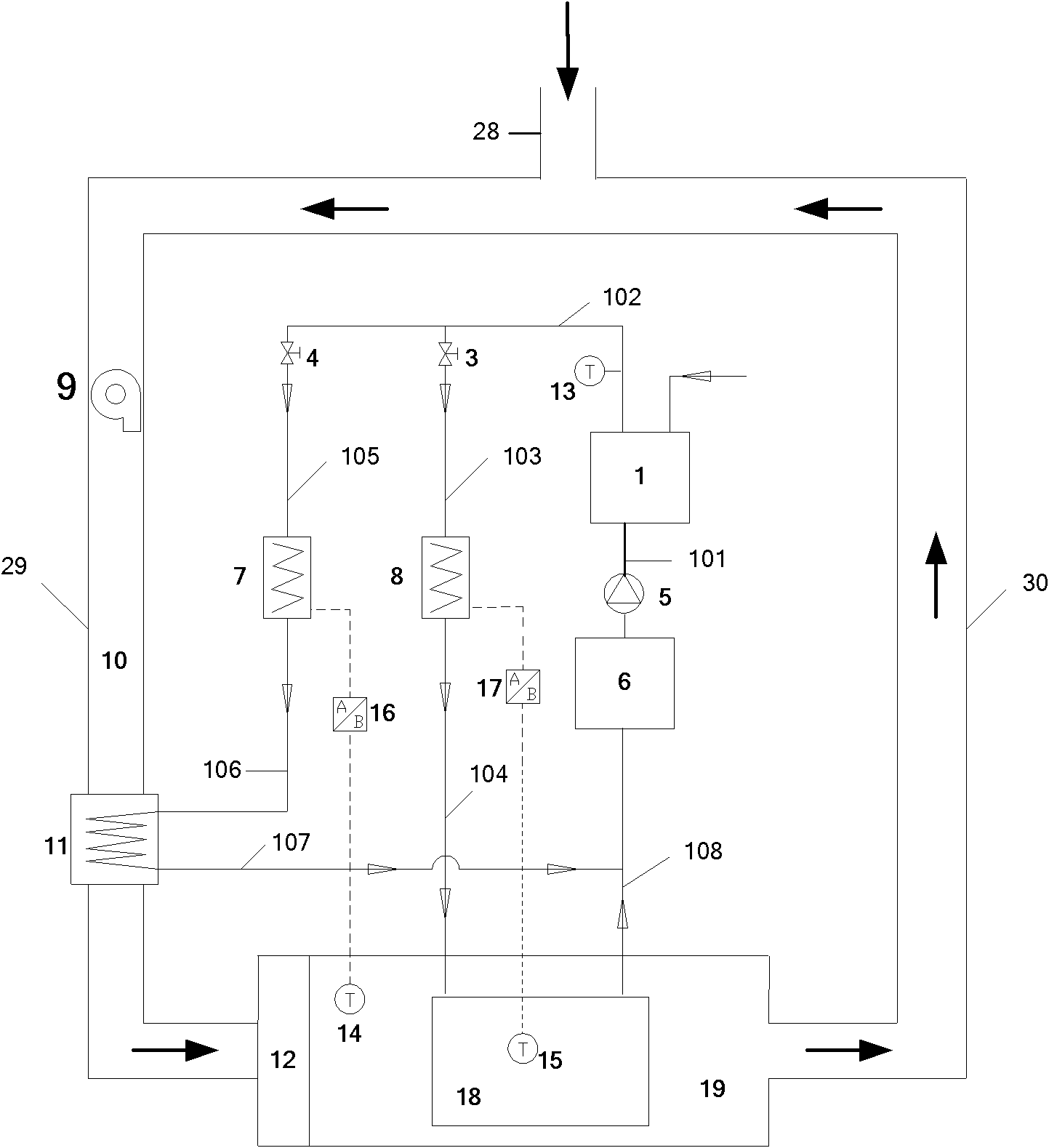

Embodiment 1

[0031] Such as figure 2 As shown, the lithography equipment environment control system of the present invention includes a controlled unit, which is a controlled object; a cooling water delivery unit that provides a cooling water source and outputs the cooling water; a temperature control unit that outputs the cooling water source from the cooling water delivery unit After temperature adjustment, to control the temperature of the controlled unit; the air delivery unit is used to deliver air to the controlled unit.

[0032] The controlled unit includes a lithography apparatus, and the lithography apparatus includes a cavity 19 and an objective lens 18 installed in the cavity 19, and the water outlet of the objective lens 18 passes through the eighth cooling water pipe 108 and the cooling water delivery unit pipe. road connection.

[0033] A static pressure chamber 12 is provided at the air inlet of the cavity 19 .

[0034] The cooling water delivery unit includes a water tan...

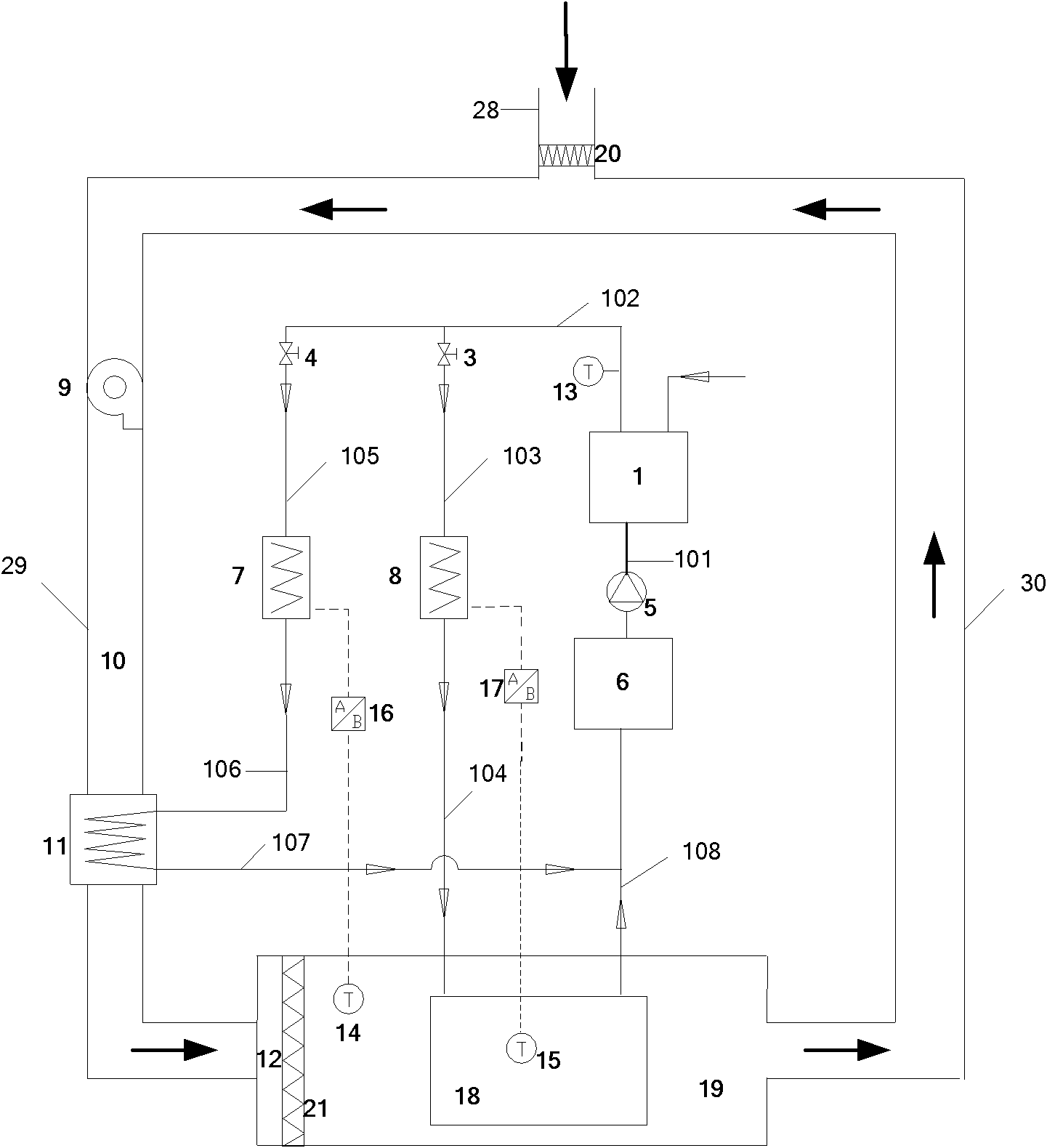

Embodiment 2

[0039] Such as image 3 As shown, this embodiment is improved on the basis of Embodiment 1, and the difference is that a primary filter 20 is installed in the air inlet 28 of the ventilation duct 10 . A high efficiency filter 21 is installed in the static pressure chamber 12 of the controlled unit.

Embodiment 3

[0041] Such as Figure 4 As shown, this embodiment is improved on the basis of Embodiment 2, and the difference is: a humidifier 22 is also installed on the air inlet duct 29 of the ventilation duct 10 of the air delivery unit, and the humidifier 22 passes through The third PID controller 24 is electrically connected with the humidity sensor 25, and the humidity sensor 25 is installed in the cavity 19 of the controlled unit. The third heater 23 is installed on the air inlet duct 29 of the ventilation duct 10 of the air delivery unit, the third heater 23 is electrically connected with the fourth temperature sensor 27 by the fourth PID controller 26, and the fourth temperature sensor 27 is installed on In the cavity 19 of the controlled unit.

[0042] The working principle of the present invention is as follows: the water pump 5 extracts water from the water tank 6, and delivers it to the refrigerator 1 through the first cooling water pipe 101, sets a temperature value for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com