Manufacture method of nano point array with perpendicular magnetic anisotropy

An anisotropic, perpendicular magnetic technology, used in the manufacture of record carriers, etc., can solve the problems of film damage, deterioration of perpendicular magnetic anisotropy, damage to the edge of nano-dots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

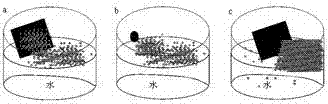

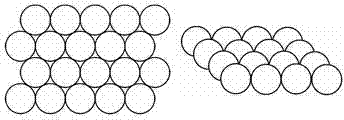

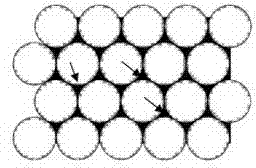

[0021] First, a single-layer hexagonal close-packed colloidal array spherical substrate was prepared by self-assembly technology. figure 1 Middle a. Spread the colloidal spheres on the water surface; b. Make the spheres monolayer close together to form an ordered monolayer film; c. Transfer the ordered monolayer film to the substrate. The formed single-layer colloidal array is a hexagonal close-packed structure (as attached figure 2 shown).

[0022] The specific steps are: immerse the silicon substrate in 10% sodium dodecyl sulfate solution for 24 hours to obtain a hydrophilic substrate surface. Take 5 milliliters of 10wt.% polystyrene colloidal solution, dilute it with 5 milliliters of ethanol, and then take about 5 microliters and drop it on the surface of the soaked substrate, and the solvent and the beads spread on the surface of the substrate. The substrate piece is slowly immersed in a container containing deionized water, the container has a cross-sectional area of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com