A double-layer perovskite manganese oxide single-phase film material with vertically aligned nanostructures and its preparation method

A technology of double-layer perovskite and manganese oxide, which is applied in the direction of manganese compounds, chemical instruments and methods, nanotechnology, etc., can solve the problems such as difficult to obtain nanostructure growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The specific steps of preparation are as follows:

[0028] S1, according to the chemical formula La 1-x Ca x MnO 3 Select x=0.5, that is, the chemical formula of the material is La 0.5 Ca 0.5 MnO 3 According to the molar ratio of lanthanum, calcium, and manganese, weigh lanthanum oxide, calcium oxide, and manganese oxide respectively, grind them evenly with an agate bowl, and then sinter at high temperature for many times to form lanthanum calcium manganese oxide powder. Finally, it is sintered at high temperature through mold pressing to form La 0.5 Ca 0.5 MnO 3 target.

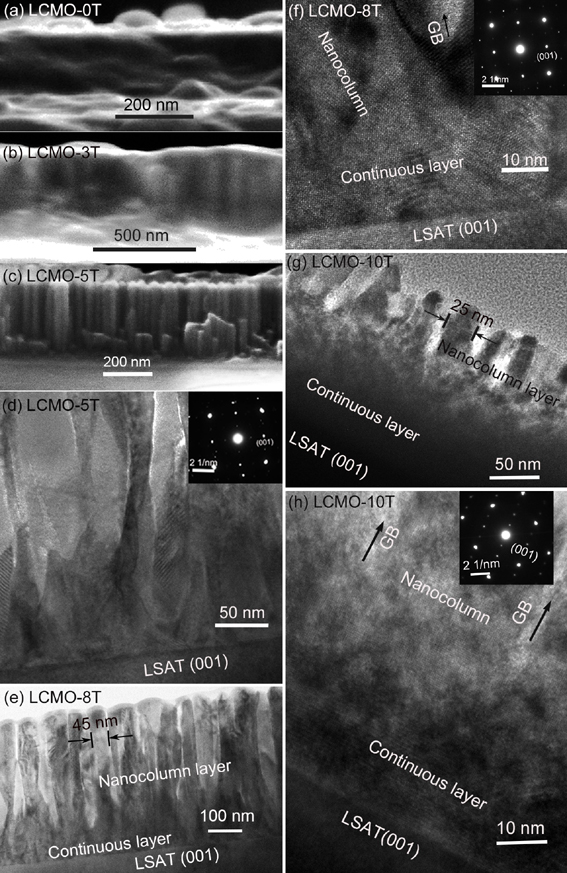

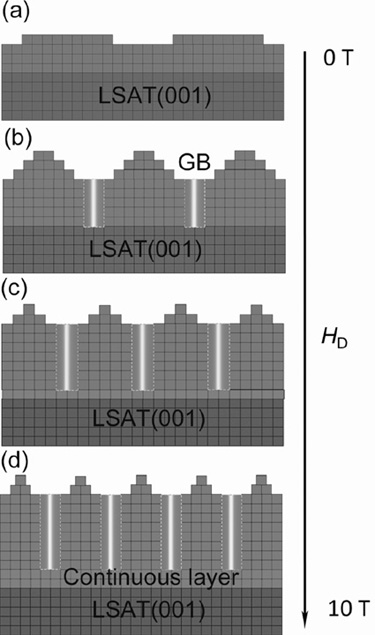

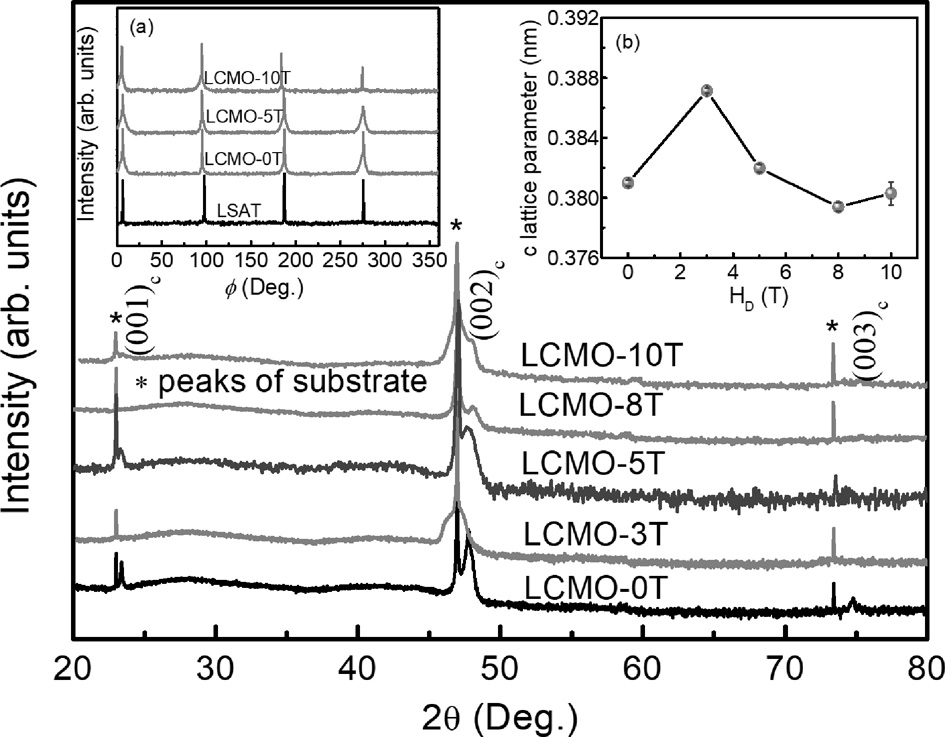

[0029] S2, select (LaAlO 3 ) 0.3 (Sr 2 AlTaO 6 ) 0.7 (001)[LSAT(001)] single crystal substrate. First, the substrate and the La prepared in S1 0.5 Ca 0.5 MnO 3 The target is mounted in a pulsed laser deposition system and the chamber is then evacuated. The substrate was first heated to 680 °C before the thin film was prepared. Then a superconducting magnet is used to apply a strong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com