Preparation method of high-nickel ternary lithium ion battery positive electrode material and product thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of high-nickel ternary lithium-ion battery positive electrode materials, can solve the problems of the first discharge specific capacity and the first charge and discharge efficiency decline, and achieve the improvement of comprehensive electrochemical performance and good battery life. Effect of chemical properties and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

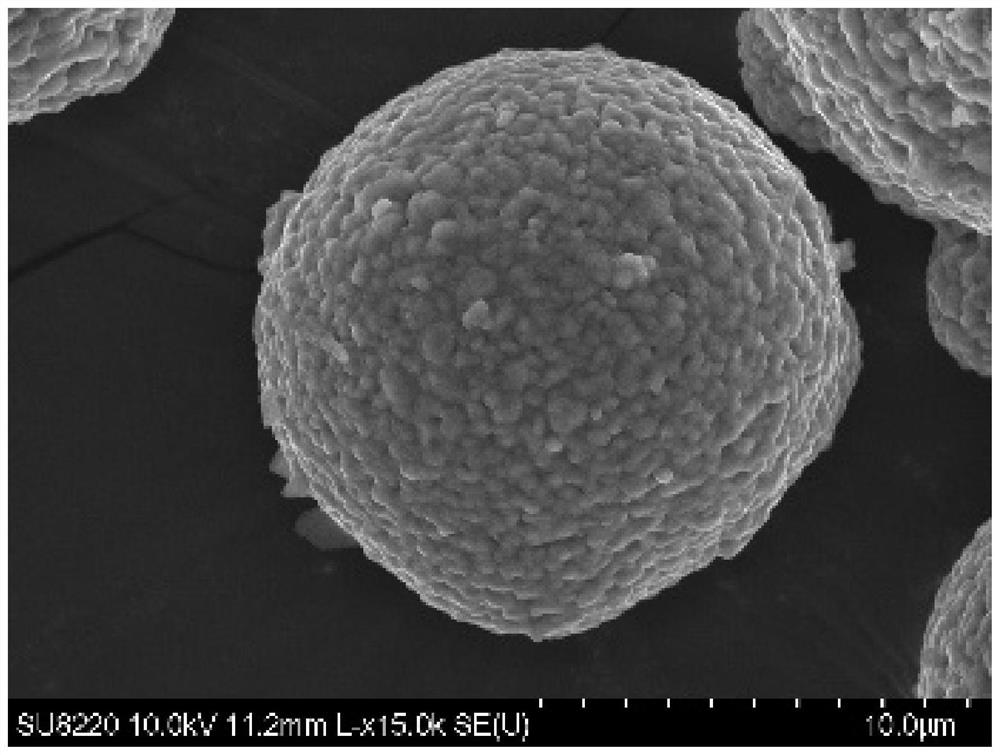

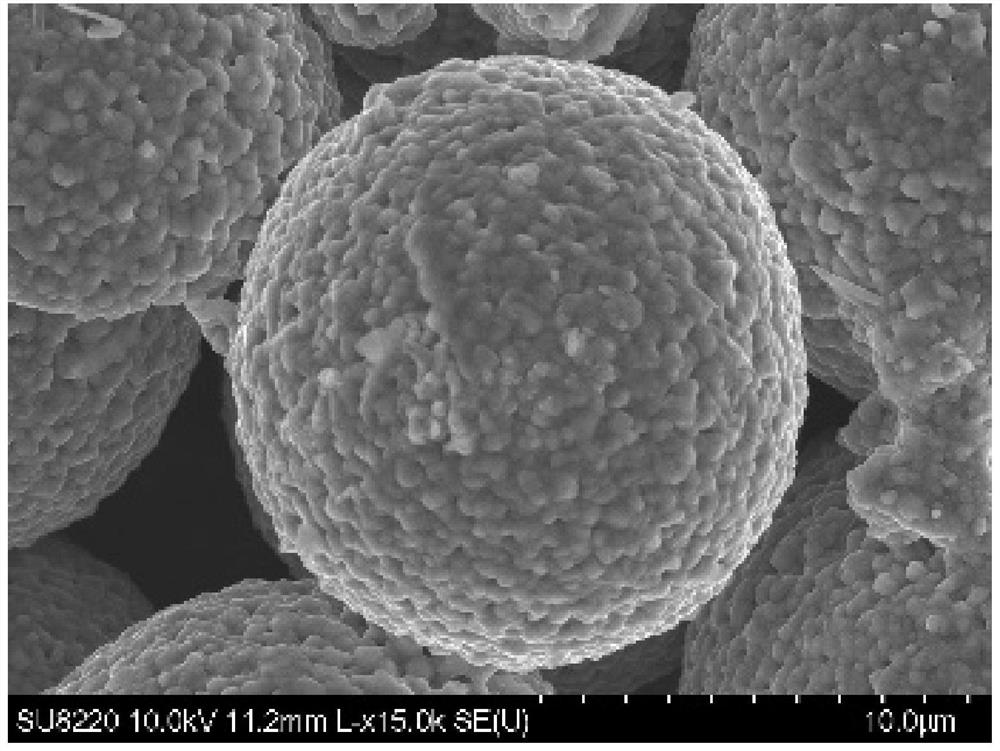

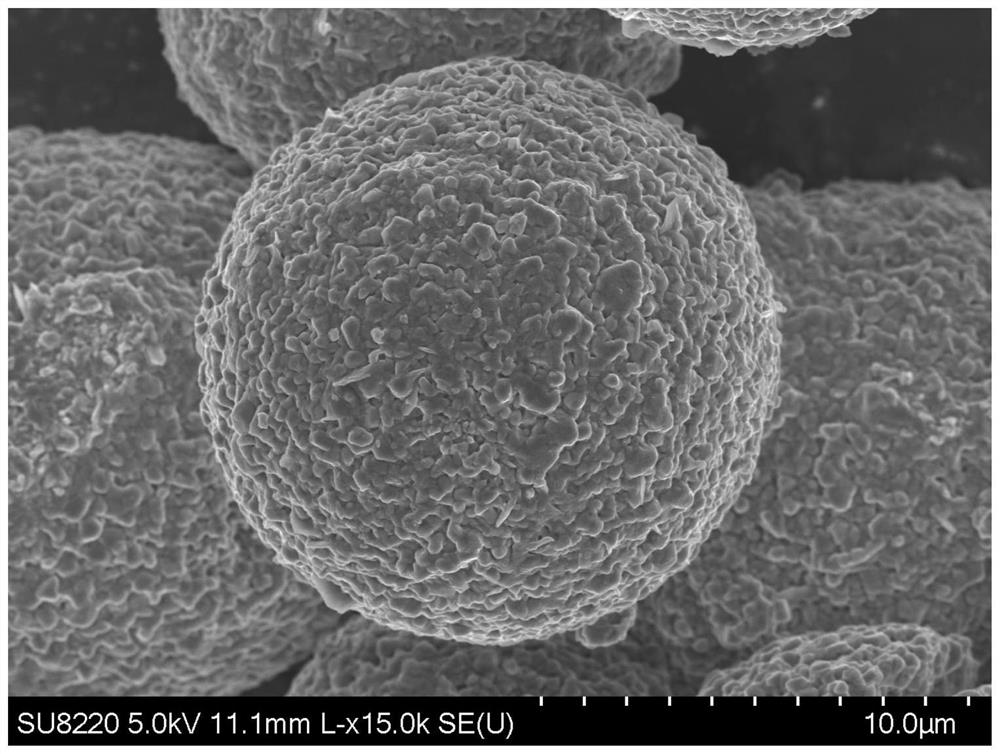

Image

Examples

Embodiment 1

[0068] S11, 4.20g of isopropanol aluminum (purity 99.99%), 1.61g of isopropoxyzirconium isopropanol complex dissolved in 50ml of absolute ethanol, room temperature magnetic stirrer at 1300 rpm stirring for 1.5h, to obtain a composite salt solution;

[0069] S12, the compound salt solution was added to 36.19gNi 0.93 Co 0.07 (OH) 2 In the powder, after magnetic stirring for 0.5h, the slurry A is obtained;

[0070] S13, preparation of ethanol aqueous solution: deionized water and absolute ethanol according to the volume ratio of 1:2 mixed uniformly, to obtain an aqueous ethanol solution;

[0071] S14, in step S12 obtained slurry A added 60mL of ethanol aqueous solution, after magnetic stirring 0.5h, heating to 60 °C, stirring at 1000rpm speed for 1.5h, room temperature aging 24h, filtering, drying at 80 °C in the drying box for 24h, to obtain a ternary precursor.

[0072] S15: Take 18.98g ternary precursor and 9.23g LiOH· H 2 O is evenly mixed, where Li: (Ni + Co + Al) = 1.05:1 (mola...

Embodiment 2

[0074] S11, 4.17g of isopropanol aluminum (purity 99.99%), 2.41g of isopropoxyzirconium isopropanol complex dissolved in 50ml of absolute ethanol, room temperature magnetic stirrer at 1300rpm stirring for 1.5h, to obtain a composite salt solution;

[0075] S12, the composite salt solution was added to 35.94gNi 0.93 Co 0.07 (OH) 2In the powder, after magnetic stirring for 0.5h, the slurry A is obtained;

[0076] S13, preparation of ethanol aqueous solution: deionized water and absolute ethanol according to the volume ratio of 1:2 mixed uniformly, to obtain an aqueous ethanol solution;

[0077] S14, in step S12 obtained slurry A added 60mL of ethanol aqueous solution, after magnetic stirring 0.5h, heating to 60 °C, stirring at 1000rpm speed for 1.5h, room temperature aging 24h, filtering, drying at 80 °C in the drying box for 24h, to obtain a ternary precursor.

[0078] S15: Take 18.98g ternary precursor and 9.22g LiOH· H 2 O is evenly mixed, where Li: (Ni + Co + Al) = 1.05:1 (molar...

Embodiment 3

[0080] S11, 4.14g of isopropanol aluminum (purity 99.99%), 3.21g of isopropoxyzirconium isopropanol complex dissolved in 50ml of absolute ethanol, room temperature magnetic stirrer at 1300 rpm stirring for 1.5h, to obtain a composite salt solution;

[0081] S12, the composite salt solution was added to 35.69gNi 0.93 Co 0.07 (OH) 2 In the powder, after magnetic stirring for 0.5h, the slurry A is obtained;

[0082] S13, preparation of ethanol aqueous solution: deionized water and absolute ethanol according to the volume ratio of 1:2 mixed uniformly, to obtain an aqueous ethanol solution;

[0083] S14, in step S12 obtained slurry A added 60mL of ethanol aqueous solution, after magnetic stirring 0.5h, heating to 60 °C, stirring at 1000rpm speed for 1.5h, room temperature aging 24h, filtering, drying at 80 °C in the drying box for 24h, to obtain a ternary precursor.

[0084] S15: Take 18.98g ternary precursor and 9.20g LiOH· H2 O is evenly mixed, where Li: (Ni + Co + Al) = 1.05:1 (mola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com