Production method of nitrogen-free dielectric antireflective film

A production method and anti-reflection technology, applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problem of poor photoresist shape, inability to effectively eliminate photoresist standing wave effect and photoresist poisoning effect, and difficult to control Nitrogen-free dielectric anti-reflection film reflectivity extinction coefficient and other issues, to achieve the effect of controlling reflectivity and extinction coefficient, eliminating standing wave effect of photoresist, and eliminating poisoning effect of photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

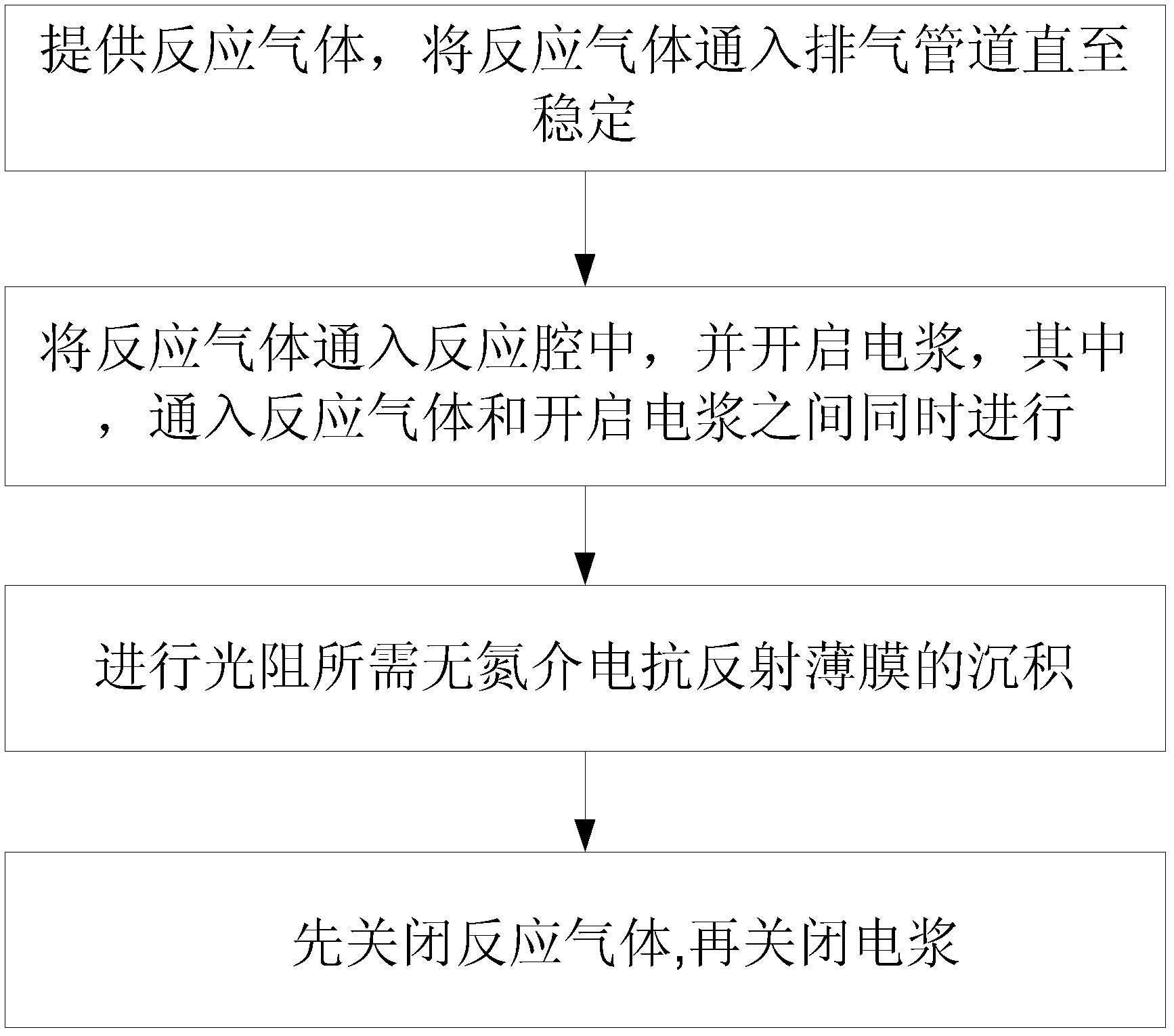

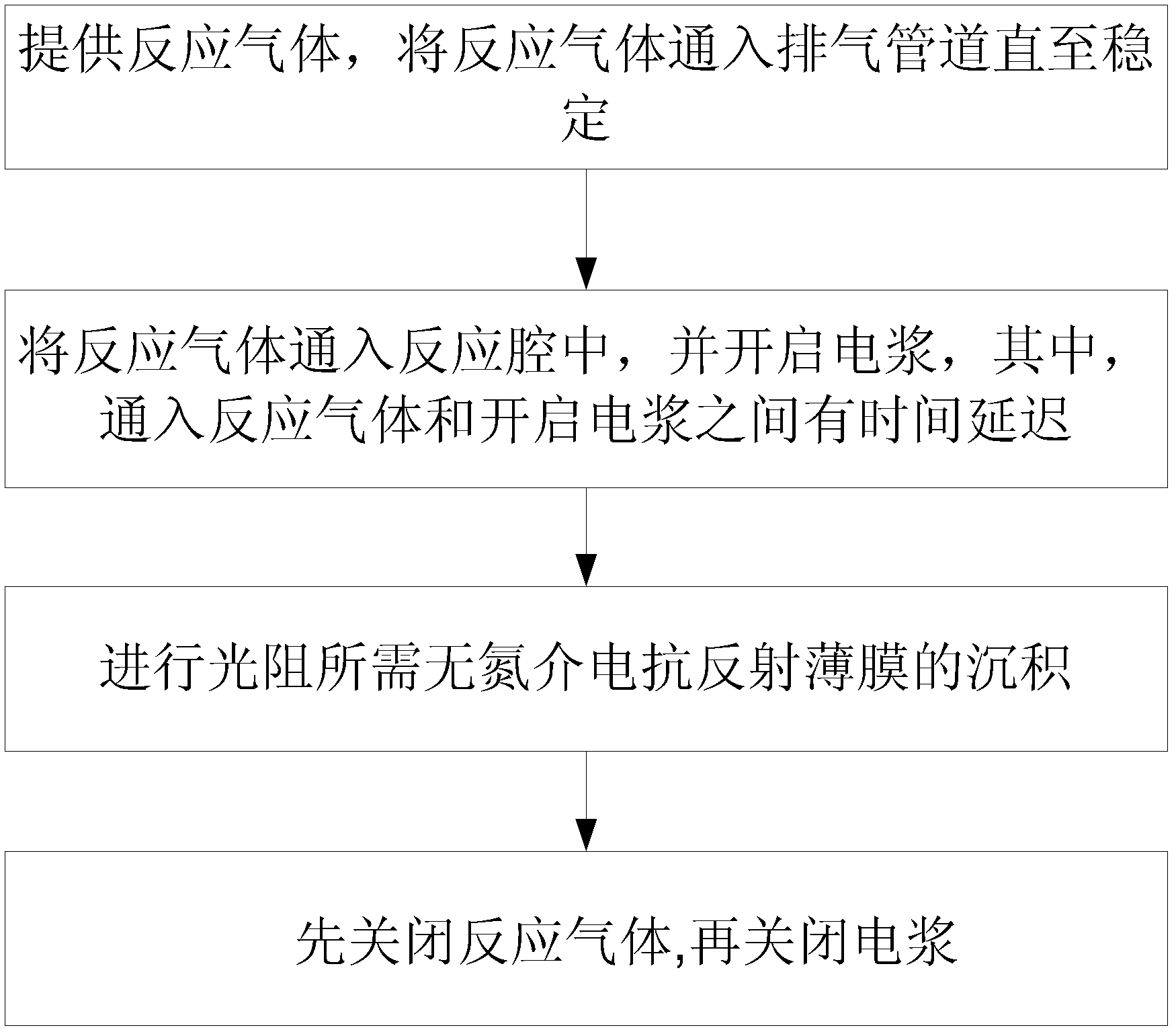

[0021] Such as figure 2 Shown, the manufacture method of the nitrogen-free dielectric antireflective film of an embodiment of the present invention, comprises the steps:

[0022] Firstly, a reactive gas is provided, which is a mixed gas of silane and carbon dioxide, and helium or other inert gas can also be used as an auxiliary gas.

[0023] Next, the above-mentioned reaction gas is passed into the exhaust pipe, and the flow rate of the reaction gas is kept stable;

[0024] Next, the above-mentioned reaction gas is passed into the reaction chamber, and the plasma is turned on. There is a certain time delay between passing the reaction gas and turning on the plasma. Preferably, the time delay is between 0.1 second and 2 seconds. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com