High-power composite piezoelectric transducer

A piezoelectric transducer, high-power technology, used in piezoelectric/electrostrictive transducers, sensors, electrical components, etc., can solve problems such as clogging of sandstone formations, reduced crude oil production, etc., and achieve increased radial displacement. , increased transmit power, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

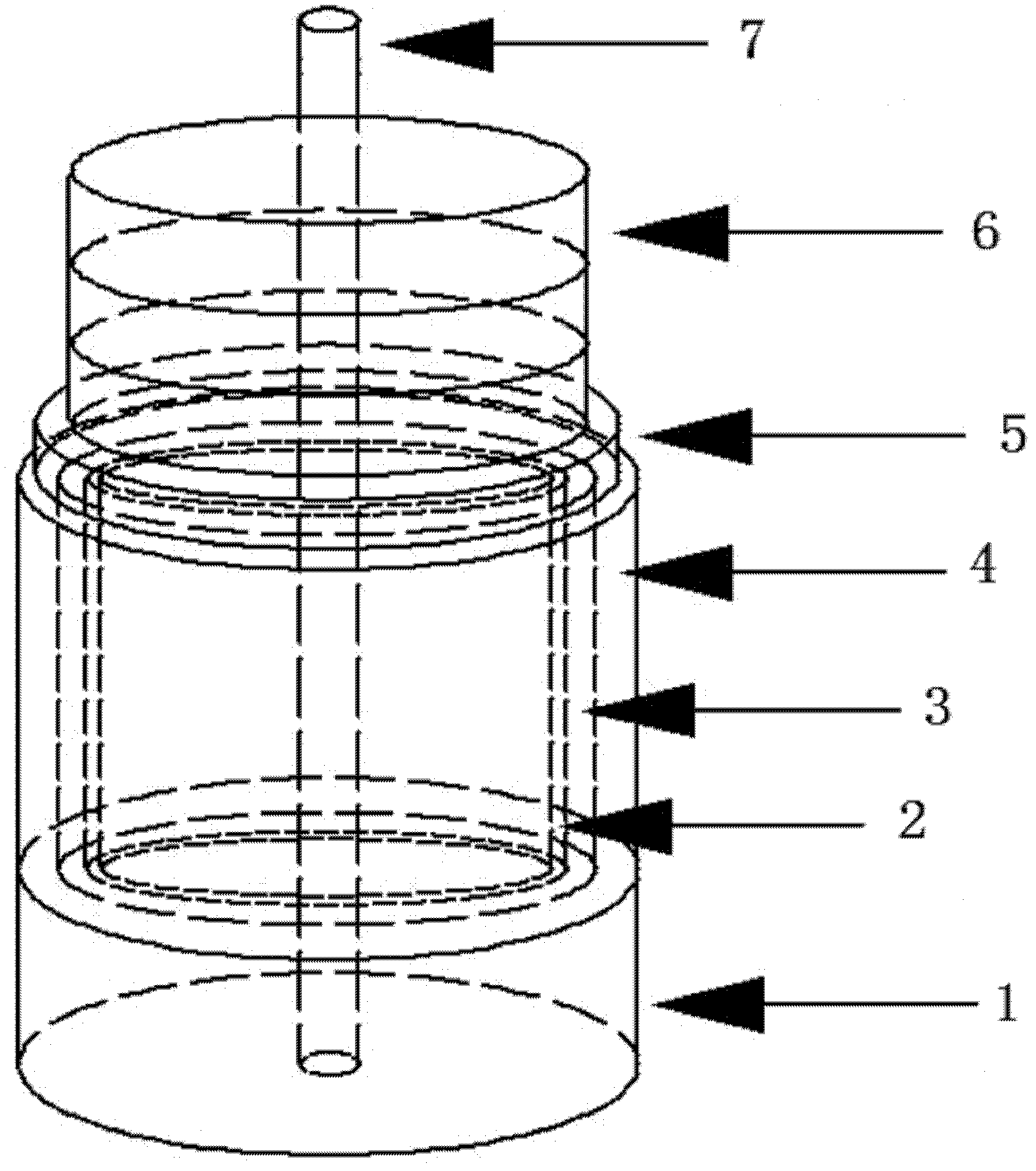

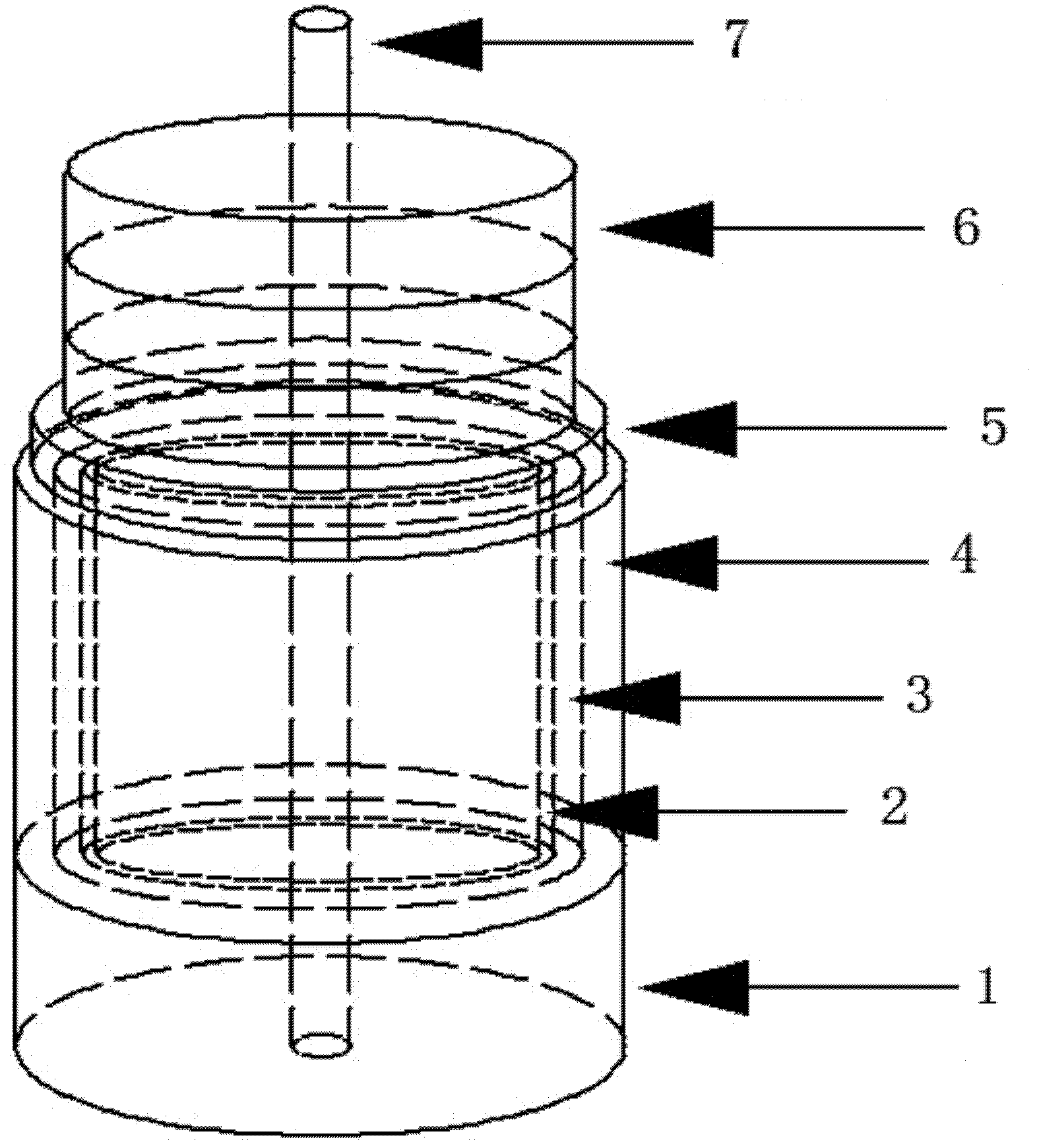

[0015] The high-power composite piezoelectric transducer of the present invention will be described in detail below with reference to the embodiments and drawings.

[0016] The vibrational modes of the long thin aluminum sleeve are the key factors for exciting the energy of the transducer. When the thin aluminum casing vibrates, there are both radial displacement and longitudinal displacement, and the two are coupled to each other. Using this coupling relationship, we can further increase the excitation energy of the transducer. That is to add prestress in the longitudinal direction of the thin aluminum casing, so that the thin aluminum casing is more likely to be excited to vibrate. In order to increase the longitudinal vibration displacement, we also increase the crystal pile in the longitudinal direction to make it vibrate with the thin aluminum casing. In this way, while the longitudinal vibration displacement of the thin aluminum sleeve is further increased, the displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com