Pressure wave pulverizer for gasificatin applications

A pulverizer, pressure wave technology, applied in the direction of furnace, furnace type, hearth type furnace, etc., can solve the problems of pollutant discharge and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

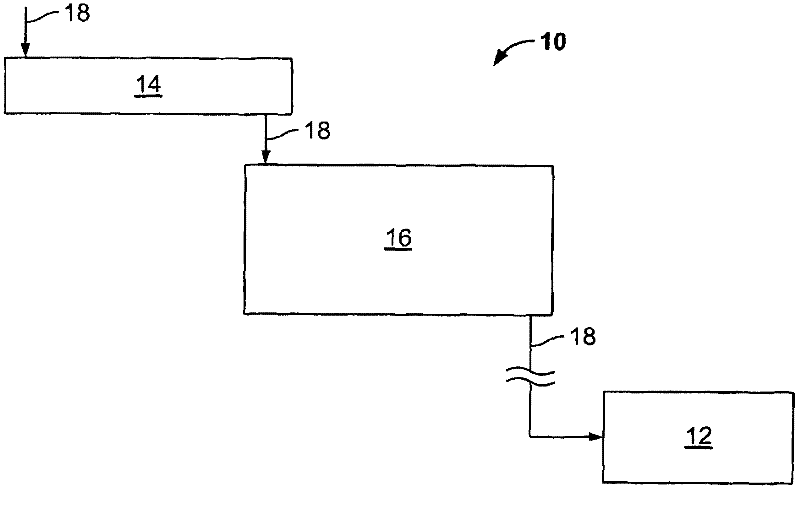

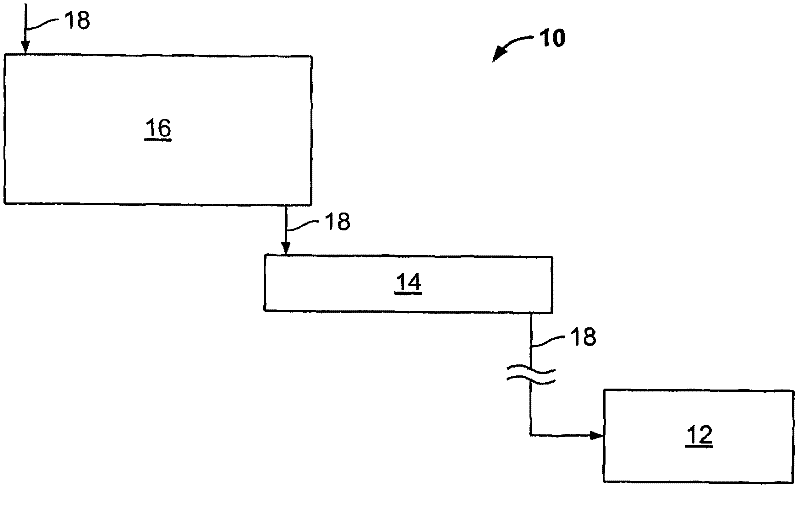

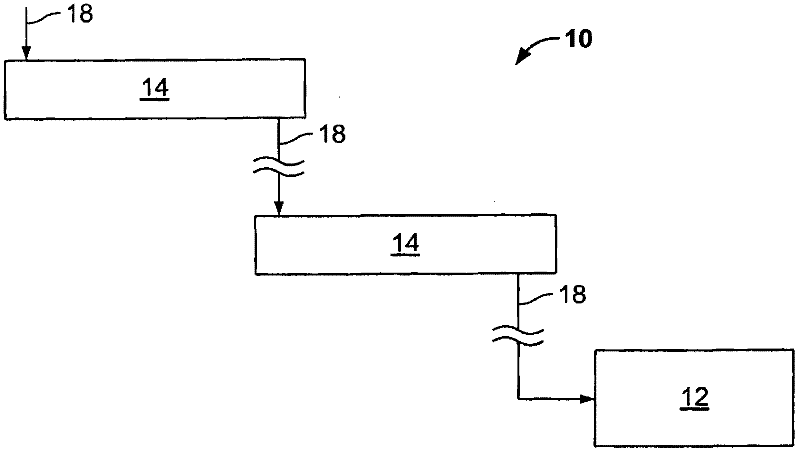

[0060] Examples of embodiments incorporating one or more aspects of the invention are described and shown in the drawings. These illustrated examples are not intended to be limiting of the invention. For example, one or more aspects of the invention may be utilized in other embodiments and even other types of devices.

[0061] The present disclosure relates to gasification applications involving the conversion of carbonaceous materials, such as coal, petroleum, biofuels or biomass, to carbon monoxide and hydrogen by reacting raw materials with controlled amounts of oxygen and / or steam at high temperatures. The resulting gas mixture is a type of fuel known as synthesis gas or syngas, which can include varying amounts of carbon monoxide, methane and hydrogen. A carbonaceous substance refers to a substance consisting of, containing, or capable of producing carbon.

[0062] An exemplary integrated gasification combined cycle (IGCC) system may include a main air compressor, an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com