Method for cleaning drum in production process of cellulose ester thin film

A production process, cellulose ester technology, applied in the field of drum cleaning in the production of cellulose ester film, can solve the problems of deterioration of plasticizer condensation on the drum surface, change of product thickness uniformity, and exacerbation of plasticizer precipitation, etc. Achieve the effects of protection from damage, improvement of film quality, and prevention of micro-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

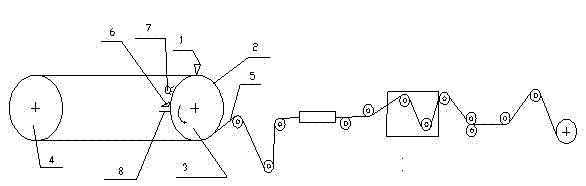

[0037] In the present invention, cellulose triacetate is used as a film-forming material to prepare cotton gum solution, and the addition ratio of plasticizer in the solution is 17% of the weight of cellulose triacetate. A liquid film 5 is formed on the endless cast steel strip 2, and the liquid film 5 is peeled off from the endless cast steel strip 2 after drying, then stretched, dried and finally wound on the winding roller. In order to meet the needs of production, The production speed is 15 m / min.

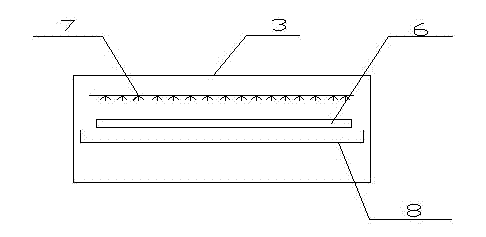

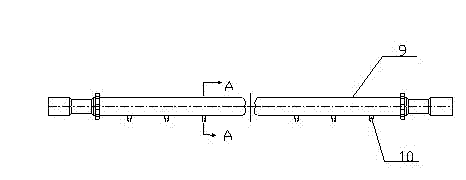

[0038] In the film production process, in order to thoroughly clean the foreign matter on the surface of the front drum, a spray device 7 is installed 5 cm above the drum scraper 6 on the front drum 3, and the angle between the nozzle 10 and the drum surface of the front drum 3 is adjusted to make the wet surface width of the spray liquid The control spray volume is 1L / min, the spray pressure is 1.5bar, the solvent used is a mixed solution of dichloromethane and methanol (volum...

Embodiment 2

[0040] The film production process is the same as in Example 1, and the production speed is 25 m / min to meet the needs of production. The spray device 7 is located at 10 cm above the drum scraper 6, forming a spray liquid wet surface width of 15 cm, controlling the spray volume to be 1.5 L / min, and the spray pressure 1.0 bar. The solvent used is methylene chloride solution, and the spray device adopts polytetrafluoroethylene material , The spray works intermittently, the spray time is set for 5 seconds, and the interval is 20 seconds.

Embodiment 3

[0042] The film production process is the same as in Example 1, and the production speed is 30 m / min to meet the needs of production. The spraying device 7 is located 70 cm above the drum scraper 6, forming a wet spray surface with a width of 45 cm, controlling the spray volume at 1.5 L / min, and the spray pressure at 2 bar. The solvent used is a mixed solution of methyl acetate and methanol (volume ratio (1 : 1), the spray device 7 is made of metal titanium, and the spraying adopts intermittent working mode, the spraying time is set to 20 seconds, and the interval is 100 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com