Energy-saving calcining method for increasing activity of coal gangue

A technology for coal gangue and activity, which is applied in the field of energy-saving calcination for improving the activity of coal gangue, can solve the problems of insufficient utilization or utilization of heat, reduce the processing capacity of coal gangue, increase production costs, etc. The effect of uniform and controllable temperature and complete carbon combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

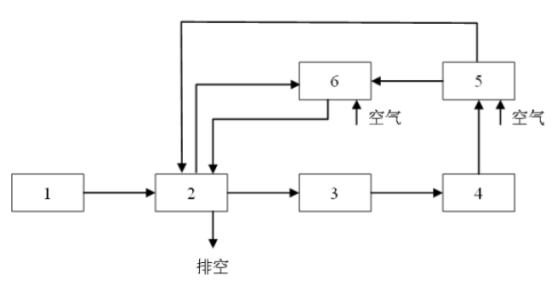

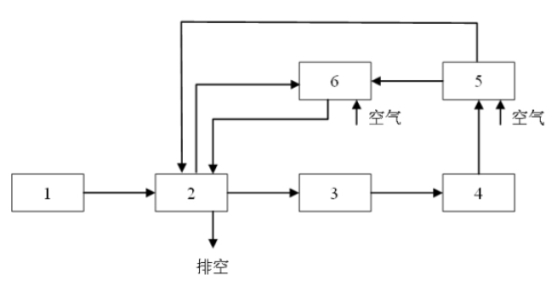

Image

Examples

Embodiment 1

[0030] Crush and grind the coal gangue with 4% carbon and 39.23% alumina until it is less than 120μm, and pyrolyze it at 550°C for 30 minutes. The temperature of the combustion furnace is 800°C, and the temperature of the secondary combustion furnace is 900°C; the leaching condition is to add 20% hydrochloric acid at a solid-to-liquid ratio of 1:4, and leaching at 90°C for 60 minutes, the alumina leaching rate is 87.95 %.

Embodiment 2

[0032] Crush and grind coal gangue containing 8% carbon and 38.22% alumina until it is less than 10 μm, and pyrolyze it at 600°C for 10 minutes. After leaching, the filtered and separated filter residue is mixed with an appropriate amount of coal and sent to the combustion furnace. The temperature of the combustion furnace is 900°C, and the temperature of the secondary combustion furnace is 1300°C; the leaching condition is to add hydrochloric acid with a concentration of 20% according to the solid-liquid ratio of 1:4, and leaching at 90°C for 60 minutes, the alumina leaching rate is 92.30 %.

Embodiment 3

[0034] Crush and grind coal gangue with 12% carbon and 35.37% alumina until it is less than 75μm, and pyrolyze it at 650°C for 15 minutes. After leaching, the filtered and separated filter residue is directly sent to the combustion furnace. The temperature of the secondary combustion furnace is 1000°C; the leaching condition is to add 20% hydrochloric acid at a solid-to-liquid ratio of 1:4, leaching at 90°C for 60 minutes, and the leaching rate of alumina is 90.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com