Vertical milling machine for precisely processing gear

A vertical milling machine, gear technology, applied in the direction of components with teeth, belts/chains/gears, gear teeth, etc., can solve the problem of spur gears failing to reach the accuracy level, etc., to achieve low cost, convenient and quick assembly and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but does not impose any limitation on the present invention.

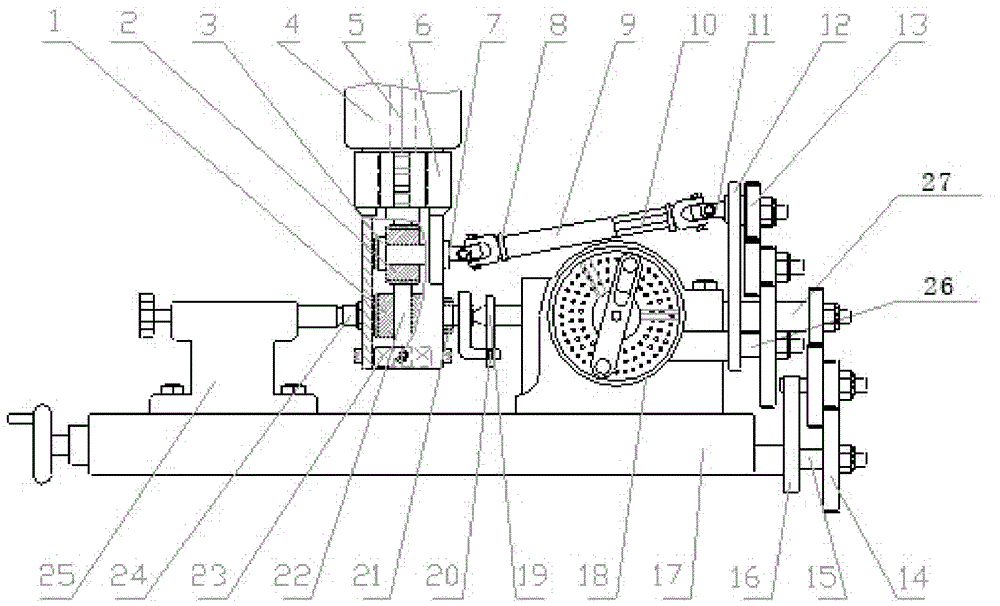

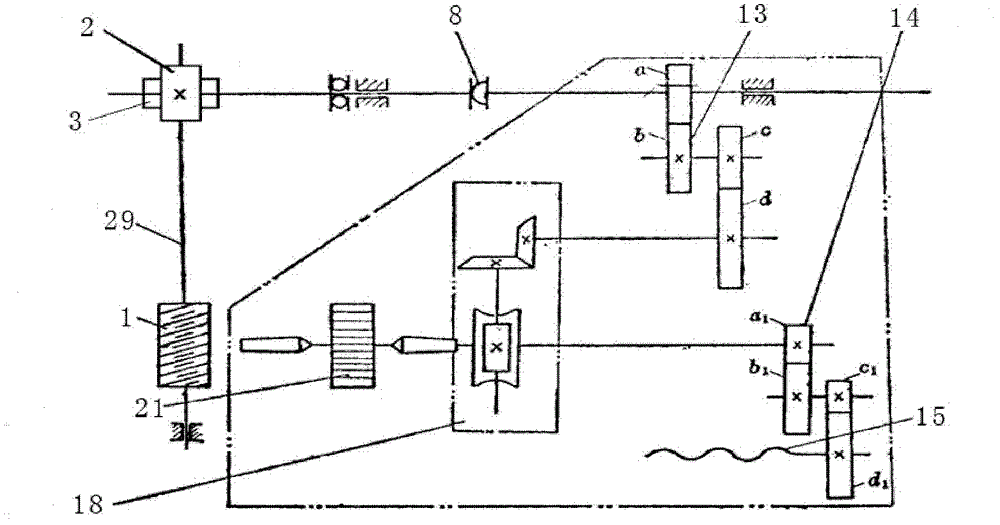

[0030] like Figure 1-6 As shown, a vertical milling machine for precisely machining gears includes a base, a bed with guide rails, a lift table, a longitudinal workbench 17, a transverse workbench, a power system, a speed change mechanism, and an electrical control system; it also includes a power output head 4 , the power output head 4 simultaneously outputs power to the gear hob 1 for milling gears and the mandrel 24 that drives the workpiece 21 to rotate, so as to realize accurate transmission between the workpiece and the gear hob 1 .

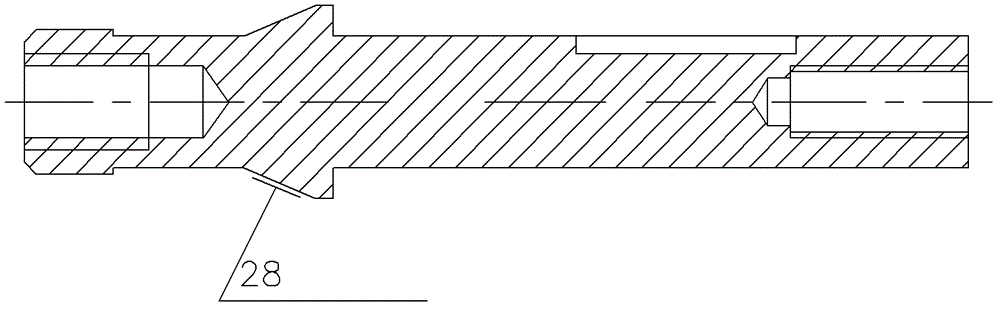

[0031] The power output head 4 includes a hob cutter bar 22, a hob bar pull rod 5, an end mill spindle, an active helical gear 2, and an output helical gear 3. On the main shaft, the active helical gear 2 and the gear hob 1 are installed on the hob cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com