Method and device for operating a resistance welding device

A technology of resistance welding and triggering device, applied in welding power supply, welding power supply and other directions, can solve the problem of increased switching loss, etc., and achieve the effect of small resistance, small volume, and less magnetization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

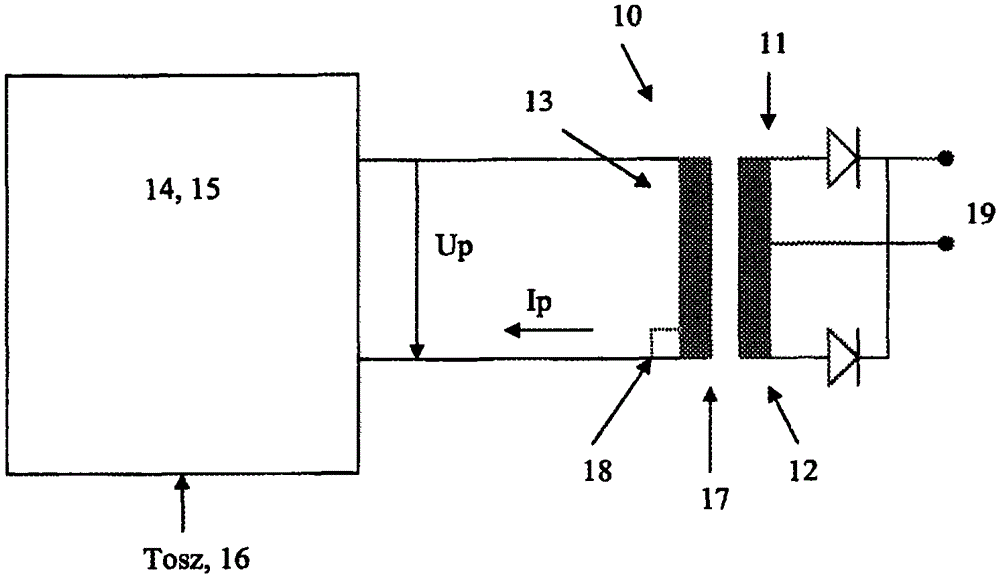

[0025] attached figure 1 A medium frequency welding transformer with a rectifier and a converter is shown schematically and is generally designated with reference numeral 10 . Device 10 can be divided into different components. The device has a primary circuit 13 and secondary circuits 11 , 12 , which are connected via a transformer 17 in such a way that a common magnetic flux is generated within the windings of the primary circuit 13 and the secondary circuits 11 , 12 . The primary winding 13 with the number of turns of the transformer 17 being N1 is connected to the primary circuit and the number of turns of the transformer 17 is respectively N 2 +N 3 The secondary windings 11, 12 are connected to the secondary circuit. The transformer 17 also has a transformer core, but this is not shown here for the sake of clarity.

[0026] In the secondary circuit 11 , 12 there is an output area indicated by reference numeral 19 , to which a welding electrode can be connected. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com