Multi-station sapphire single-wire swinging cutting machine

A sapphire, multi-station technology, used in work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of small diameter of the take-up and pay-off reel, decreased cutting ability, and increased cutting wire volume, and achieves reduction of cutting wire. The effect of reducing cutting cost and increasing cutting output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

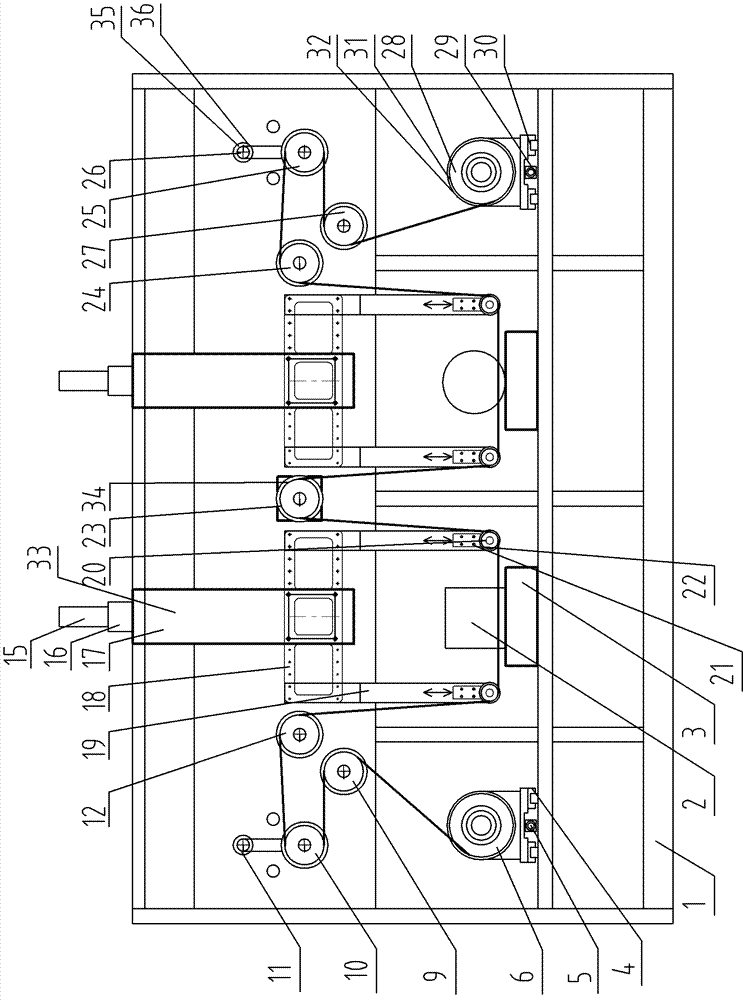

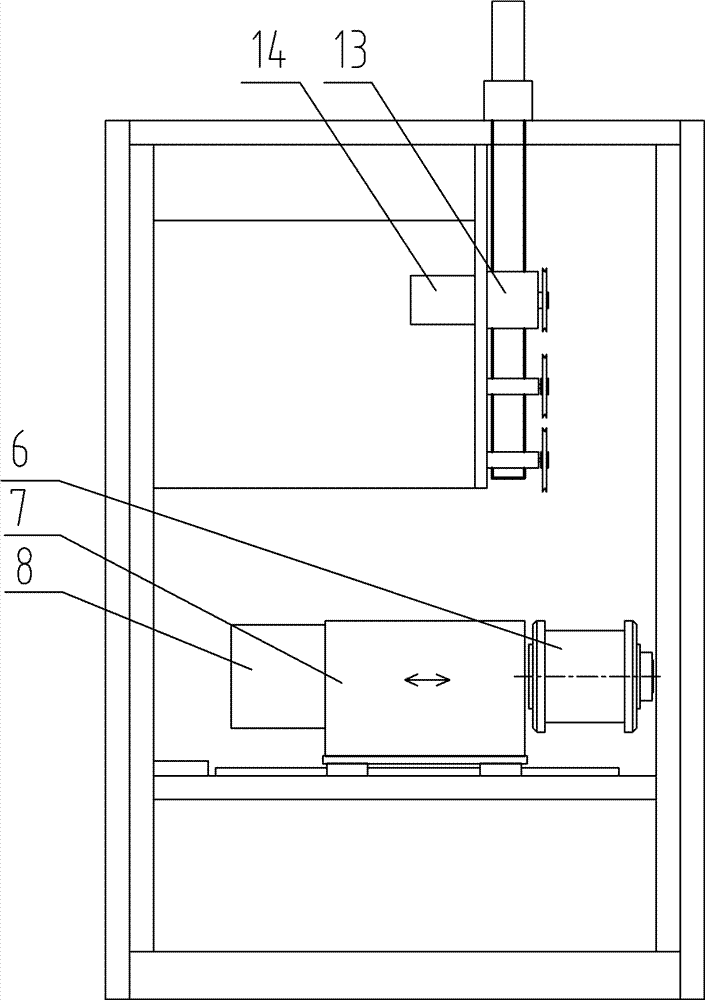

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0019] like Figure 1~2 In the illustrated embodiment, the present invention mainly includes a frame 1, a workpiece loading fixture 3, a pay-off barrel spindle 7, a pay-off servo motor 8, a take-up barrel spindle 31, a take-up servo motor 32, and a pay-off aluminum I-shaped wheel 6 , the left tension servo motor 13, the workbench lifting servo motor 15, the cutting fixed plate 18, the swing cutting arm 19 and the take-up aluminum I-shaped wheel 28, the middle part of the frame 1 is provided with a plurality of workpiece loading fixtures 3, each A sapphire workpiece 2 is clamped on the workpiece loading fixture 3 . The workpiece loading jig 3 generally has a selection range of 2 to 5, which is more suitable, and too many are inconvenient to operate.

[0020] The two ends of the frame 1 are also respectively provided with a first linear guide rail 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com