Electromagnetic magnetic rail brake and control method thereof

A magnetic rail brake, electromagnetic technology, applied in the direction of brakes interacting between brake elements and rails, railway braking systems, railway car body components, etc., can solve the problem of electromagnetic magnetic rail brakes that cannot work and electromagnets that are too large , small excitation ampere-turns, etc., to achieve the effect of reducing volume and weight, good braking effect, and reducing magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

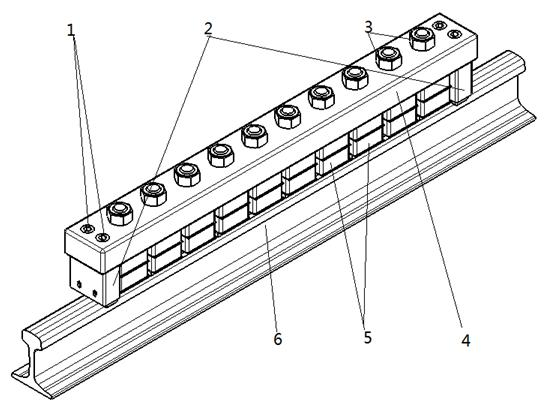

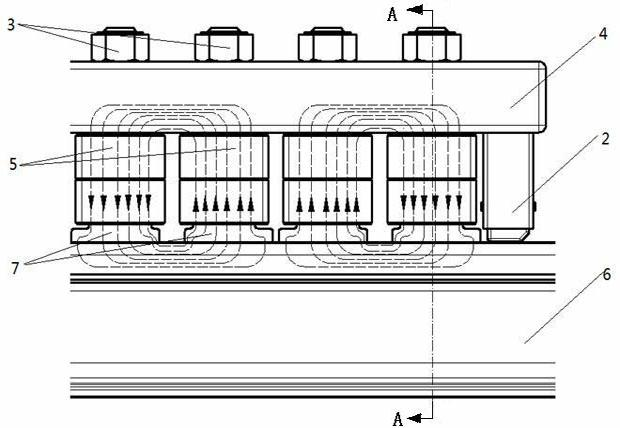

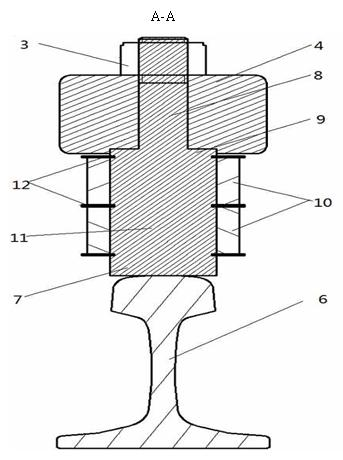

[0025] Such as Figure 1-2 As shown, the electromagnetic rail brake of the present invention is installed in pairs between the two wheels of the bogie on both sides of the rail vehicle, and an electromagnetic rail brake includes a longitudinal beam 4, and the longitudinal beam 4 is other parts and electromagnetic The basic component for connecting or installing the magnetic track brake; the longitudinal beam 4 is located on the upper part of the track 6, parallel to the track 6 and arranged along the longitudinal direction of the track, and the longitudinal space between the track 6 and the longitudinal beam 4 is provided with 2 n ( n ≥2, the same below) electromagnet 5, these 2 n Each electromagnet 5 is distributed along the longitudinal equidistant distance of track 6, and each electromagnet 5 is directly above track 6, and the axial direction of each electromagnet 5 is all vertically perpendicular to track 6 and stringer 4 simultaneously.

[0026] see Figure 2-6, each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com