Method for enhancing early strength of steel slag cement

A technology of early strength and steel slag, applied in cement production and other directions, can solve the problem that the early strength of steel slag cement cannot be further improved, and achieve the effects of saving resource consumption, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: (the specific surface involved in the embodiment is the result that utilizes Burr's specific surface area measuring instrument to measure)

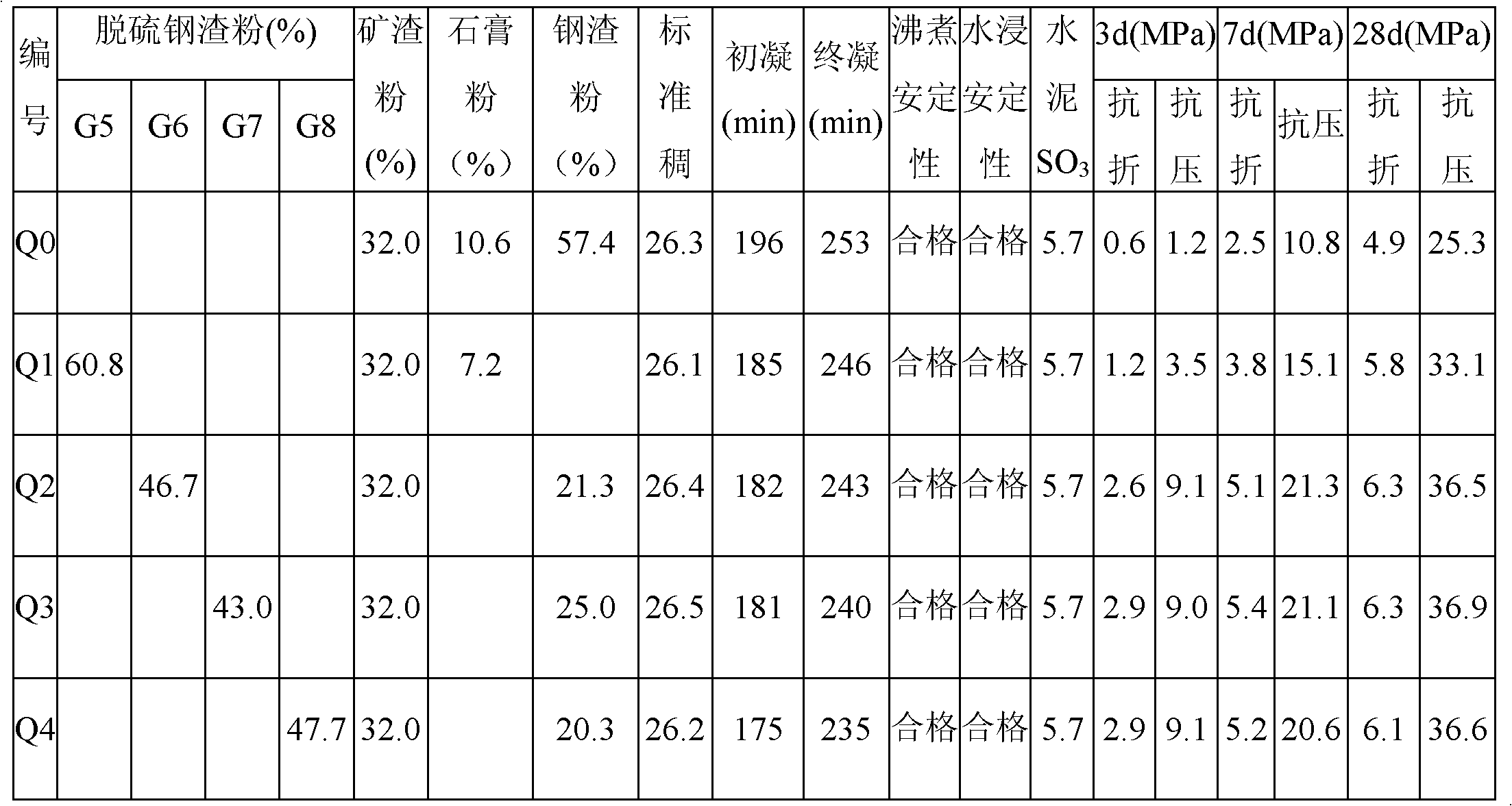

[0029] After the steel slag is dried to a moisture content of less than 1wt%, it is separately ground into several steel slag powders with different specific surface areas, and then used as a desulfurizer to absorb sulfur in the sulfur-containing flue gas, and the sulfur trioxide content in the desulfurized steel slag At 2wt% to 15wt%, several different desulfurized steel slags were obtained, and then dried until the moisture content was less than 1wt%, and then ground into desulfurized steel slag powders with specific surface areas shown in the table below, and the sulfur trioxide content was measured. See Table 1, spare.

[0030] Table 1. Specific surface area of steel slag and sulfur trioxide content after desulfurization

[0031] Numbering

G5

G6

G7

G8

Specific surface ar...

Embodiment 2

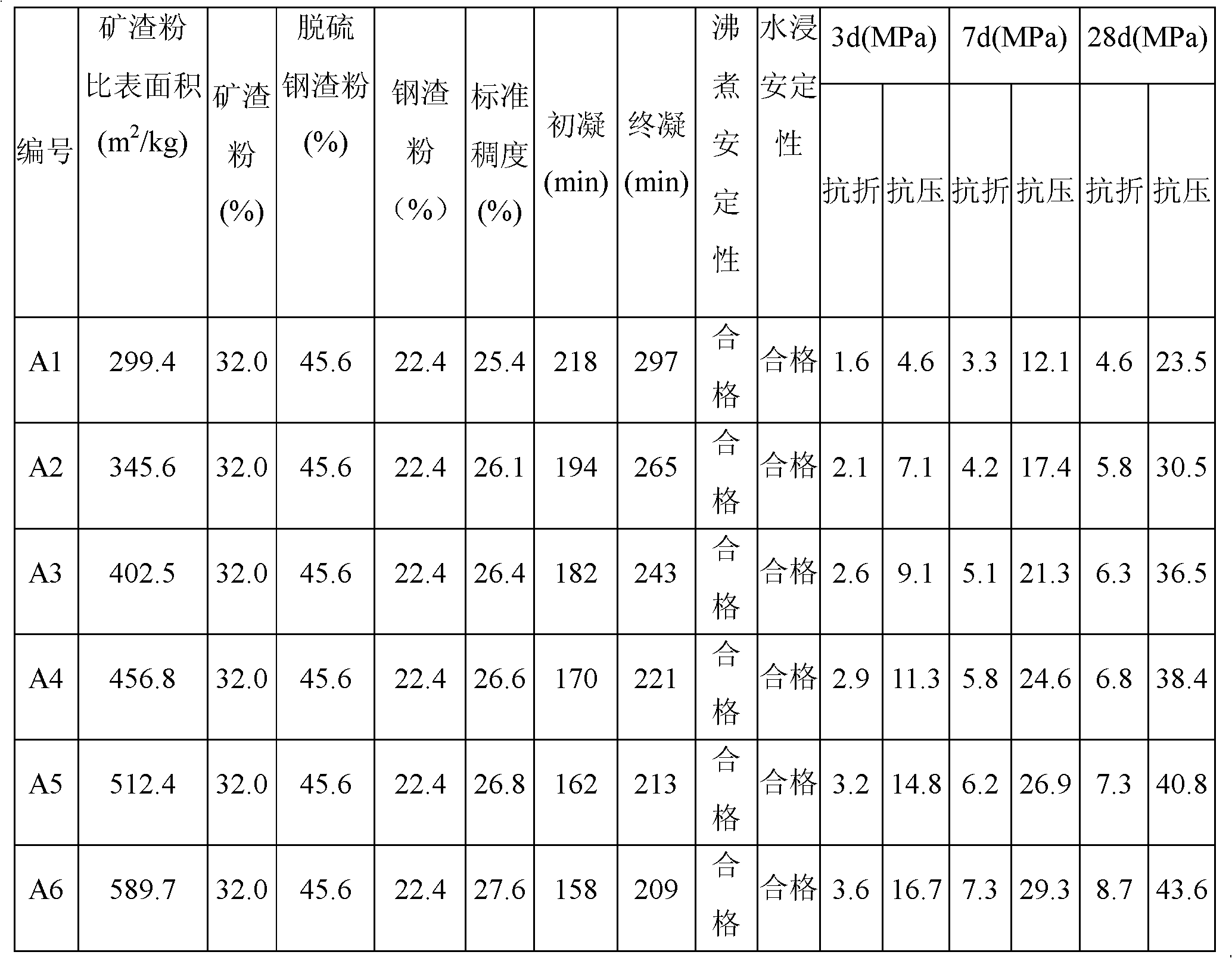

[0041] Add water to the steel slag and grind it separately to form a steel slag slurry with a moisture content of 40wt%-50wt% (the specific surface area is 325.6m3 after sampling and drying. 2 / kg), and then used as a desulfurizer to absorb the sulfur in the sulfur-containing flue gas to obtain desulfurized steel slag with a sulfur trioxide content of less than 13wt%, and then dried at a high temperature to become desulfurized steel slag with a moisture content of less than 2.0wt%. The final specific surface area is 423.1m 2 / kg of desulfurized steel slag powder, the actual measurement of its sulfur trioxide content is 12.5wt%, for subsequent use.

[0042] Grind the dried slag with a moisture content less than 1wt% separately to several slag powders with different specific surface areas for use; grind the dried steel slag separately to a specific surface area of 339.4m 2 / kg steel slag powder, spare.

[0043] Then, mix desulfurized steel slag powder, slag powder, and steel...

Embodiment 3

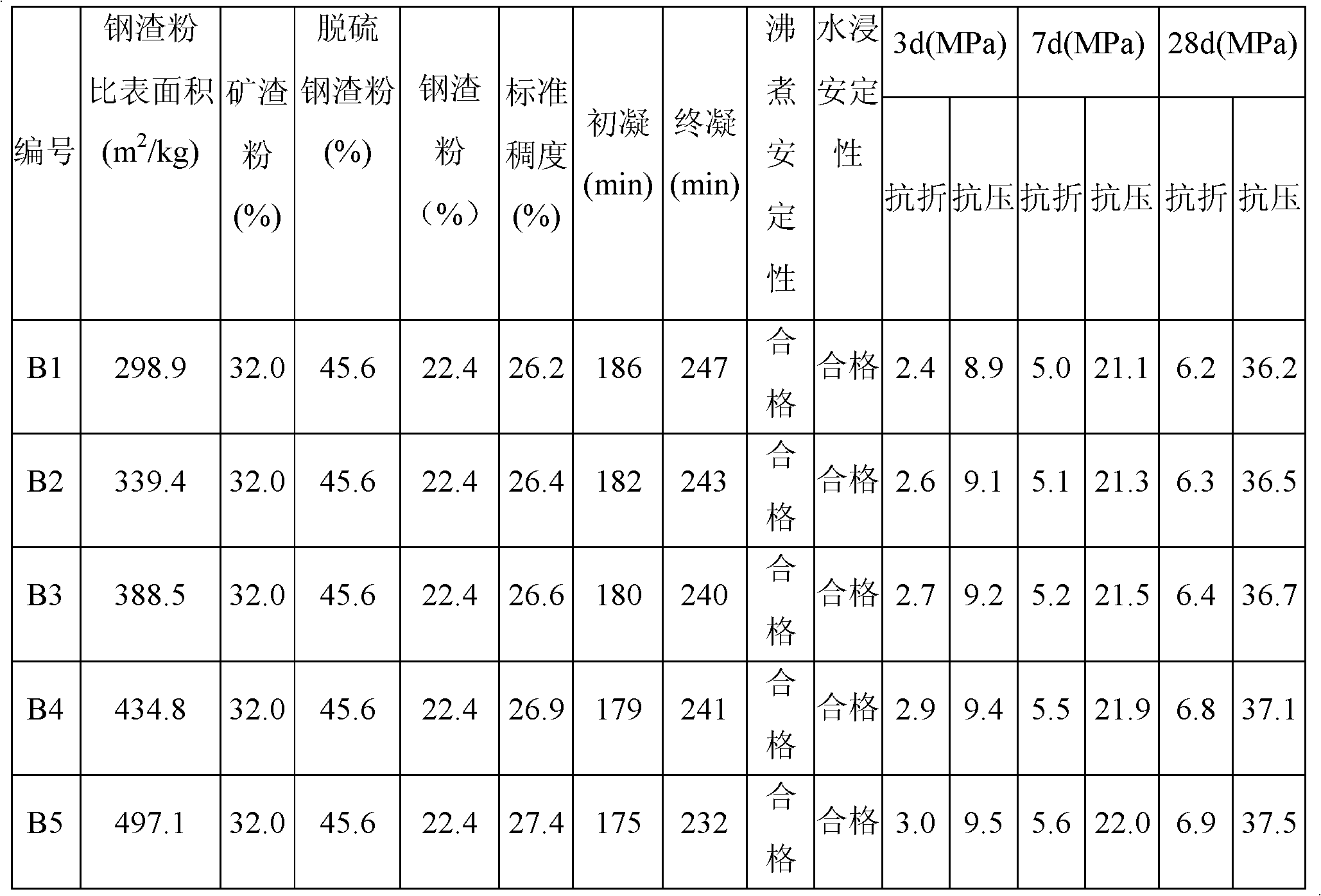

[0050] Add water to the steel slag and grind it separately to form a steel slag slurry with a water content of 50wt%-60wt% (the specific surface area is 325.6m3 after sampling and drying. 2 / kg), and then used as a desulfurizer to absorb sulfur in sulfur-containing flue gas to obtain desulfurized steel slag with a sulfur trioxide content of less than 13wt%. After being dried to a moisture content of less than 2.5wt%, it is ground to obtain a specific surface area of 402.5m 2 / kg of desulfurized steel slag powder, the actual measurement of its sulfur trioxide content is 12.5wt%, for subsequent use.

[0051] Separately grind the dried slag to a specific surface area of 420.2m 2 / kg slag powder, for use; grind the dried steel slag separately to several steel slag powders with different specific surface areas, for use.

[0052] Then, mix desulfurized steel slag powder, slag powder and steel slag powder uniformly according to the ratio in Table 4 to prepare steel slag cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com