Building cement-based penetration hardening material and preparation method thereof

A cement-based, water-based technology, which is applied to the hardening material of the concrete base and penetrates into the field of cement mortar, can solve the problems of failing to completely improve the strength of the concrete structure, the complex preparation process, and the waste of materials, and achieve good adaptability and preparation process. Simple, simple construction and operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

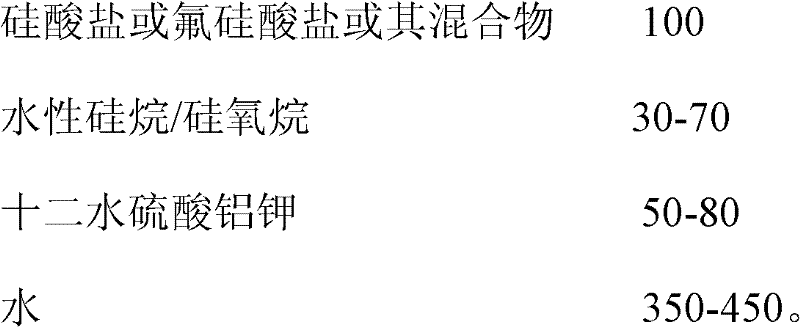

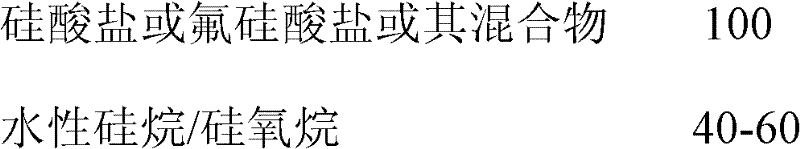

[0055] In Examples 1-5, according to the component weight ratios shown in Table 1, five kinds of cement-based permeable hardening materials of the present invention were respectively prepared, and their improvements to the wear resistance of C25 cement concrete were measured respectively.

[0056] Table 1 Several cement-based hardening material formulations with different proportions

[0057]

[0058] Paint the cement-based penetrating hardening material prepared according to the above formula on the surface of C25 cement concrete, and after drying for a week, grind it according to the method described in GB / T 12988, and evaluate the wear resistance of the cement concrete material by measuring the length of the grinding pit. With the standard C25 cement concrete that is not processed by the cement-based permeable hardening material of the present invention as a contrast, the length of the grinding pit of the cement concrete that is processed by the cement-based permeable har...

Embodiment 6-11

[0064] In Examples 6-11, six alkali mixtures were prepared according to the weight ratios of the components shown in Table 3.

[0065] Alkali mixture formulas of several different proportions of table 3

[0066] composition

Example 6

Example 7

Example 8

Example 9

Example 10

Example 11

water

100

100

100

100

100

100

0.10

0.12

0.14

0.16

0.18

0.20

magnesium hydroxide

0.009

0.007

0.005

0.003

0.002

0

[0067] Brush the alkali mixture obtained above on the surface of C25 cement concrete respectively, and then paint the cement-based permeable hardening material of the present invention prepared according to the formula of Example 3 on the surface of the concrete after drying for one week. Grinding by the method described in / T 12988, the wear resistance of cement concrete materials is evaluated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com