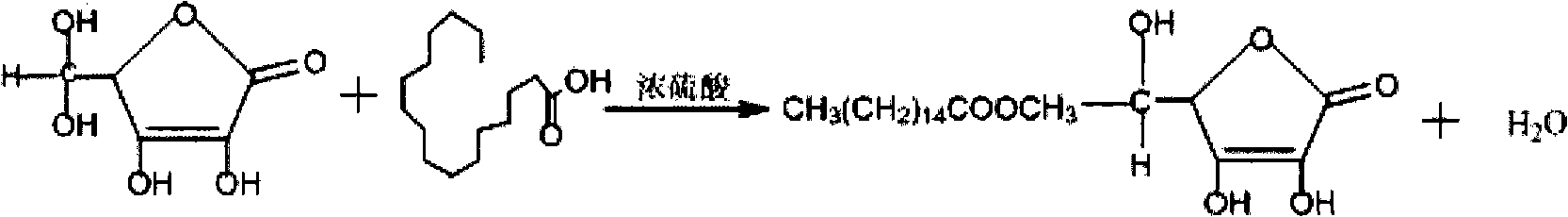

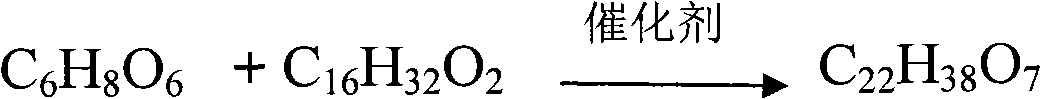

Preparation method of L-ascorbyl palmitate

A technology of ascorbyl palmitate and ascorbic acid, which is applied in the field of preparation of L-ascorbyl palmitate, can solve the problems of low yield and poor purity of L-ascorbyl palmitate, achieves good appearance, improves quality and purity, and improves reagent quality. A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation

[0025] Add 8.0g of L-ascorbic acid and 45.0ml of concentrated sulfuric acid into a 250.0mL three-necked flask, heat it to 30.0°C under stirring, slowly add 16.0g of palmitic acid dropwise, and keep the inner temperature of the three-necked flask at about 30.0°C during the dropping process. Minutes dropwise completed, constant temperature reaction 32h.

[0026] (2) Extraction

[0027] After the reaction, the reaction system was extracted with an ice-water mixture with a ratio of ice and water of 1:1. The volume of the ice-water mixture was about 180ml, and then the ice-water solution was extracted with ethyl acetate, and the extract was distilled under reduced pressure to obtain a solid , and dried in an oven at 50°C to obtain 17.1 g of a yellow solid crude product.

[0028] (3) refined

[0029] The resulting 17.1g solid and 68.0mL petroleum ether: absolute ethanol = 1:0.4 (volume ratio) were stirred in a three-necked flask at 55.0°C until the soluti...

Embodiment 2

[0031] (1) Preparation

[0032] Add 8.0g of L-ascorbic acid and 36.0ml of concentrated sulfuric acid to a 250.0mL three-necked flask, heat it to 27°C while stirring, slowly add 12.8g of palmitic acid dropwise, and keep the inner temperature of the three-necked flask at about 27°C during the dropping process for 20 minutes After the addition was completed, the reaction was carried out at a constant temperature for 30 hours.

[0033] (2) Extraction

[0034] After the reaction, the reaction system was extracted with an ice-water mixture with a ratio of ice and water of 1:1. The volume of the ice-water mixture was about 250ml, and then the ice-water solution was extracted with dichloromethane, and the extract was distilled under reduced pressure to obtain a solid , placed in a 50°C oven and dried to obtain 16.5 g of a yellow solid crude product.

[0035] (3) refined

[0036] The resulting 16.5g solid and 65.0mL petroleum ether: absolute ethanol = 1:0.45 (volume ratio) were stir...

Embodiment 3

[0038] (1) Preparation

[0039] Add 8.0g of L-ascorbic acid and 60.0ml of concentrated sulfuric acid into a 250.0mL three-necked flask, heat it to 30°C while stirring, slowly add 17.0g of palmitic acid, and keep the inner temperature of the three-necked flask at about 30°C during the dropping process for 40 minutes After the addition was completed, the reaction was carried out at a constant temperature for 35 hours.

[0040] (2) Extraction

[0041] After the reaction, the reaction system was extracted with an ice-water mixture with a ratio of ice and water of 1:1. The volume of the ice-water mixture was about 200ml, and then the ice-water solution was extracted with ethyl acetate, and the extract was distilled under reduced pressure to obtain a solid , placed in a 50°C oven and dried to obtain 18.2 g of a yellow solid crude product.

[0042] (3) refined

[0043] The resulting 18.2g solid and 70.0mL petroleum ether: absolute ethanol = 1:0.4 (volume ratio) were stirred in a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com