Bis(pinacolato)diboron production process

A kind of biboronic acid pinacol ester, the technology of production technology, applied in the field of biboronic acid pinacol ester production technology, can solve the problems of waste of resources, low reaction conversion rate, low product yield, etc., to avoid extremely low temperature conditions, Effects of improving safety and improving reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

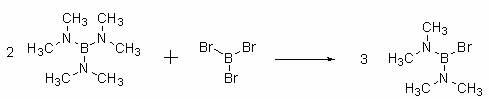

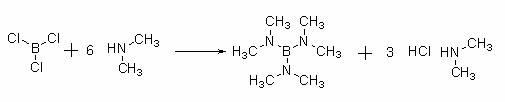

[0016] The production technology of pinacol ester of diboronic acid comprises the steps:

[0017] (1) First, add 1900 parts by volume of n-hexane with a mass concentration of 97% into a four-necked bottle equipped with a mechanical stirrer, a thermometer, an exhaust gas absorption device and a condenser tube, and stir, then introduce 180 parts by mass of boron trichloride gas , under the condition of 10°C and normal pressure, 470 parts by mass of dimethylamine gas was introduced to carry out the amination reaction, and then the precipitated salt was removed by suction filtration, and the filtrate was re-added into the four-necked bottle;

[0018] (2) Add 210 parts by mass of boron tribromide dropwise to the above filtrate within 55 minutes, and react for 4.5 hours at normal temperature and pressure. Distill to obtain n-hexane first, then reduce the pressure to -0.09MPa, cool down to 60°C to distill the intermediate;

[0019] (3) Take another four-necked bottle, add 2900 parts...

Embodiment 2

[0022] The production technology of pinacol ester of diboronic acid comprises the steps:

[0023] (1) First add 2000 parts by volume of n-hexane with a mass concentration of 98% into a four-neck bottle equipped with a mechanical stirrer, a thermometer, an exhaust gas absorption device and a condenser tube, and stir, then feed 200 parts by mass of boron trichloride gas , under the condition of 12°C and normal pressure, 480 parts by mass of dimethylamine gas was introduced to carry out the amination reaction, and then the precipitated salt was removed by suction filtration, and the filtrate was re-added into the four-necked bottle;

[0024] (2) Add 220 parts by mass of boron tribromide dropwise to the above filtrate within 60 minutes, and react for 5 hours at normal temperature and pressure. Distill to obtain n-hexane first, then reduce the pressure to -0.095MPa, cool down to 62°C to distill the intermediate;

[0025] (3) Take another four-necked bottle, add 3000 parts by volum...

Embodiment 3

[0028] The production technology of pinacol ester of diboronic acid comprises the steps:

[0029] (1) First add 2100 parts by volume of n-hexane with a mass concentration of 99% into a four-necked bottle equipped with a mechanical stirrer, a thermometer, an exhaust gas absorption device and a condenser tube, and stir, then feed 210 parts by mass of boron trichloride gas , under the condition of 15°C and normal pressure, 490 parts by mass of dimethylamine gas was introduced to carry out the amination reaction, and then the precipitated salt was removed by suction filtration, and the filtrate was re-added into the four-necked bottle;

[0030] (2) Add 230 parts by mass of boron tribromide dropwise to the above filtrate within 65 minutes, and react for 5.5 hours at normal temperature and pressure. First distill to obtain n-hexane, then reduce the pressure to -0.1MPa, cool down to 65°C to distill the intermediate;

[0031] (3) Take another four-necked bottle, add 3100 parts by vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com