Method for one-step recovery and modification of carbon fiber

A carbon fiber and modification technology, which is applied in the field of one-step recovery and modification of carbon fiber, can solve the problems of limited promotion and application, high price of carbon fiber, etc., and achieve the effect of broadening the application range, simple reaction steps, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

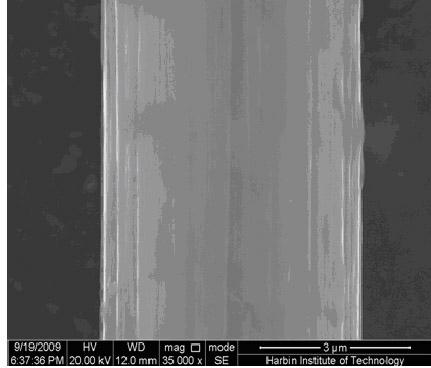

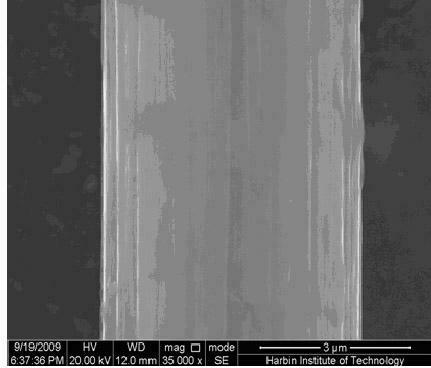

Image

Examples

Embodiment 1

[0015] Embodiment 1: With the recovered epoxy resin carbon fiber composite material as the initial raw material, it is broken into small pieces with length × width × thickness equal to 10 × 4 × 3cm by a hammer crusher; water is used as the liquefaction solution and sodium carbonate as the The catalyst decomposes the recycled epoxy resin carbon fiber composite material by hydrothermal method, and finally obtains the recycled carbon fiber with excellent mechanical properties and active groups such as -COOH and -OH on the surface.

[0016] Step (1): Break the recovered epoxy resin carbon fiber composite material into small pieces with length × width × thickness equal to 10 × 4 × 3cm through a hammer crusher; then crush the epoxy resin carbon fiber composite material in small pieces Dry at 100°C for 1 hour;

[0017] Step (2): Add 800mL of water and 8g of sodium carbonate in the autoclave, stir with a glass rod for 15 minutes, then add 200g of dried epoxy resin carbon fiber composi...

Embodiment 2

[0020] Example 2: Using the recovered unsaturated resin carbon fiber composite material as the initial raw material, it is broken into small pieces with length × width × thickness equal to 10 × 4 × 3cm by a hammer crusher; water is used as the liquefaction solution and sulfuric acid as the catalyst The recycled unsaturated resin carbon fiber composite material is hydrothermally decomposed, and finally the recycled carbon fiber with excellent mechanical properties and active groups such as -COOH and -OH attached to the surface is obtained.

[0021] Step (1): Break the recovered unsaturated resin carbon fiber composite material into small pieces with length × width × thickness equal to 10 × 4 × 3cm through a hammer crusher; then crush the unsaturated resin carbon fiber composite material in small pieces Dry at 80°C for 2 hours;

[0022] Step (2): Add 800mL of water and 8mL, 90% weight concentration of sulfuric acid solution in the autoclave, stir with a glass rod for 10 minutes,...

Embodiment 3

[0024] Embodiment 3: With the reclaimed phenolic resin carbon fiber composite material as the initial raw material, it is broken into small pieces with length × width × thickness equal to 10 × 4 × 3cm by a hammer crusher; with absolute ethanol as the liquefaction solution and sulfuric acid as The catalyst decomposes the recovered phenolic resin carbon fiber composite material by hydrothermal method, and finally obtains the recovered carbon fiber with excellent mechanical properties and active groups such as -COOH and -OH attached to the surface.

[0025] Step (1): Break the recovered phenolic resin carbon fiber composite material into small pieces equal to 10×4×3cm in length×width×thickness through a hammer crusher; Dry for 2 hours;

[0026] Step (2): Add 900mL of absolute ethanol and 9mL, 90% weight concentration sulfuric acid solution in the autoclave, stir with a glass rod for 10 minutes, then add 300g of dried phenolic resin carbon fiber composite material small pieces, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average young's modulus | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com