Hydroxy-terminated polyether type macromolecular fluorescent dye and synthesis method thereof

A technology of hydroxyl-terminated polyether and fluorescent dyes, which is applied in the field of fluorescent dyes and its preparation, can solve the problems that polymer dyes do not have fluorescent properties, and achieve the effects of good UV resistance stability, high fluorescence intensity, and difficult solvent extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

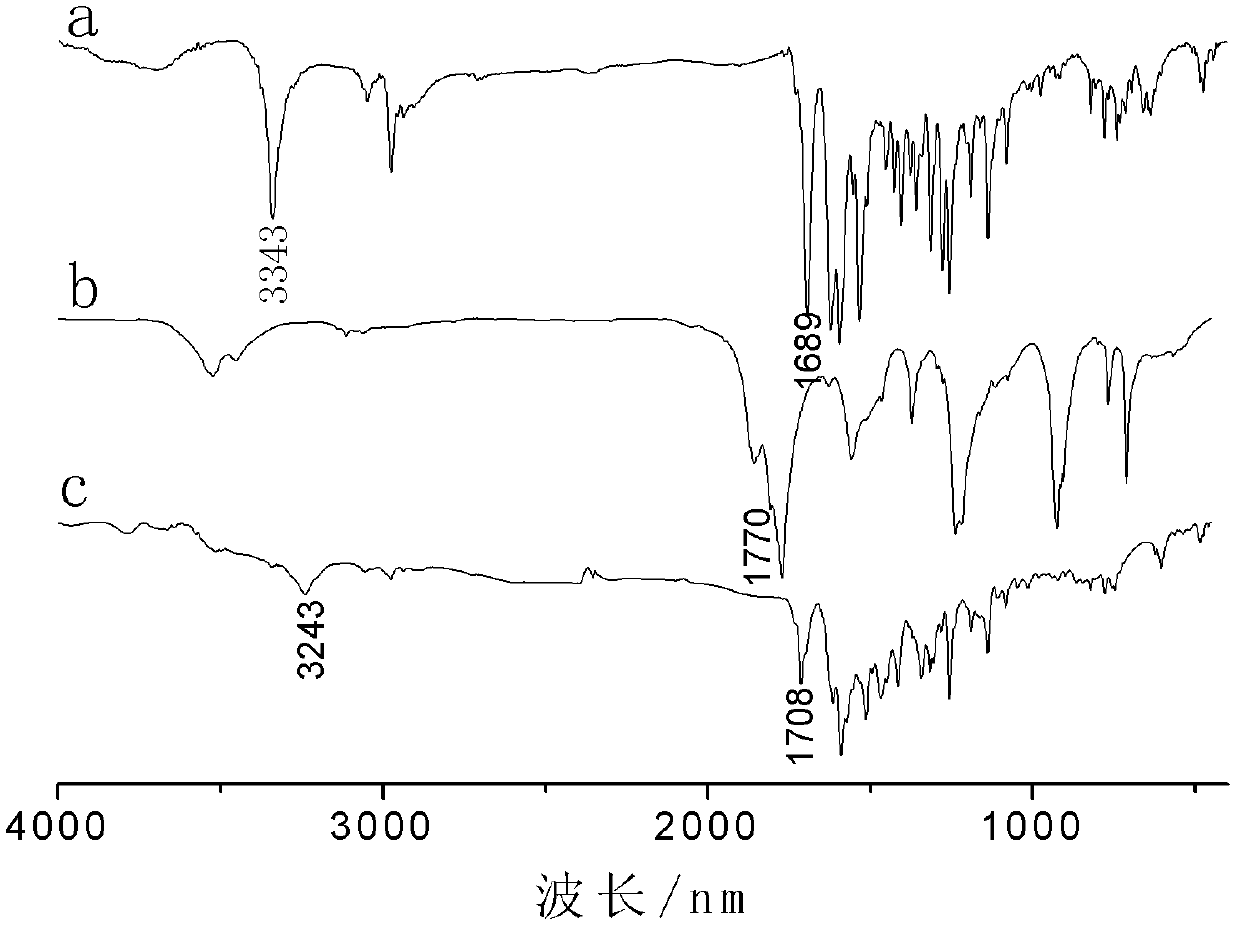

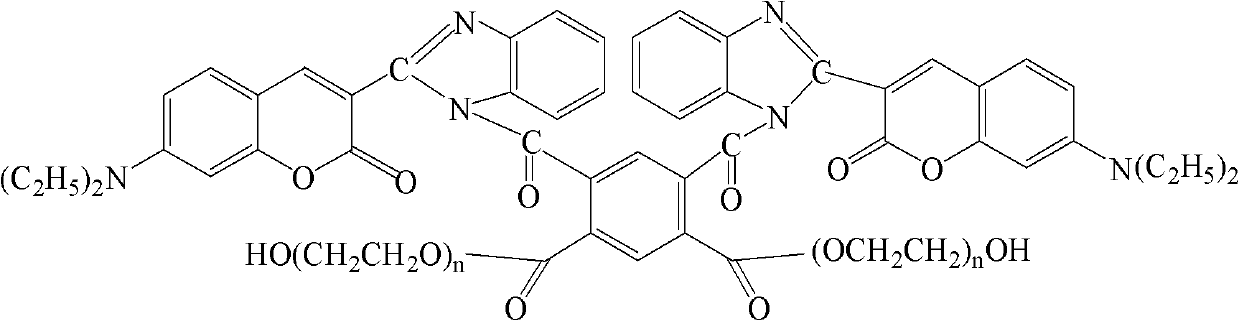

[0023] In this embodiment, the hydroxyl-terminated polyether type polymer fluorescent dye is prepared according to the following method:

[0024] Add 1.2g of pyromellitic dianhydride (PMDA), 3.3g of Fluorescent Yellow 8GFF and 140mL of dried DMF solvent into a 250mL four-necked flask, stir and dissolve until the system becomes a transparent solution, heat the water bath to 80°C for constant temperature reaction, and react for 0.5 After 2 hours, the product precipitated out of the system, and the constant temperature reaction was continued for 2 hours before stopping. After washing with DMF and filtering three times, the product was dried in a blast oven at 80°C to obtain 3.9 g of 8GFF-PMDA condensation intermediate, with a yield of 86.7%.

Embodiment 2

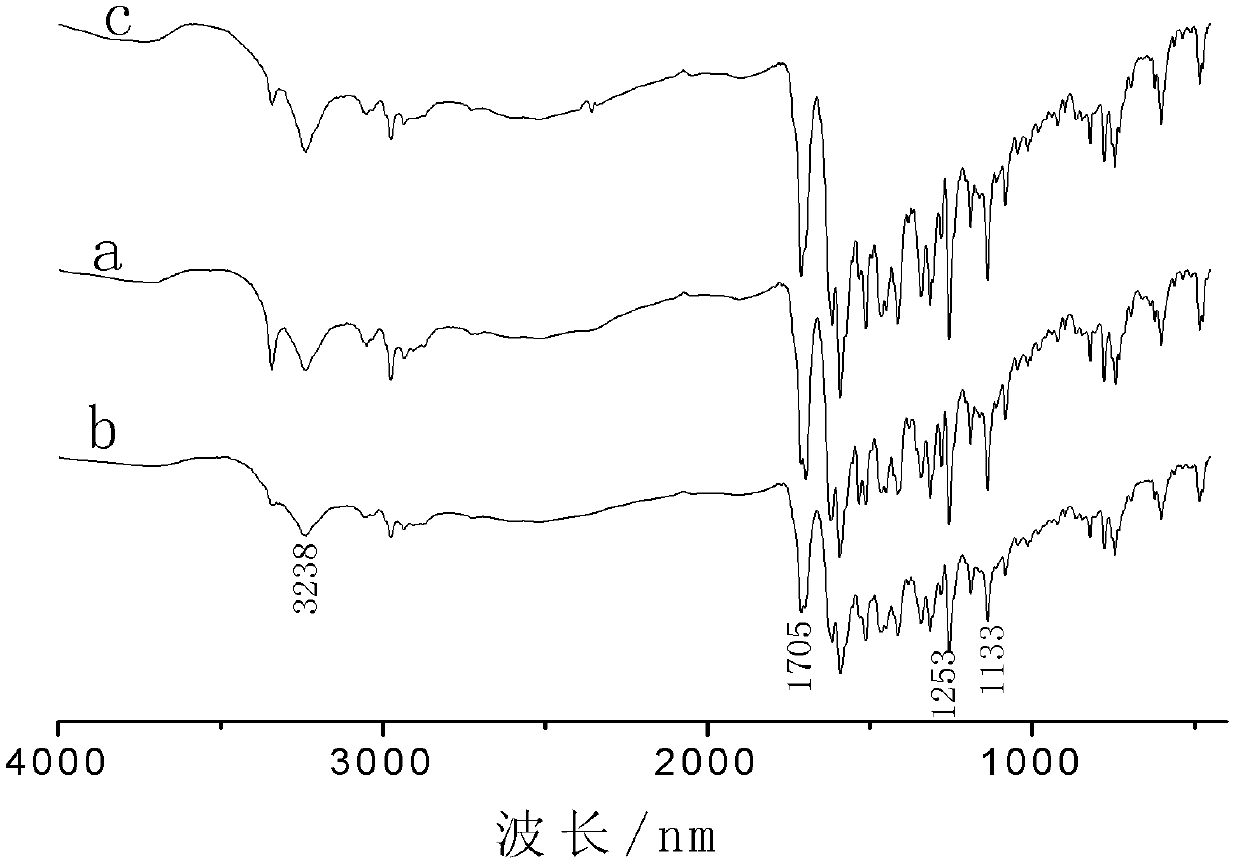

[0026] In a 50mL single-necked flask, add 0.88g 8GFF-PMDA condensation intermediate (0.001mol) and 3.00g vacuum-dried PEG600 with a constant weight average molecular weight of 600, then add 10mL dry DMF solvent containing 0.004mol concentrated sulfuric acid catalyst, and magnetically stir to dissolve , the temperature of the oil bath was raised to 140°C for constant temperature reaction for 5h. After the reaction, neutralize the system with a saturated solution of sodium carbonate until the pH value is 7, add methanol to the system to precipitate the product; filter the obtained product, wash and filter the filter residue repeatedly with distilled water to remove unreacted PEG, and then vacuum dry at 60°C to Constant weight was obtained to obtain 0.87 g of hydroxyl-terminated polyether type 8GFF-PMDA-PEG polymer fluorescent dye. The average molecular weight of the polymer fluorescent dye prepared in this example is 2050.

Embodiment 3

[0028] PEG with a molecular weight of 1000 was vacuum-dried at 80° C. for 3 h in a single-necked flask for later use. Add 0.88g 8GFF-PMDA condensation intermediate (0.001mol) and 5.00g average molecular weight in 50mL single-necked flask and be PEG1000 of 1000, then add 10mL dry DMF solvent containing 0.005mol concentrated sulfuric acid catalyst, magnetic stirring dissolves, oil bath is heated up to 140 ℃ constant temperature reaction 5h. After the reaction, neutralize the system with a saturated solution of sodium carbonate until the pH value is 7, add methanol to the system to precipitate the product; filter the obtained product, wash and filter the filter residue repeatedly with distilled water to remove unreacted PEG; vacuum dry at 60°C to constant weight 1.45 g of hydroxyl-terminated polyether-type 8GFF-PMDA-PEG polymer fluorescent dye was obtained. The average molecular weight of the polymer fluorescent dye prepared in this example is 2850.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com