Insulation coating coated on surface of oriented silicon steel strip

A technology of oriented silicon steel and insulating coatings, applied in anti-corrosion coatings, coatings, etc., can solve problems such as insufficient, and achieve the effect of good adhesion, good corrosion resistance, corrosion resistance or rust resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

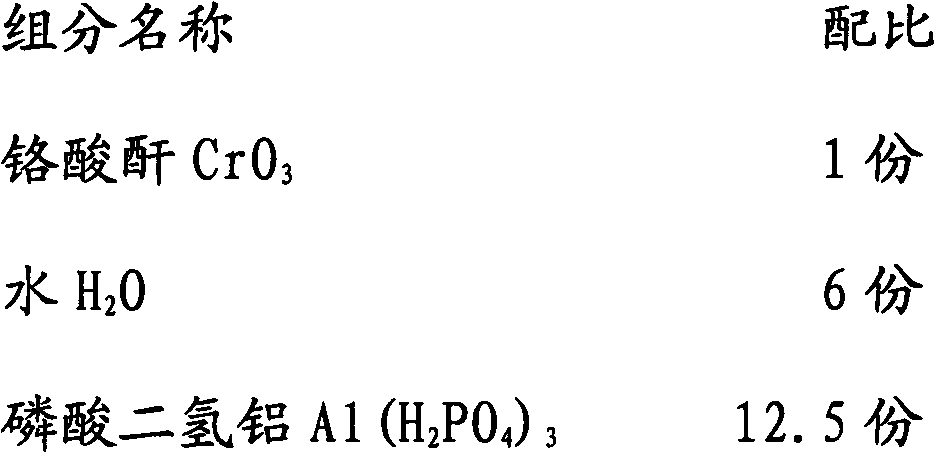

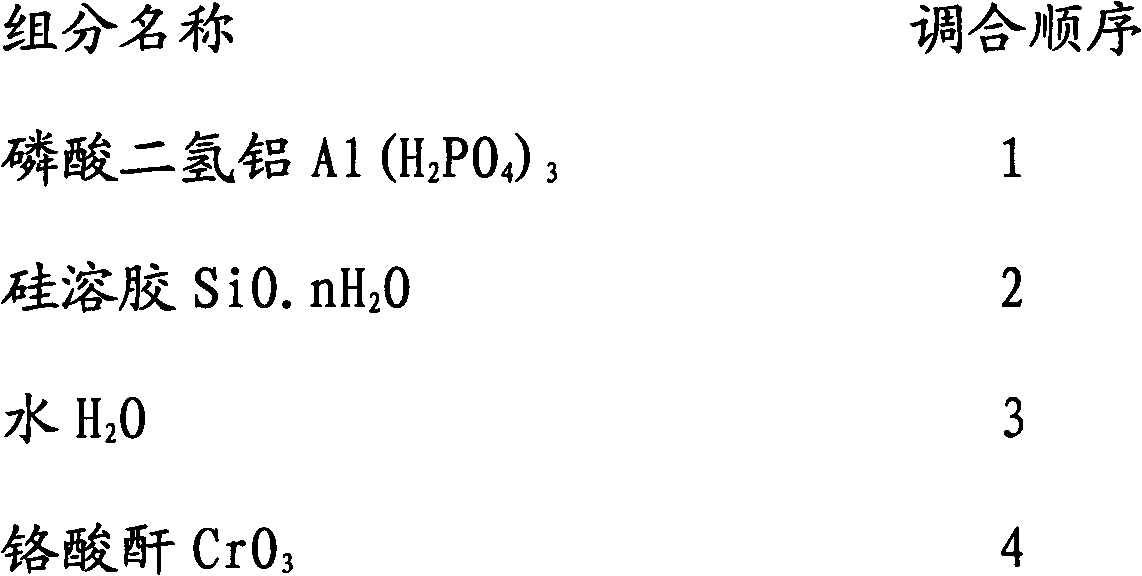

[0058] The following process technology and parameters are used:

[0059] 1. The formula components are: chromic anhydride (CrO 3 ), silica sol (SiO 2 .nH 2 O), aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ], water (H 2 O).

[0060] 2. The quality requirements of formula components are:

[0061] (1) Chromic anhydride (CrO 3 ):

[0062] Content: ≥99.5%

[0063] Chloride (Cl - ): ≤0.005%

[0064] Sulfate (SO 4 -2 ): ≤0.1%

[0065] Iron content≤0.005%

[0066] Water insoluble matter: ≤0.05%

[0067] Appearance: purple flake;

[0068] (2) Silica sol (SiO 2 .nH 2 O)

[0069] Content: 30±1.0%

[0070] Sodium oxide: less than 0.3%

[0071] Viscosity (25°C): less than 6.0CP;

[0072] Particle size: 10-20μm

[0073] Specific gravity (25°C): 1.201-1.210;

[0074] (3) Aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ]

[0075] Content: 50±1.0%

[0076] Phosphorus pentoxide (P 2 o 5 ): 33±1.0%

[0077] Aluminum oxide (Al 2 o 3 ): 8.5±0.5%

[0078] Ferric ...

Embodiment 2

[0101] The following process technology and parameters are used:

[0102] 1. The formula components are: chromic anhydride (CrO 3 ), silica sol (SiO 2 .nH 2 O), aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ], water (H 2 O).

[0103] 2. The quality requirements of formula components are:

[0104] (1) Chromic anhydride (CrO 3 ):

[0105] Content: ≥99.5%

[0106] Chloride (Cl - ): ≤0.005%

[0107] Sulfate (SO 4 -2 ): ≤0.1%

[0108] Iron content≤0.005%

[0109] Water insoluble matter: ≤0.05%

[0110] Appearance: purple flake;

[0111] (2) Silica sol (SiO 2 .nH 2 O)

[0112] Content: 30±1.0%

[0113] Sodium oxide: less than 0.3%

[0114] Viscosity (25°C): less than 6.0CP;

[0115] Particle size: 10-20μm

[0116] Specific gravity (25°C): 1.201-1.210;

[0117] (3) Aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ]

[0118] Content: 50±1.0%

[0119] Phosphorus pentoxide (P 2 o 5 ): 33±1.0%

[0120] Aluminum oxide (Al 2 o 3 ): 8.5±0.5%

[0121] Ferri...

Embodiment 3

[0143] The following process technology and parameters are used:

[0144] 1. The formula components are: chromic anhydride (CrO 3 ), silica sol (SiO 2 .nH 2 O), aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ], water (H 2 O).

[0145] 2. The quality requirements of formula components are:

[0146] (1) Chromic anhydride (CrO 3 ):

[0147] Content: ≥99.5%

[0148] Chloride (Cl - ): ≤0.005%

[0149] Sulfate (SO 4 -2 ): ≤0.1%

[0150] Iron content≤0.005%

[0151] Water insoluble matter: ≤0.05%

[0152] Appearance: purple flake;

[0153] (2) Silica sol (SiO 2 .nH 2 O)

[0154] Content: 30±1.0%

[0155] Sodium oxide: less than 0.3%

[0156] Viscosity (25°C): less than 6.0CP;

[0157] Particle size: 10-20μm

[0158] Specific gravity (25°C): 1.201-1.210;

[0159] (3) Aluminum dihydrogen phosphate [Al(H 2 PO 4 ) 3 ]

[0160] Content: 50±1.0%

[0161] Phosphorus pentoxide (P 2 o 5 ): 33±1.0%

[0162] Aluminum oxide (Al2 o 3 ): 8.5±0.5%

[0163] Ferric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com