Method for preparing biomass briquette by utilizing high-calcium fly ash composite binder

A technology for preparing high-calcium fly ash and binder, which is applied in the directions of biofuel and waste fuel, can solve the problems of low economy and high cost, and achieve the effects of prolonging service life, reducing power and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for preparing biomass briquette fuel by using high-calcium fly ash composite binder uses the following materials as raw materials: pulverized biomass, oily sludge, high-calcium fly ash, sodium humate, and sawdust; wherein, high-calcium fly ash Calcium fly ash, oily sludge, sodium humate and sawdust form a composite binder. The addition of composite binder accounts for about 20% of the total weight, oily sludge accounts for 10% to 20% of the binder, sodium humate accounts for 2 to 5% of the binder, high calcium pulverized coal The ash accounts for 10% of the weight of the binder, and the balance is sawdust; the pulverized biomass particles and the causticized high-calcium fly ash composite binder are evenly mixed and sent into the The molding machine produces biomass shaped pellets, which are then cooled.

[0036] Before formal preparation, the preparatory work to be done is:

[0037] Put the flue gas into the water for preparing sodium humate, heat the wate...

Embodiment 2

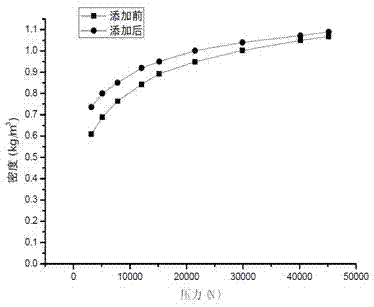

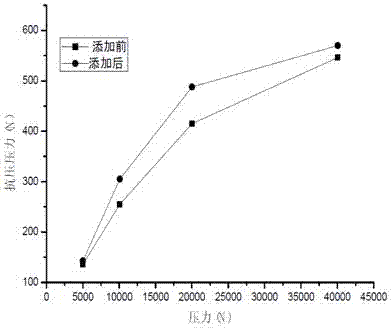

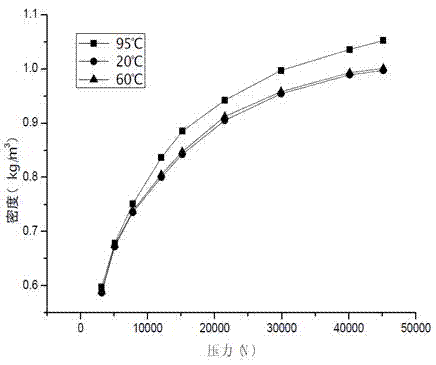

[0046]The method for preparing biomass briquette fuel by using high-calcium fly ash composite binder uses the following materials as raw materials: pulverized biomass, high-calcium fly ash, and sawdust; wherein, high-calcium fly ash and sawdust form a composite binder. The added amount of composite binder accounts for about 20% of the total weight, high-calcium fly ash accounts for 20% of the binder weight ratio, and the balance is sawdust; after crushing, it is heated to 80°C to 95°C to the biomass particles It is uniformly mixed with the causticized high-calcium fly ash composite binder, sent to a molding machine to make biomass pellets, and then cooled.

[0047] Before formal preparation, the preparatory work to be done is: mix caustic soda and sawdust, add a certain amount of water, the amount of caustic soda should not exceed 4% of the total mixture.

[0048] Mix high-calcium fly ash and sawdust mixture, heat the mixture to 100°C with flue gas, and maintain the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com