Method for extracting heterotrophic chlorella neutral oil

A technology of heterotrophic chlorella and chlorella, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problem of no wet algae oil extraction method, etc., and achieve the effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

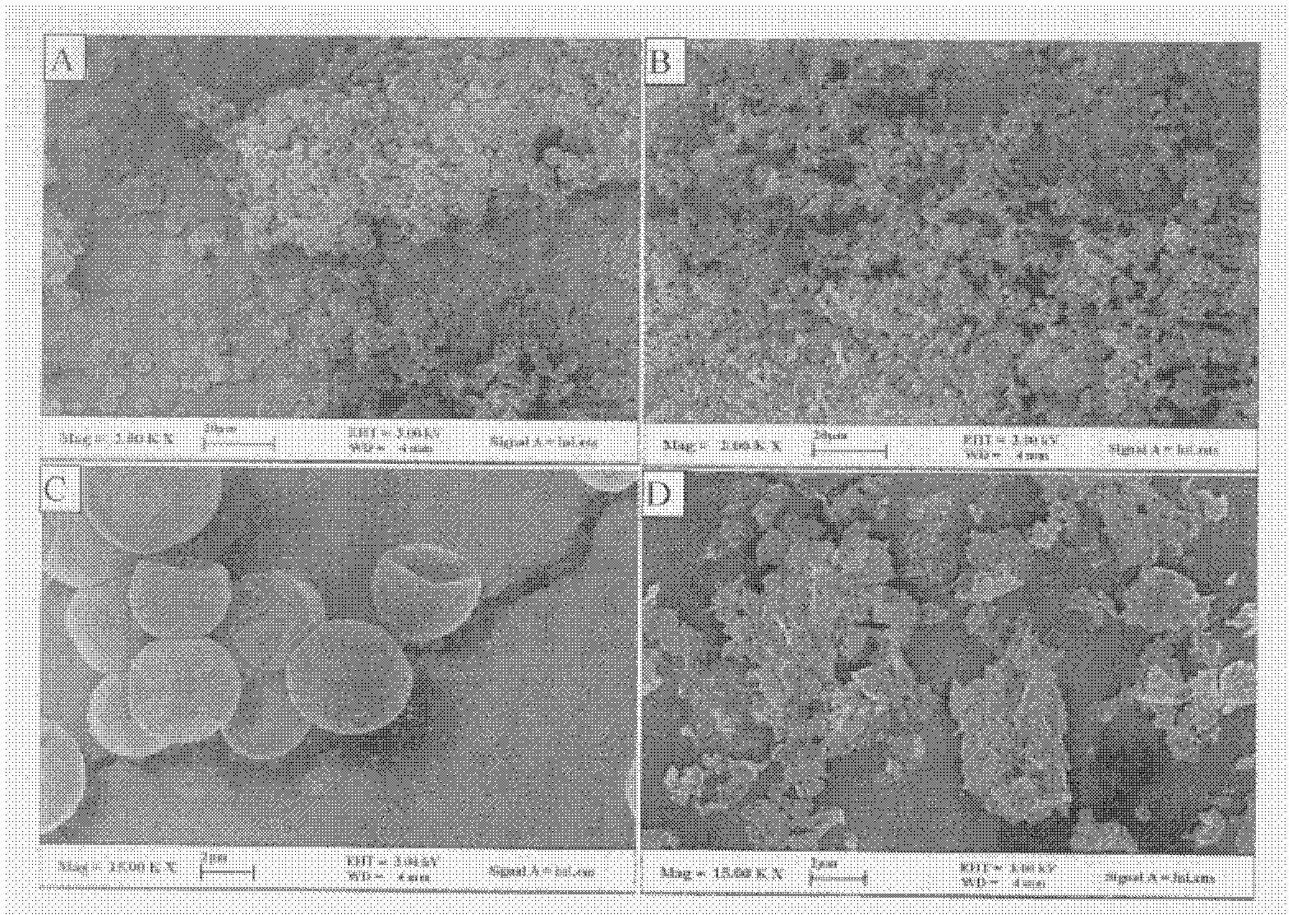

[0022] Heterotrophic chlorella was selected from C.protothecoides 0710 ("A method for producing biodiesel through high-density fermentation of heterotrophic chlorella CN101230364A" applied by Microalgae Bioenergy Laboratory, School of Life Sciences, Tsinghua University), through high-density heterotrophic Fermentation technology makes it rich in a large amount of neutral oils. Algae cell density higher than 50gl -1 The fermentation broth was centrifuged at 6000g for 4 minutes to fully precipitate the heterotrophic chlorella cells, removed the supernatant, added a small amount of water, oscillated to resuspend the cells, and then centrifuged at 6000g for 4 minutes to make the heterotrophic chlorella cells Fully precipitate, remove the supernatant, and repeat the above operation again to achieve the purpose of fully removing the culture medium and washing the algae cells. Take 30.00 g of wet algae and freeze-dry at -50° C. for 48 hours until constant weight to obtain 10.23 g of...

Embodiment 2

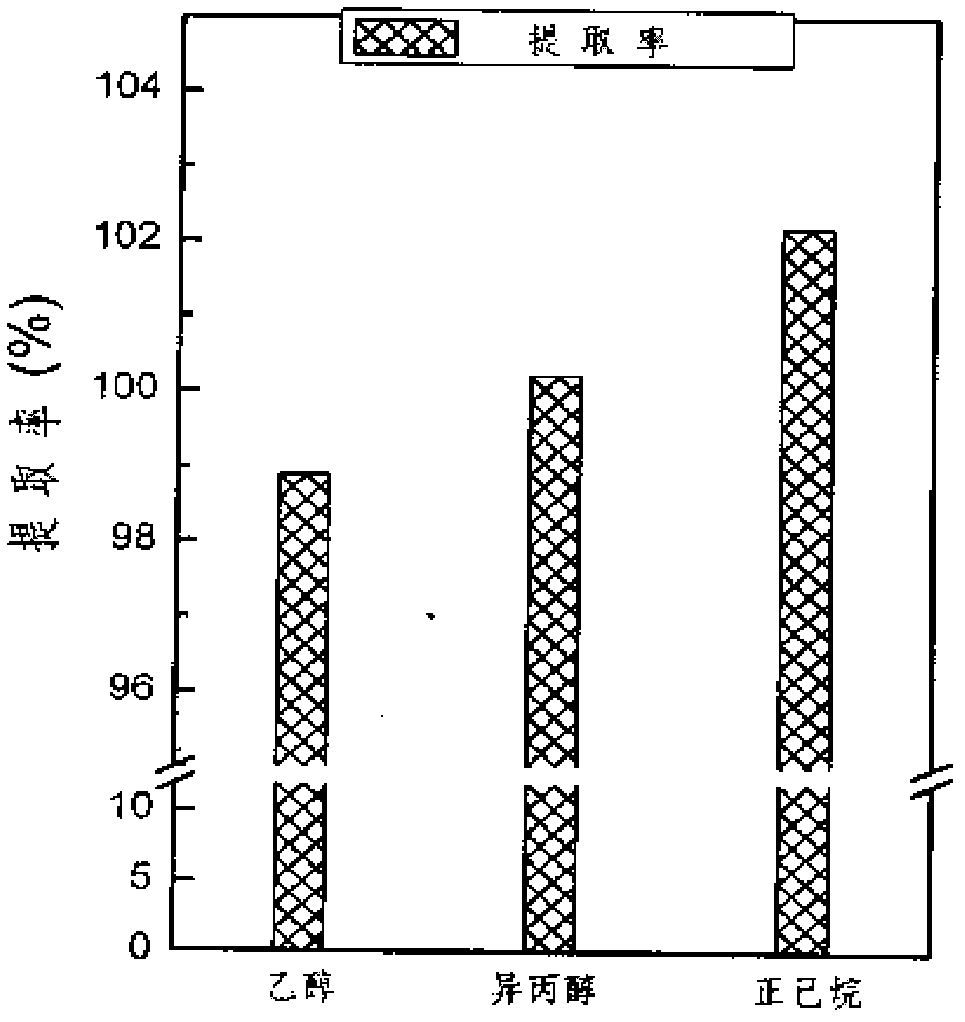

[0025] Freeze-dry the wet algae at -50° C. for 48 hours to constant weight to obtain dry algae powder (water content < 1 wt%). Ball milling of dry algae powder on a planetary ball mill: mix 30g of dry algae powder with 30ml of grinding solvent (ethanol, isopropanol or n-hexane), and then add 200g and 400g (diameter 5mm-10mm) of zirconia mill respectively The medium balls were put into a ball mill jar with a volume of 500ml, and after proper mixing, they were installed on a planetary ball mill for comparative experiments, and ball milled at 100rpm for 0.5, 1, 2, 4, and 6 hours respectively. Add 300ml of extraction solvent (chloroform, isopropanol or n-hexane) to the ball mill jar, filter and separate the mill balls with a filter screen with a pore size of 2mm, and obtain the algae debris / solvent mixture. Centrifuge the algae debris / grinding solvent mixture at 6000g for 4 minutes, retain the upper liquid, and distill under reduced pressure at 65°C until the solvent is completely...

Embodiment 3

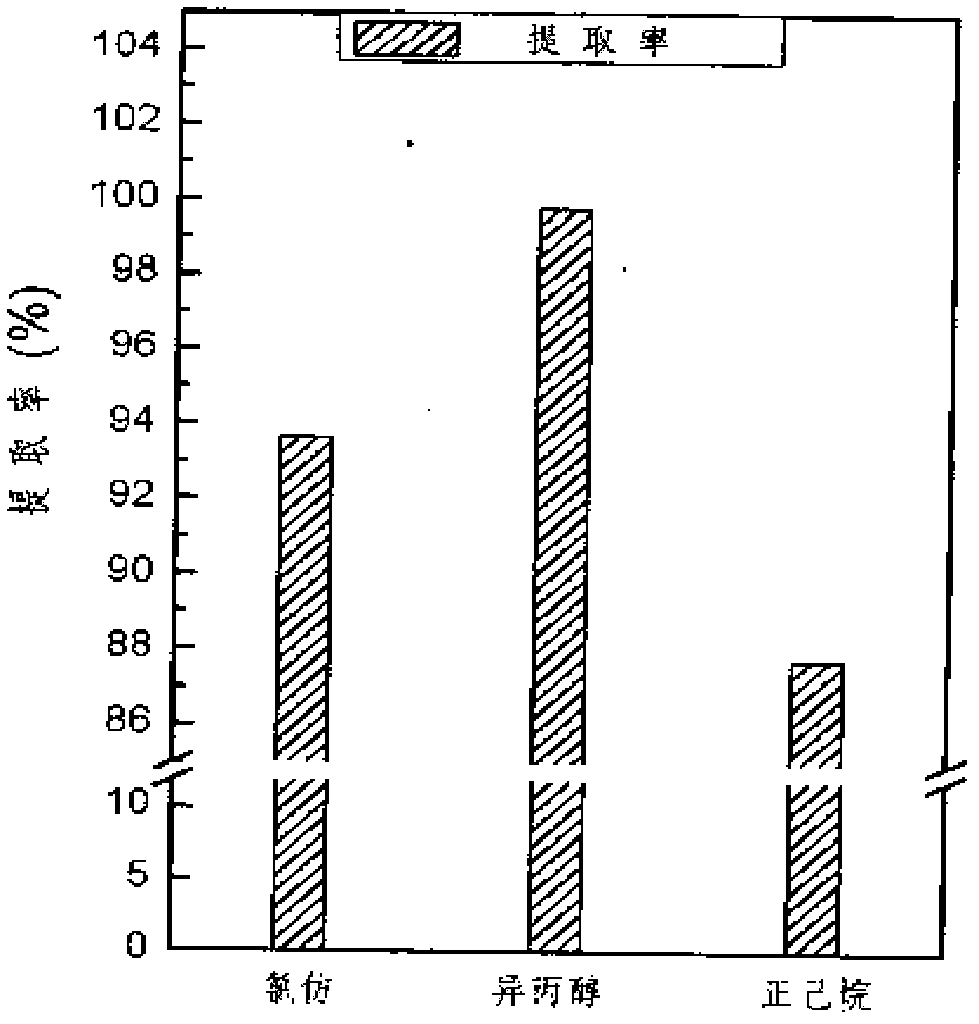

[0027] For wet algae without drying treatment, ball milling optimization is as follows: 30g of wet algae (water content is 61.9 ± 3.1wt%) is mixed with 30ml of grinding solvent (ethanol, isopropanol or n-hexane), and then 200g, 400g (Diameter 5mm-10mm) into a ball milling jar with a volume of 500ml, after mixing properly, install it on a planetary ball mill for comparative experiments, and ball mill at 100rpm for 6, 12, and 24 hours respectively. Add 300ml of extraction solvent (chloroform, isopropanol or n-hexane) to the ball mill jar, filter and separate the mill balls with a filter screen with a pore size of 2mm, and obtain the algae debris / solvent mixture. The mixture was subjected to ultrasonic crushing under the following conditions: power 600W, frequency 20KHz, working time 3 seconds, interval time 3 seconds, total time 40 minutes. Subsequently, the algae debris / grinding solvent mixture was centrifuged at 6000 g for 4 minutes, the upper solvent was retained, and the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com