Treatment method for heat exchanger fouling during biodiesel production process, and preparation method for biodiesel

A technology of biodiesel and a treatment method, which is applied in the field of biodiesel preparation, can solve the problems of fouling and blockage of heat exchangers, increase the operation cycle of heat exchangers, etc., and achieve the effects of high cost efficiency and increase of operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a kind of preparation method of biodiesel, the method comprises the following steps:

[0026] (1) under transesterification reaction conditions, oil and methanol are contacted to obtain the crude biodiesel product;

[0027] (2) distilling the crude biodiesel product under the condition that methanol is distilled out to obtain methanol and the crude biodiesel product through distillation;

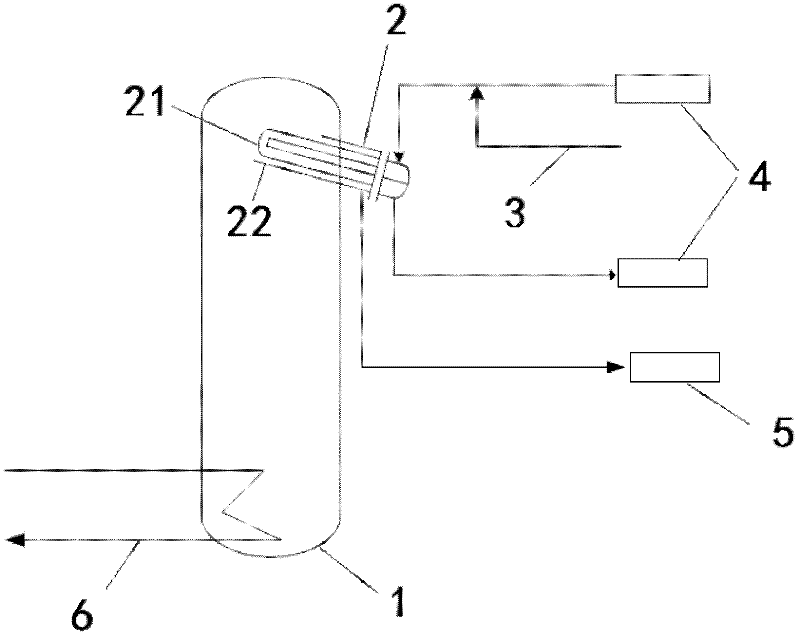

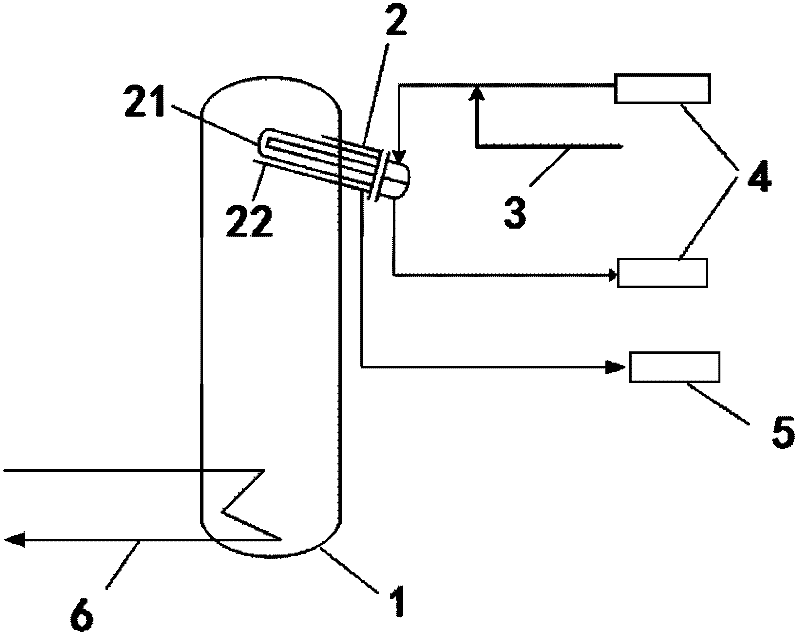

[0028] (3) After the distilled biodiesel crude product is washed with water and light components are removed, it is sent to the flash tower with a heat exchanger on the upper part for flash evaporation, and the component steam of biodiesel passes through the flash tower After the heat exchanger inside is cooled, it is discharged from the upper part of the flash tower into the biodiesel collection tank, and the heavy components with a boiling point higher than the biodiesel are extracted from the bottom of the flash tower;

[0029] (4) When the heat...

Embodiment approach

[0046] According to the preparation method of biodiesel of the present invention, wherein, a kind of preferred embodiment comprises the following steps:

[0047] 1) Under transesterification reaction conditions, the oil and methanol are contacted to obtain a crude biodiesel product, and the crude biodiesel product is distilled in a methanol distillation tower to remove most of the methanol to obtain a crude biodiesel product through distillation ;

[0048] 2) washing the distilled biodiesel crude product in a water washing tower, removing most of the glycerin and other low-carbon alcohols with water, and obtaining the washed biodiesel crude product;

[0049] 3) Distilling the washed biodiesel crude product in a light component distiller to remove light components whose boiling point is lower than the boiling point of biodiesel;

[0050] 4) Send the crude biodiesel product after removing the light components with a boiling point lower than the boiling point of biodiesel into a...

Embodiment 1

[0058] In the high-pressure reactor, oil ester and methanol are added at a molar ratio of 9:1, and the crude biodiesel product is obtained after reacting at 260°C and 6.5MPa for 2 hours; the obtained crude biodiesel product is distilled in a methanol distillation tower , the distillation conditions include: pressure 20kPa, tower top temperature 64°C, tower bottom temperature 86°C to obtain the crude biodiesel product through distillation; wash the crude biodiesel product through distillation and the washing water with the above-mentioned temperature of 90°C from the water respectively The bottom and top of the tower are continuously sent to the above-mentioned water washing tower for countercurrent contact, wherein 0.25 volume of desalted water is used for washing relative to 1 volume of biodiesel crude product. The washing conditions include: washing temperature 90 ° C, pressure 0.2 MPa, biological The contact time between the crude diesel product and the washing water is 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com