High plasticity superhigh temperature niobium-based directionally solidified alloy and preparation method thereof

An ultra-high temperature, high plasticity technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as low toughness, low density, and limited applications, and achieve wide heat treatment window, good plasticity, and good process performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

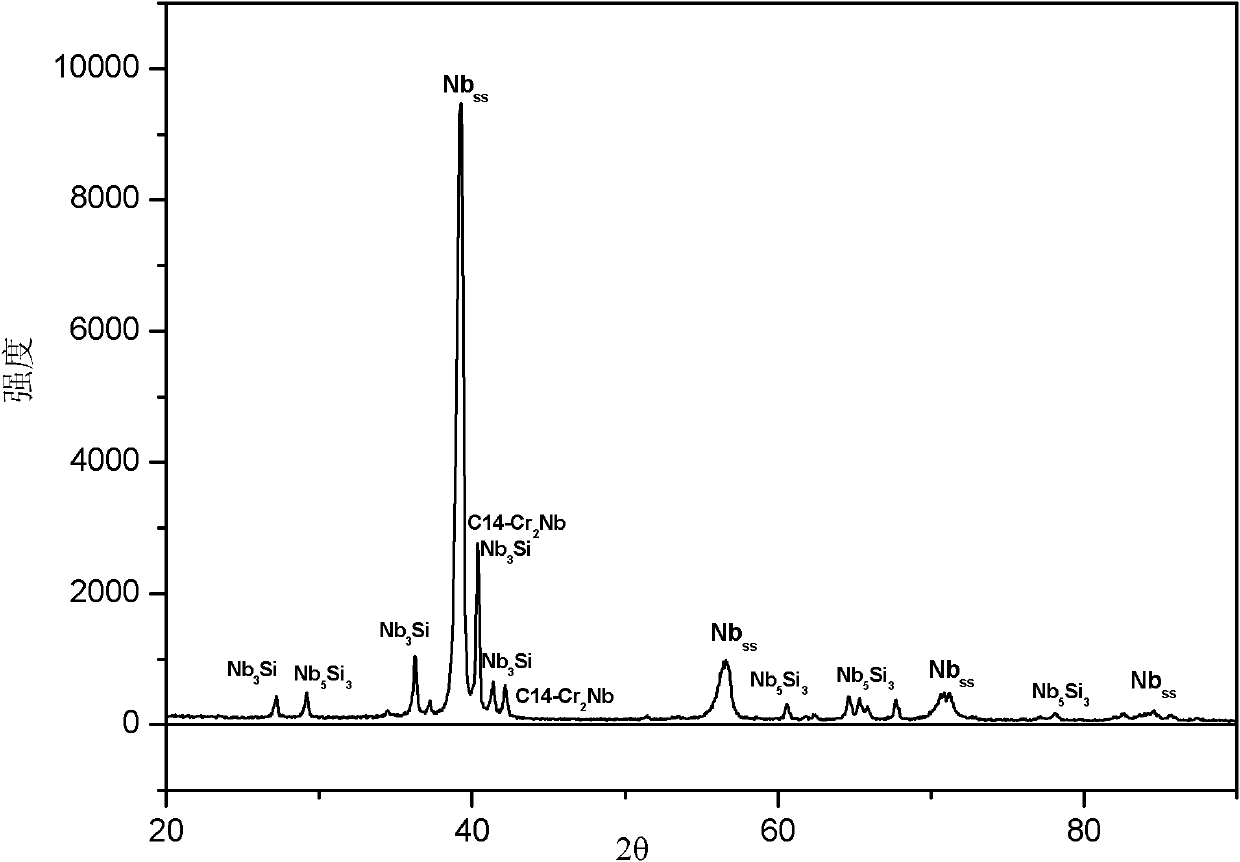

[0038] In this example, the vacuum non-consumable melting master alloy is used, and the composition is shown in Table 3-5; the temperature gradient range of the directional solidification furnace is 40K / cm, the pouring temperature is 1600°C, the mold shell temperature is consistent with the pouring temperature, and the drawing rate is Super high temperature alloy test rods were prepared in the range of 8mm / min. The phase composition of the alloy as-cast sample is as follows: figure 1 Table 6 shows the microhardness values of each phase of as-cast matrix and strengthening phase.

[0039] Table 3 (wt%)

[0040] C

B

Al

f

Ti

Si

Cr

Ta

Nb

0.015

0.05

5.0

2.2

26

4.6

6.0

2.5

Remain

[0041] Table 4 residual elements (wt%)

[0042] the element

Cu

Fe

mn

Zr

Ni

W

O

N

S

P

content

0.08

0.42

0.1...

Embodiment 2

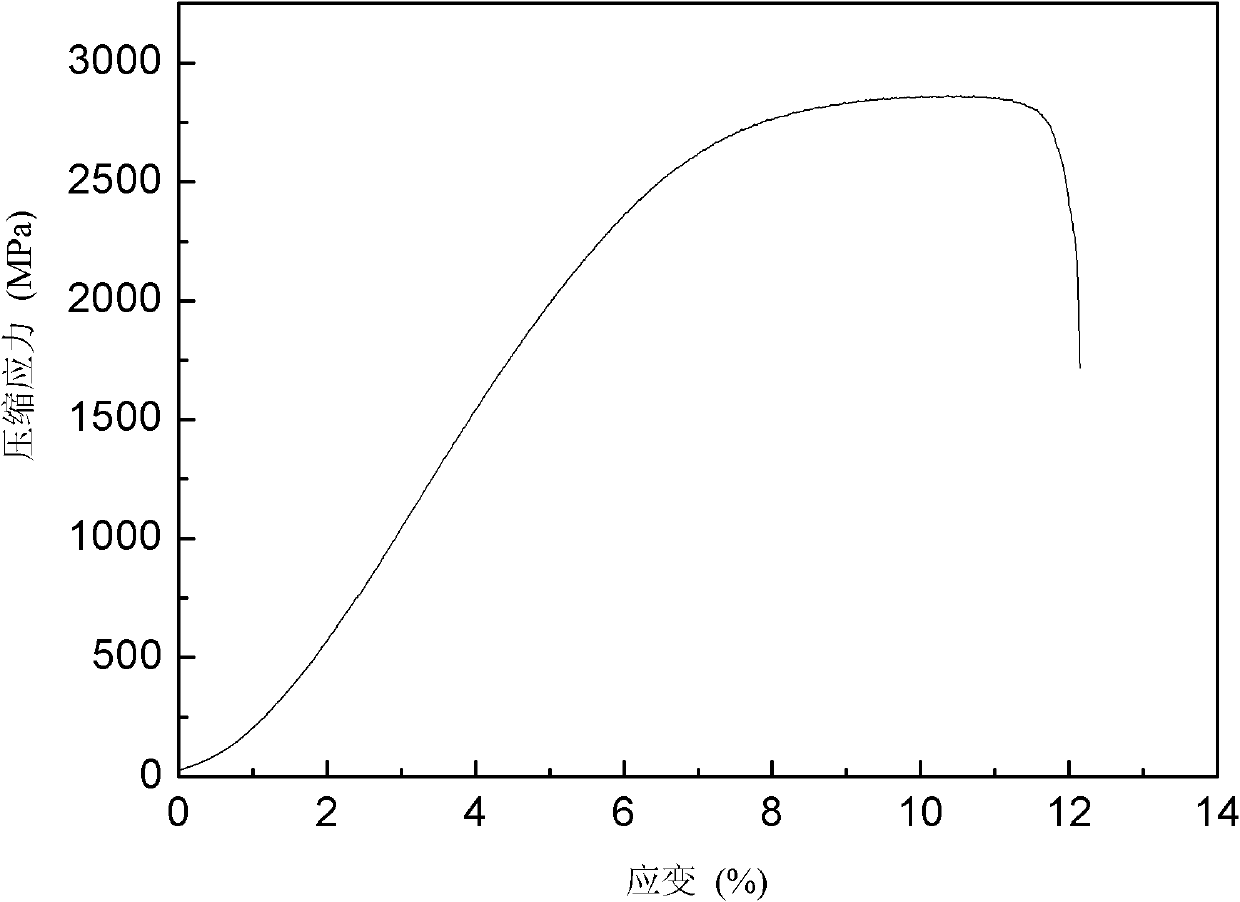

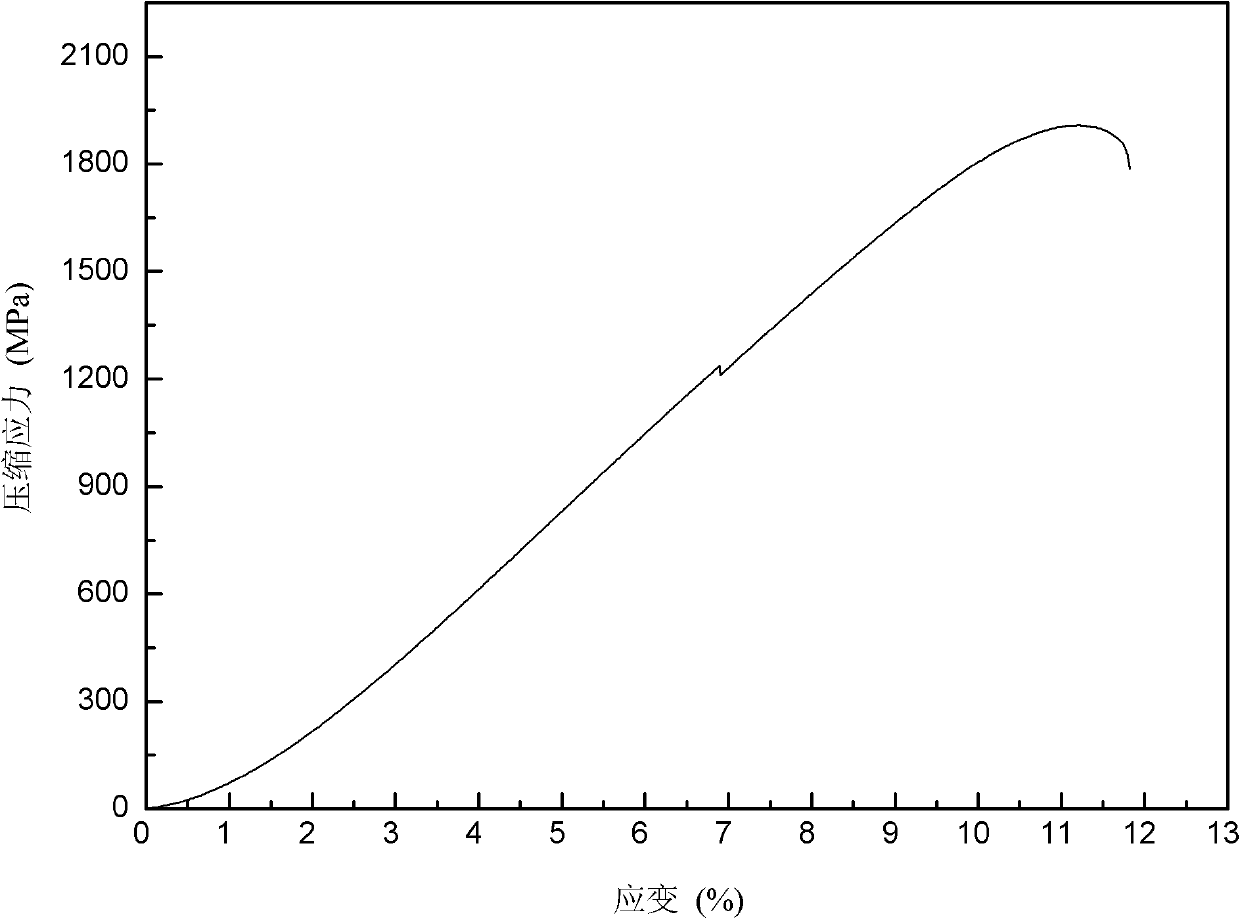

[0049] The master alloy is melted in a vacuum non-consumable melting furnace, and its composition is shown in Table 7-9. The samples of niobium-based directional alloy were prepared by HRS method in ZGG-0.02 directional solidification furnace. The temperature gradient range of the directional solidification furnace is 60K / cm, the pouring temperature is 1650°C, the shell temperature is consistent with the pouring temperature, and the pulling rate of the directional solidification single crystal growth is 4mm / min. The mechanical properties of the directional solidification test bar are tested in the cast state, and the compression performance curve is as follows: figure 2 and image 3 shown.

[0050] Table 7 (wt%)

[0051] C

[0052] Table 8 residual elements (wt%)

[0053] the element

[0054] Table 9 Trace elements (ppm)

[0055] the element

[0056] It can be seen from the figure that the alloy has a high compressive strength in the as-ca...

Embodiment 3

[0058] The master alloy is smelted in a vacuum non-consumable melting furnace, and its composition is shown in Table 10-12. The samples of niobium-based directional alloys were prepared by ultra-high temperature and high-speed directional solidification in a directional solidification furnace. The temperature gradient range of the directional solidification furnace is 80K / cm, the pouring temperature is 1700°C, the shell temperature is consistent with the pouring temperature, and the directional drawing rate is 6mm / min. The mechanical properties of the directional solidification test bar are tested in the cast state, and the compression performance curve is as follows: Figure 4 and Figure 5 shown.

[0059] Table 10 (wt%)

[0060] C

[0061] Table 11 Residual elements (wt%)

[0062] the element

[0063] Table 12 Trace elements (ppm)

[0064] the element

[0065] Depend on Figure 4 It can be seen that at 800°C, the alloy still has high str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com