Low-alloy seamless steel pipe for supporting crane cantilever

A technology of seamless steel pipe and crane, applied in the field of seamless steel pipe manufacturing, can solve the problems of high price and unguaranteed delivery time, and achieve the effects of improving quality, easy welding and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation process of the low-alloy seamless steel pipe used for crane cantilever support is described in conjunction with the examples.

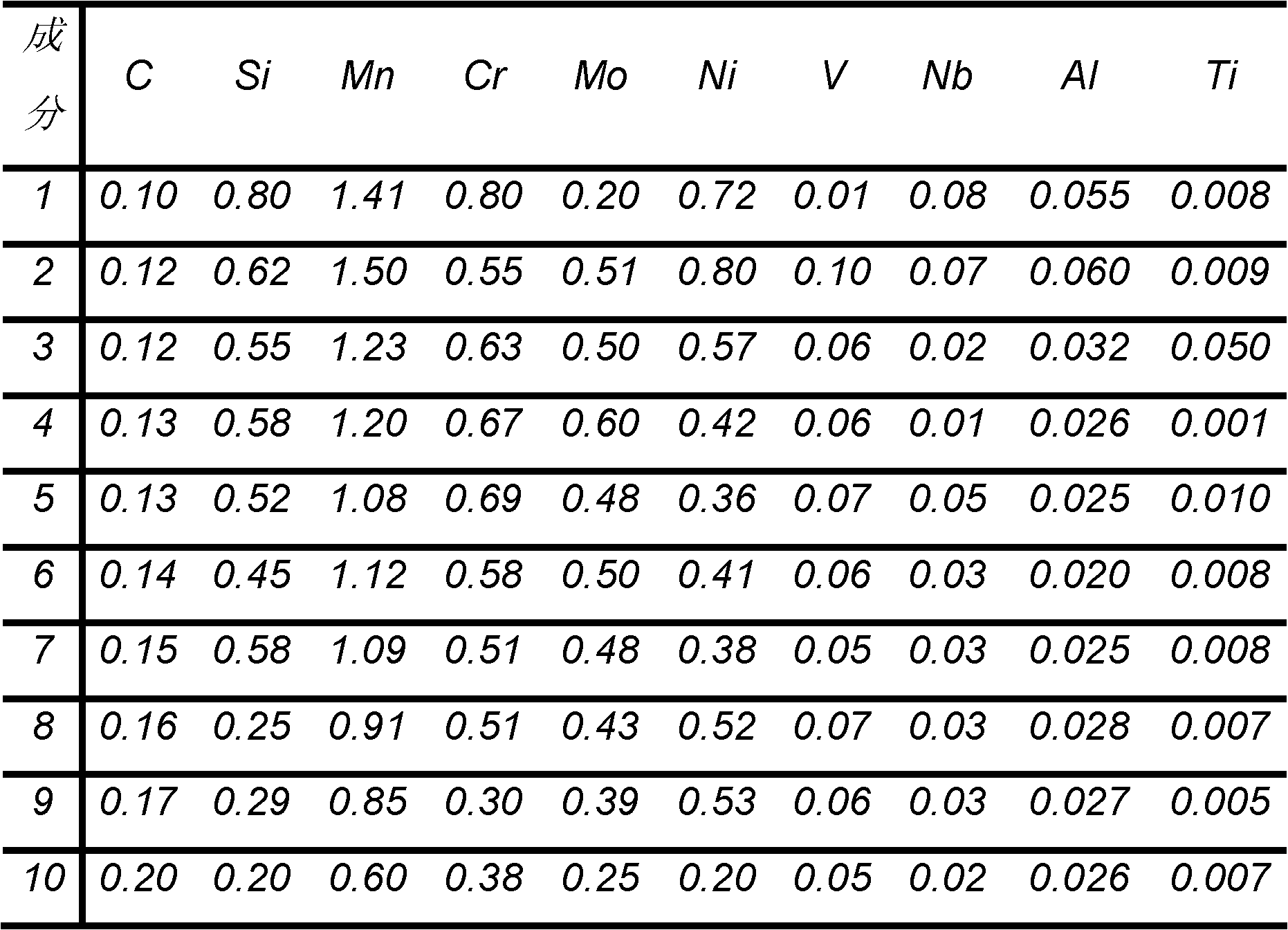

[0016] The low-alloy seamless steel pipe for crane cantilever support of the present invention, the composition design range of the seamless steel pipe is by weight %: C: 0.10-0.20%, Si: 0.2-0.8%, Mn: 0.6-1.5%, Cr: 0.3 -0.8%, Mo: 0.2-0.6%, Ti: 0.001-0.050%, Al: 0.02-0.06%, Ni: 0.2-0.8%, V: 0.01-0.10%, Nb: 0.01-0.08%, and the rest is Fe The metallographic structure of the seamless steel pipe after quenching and tempering treatment is tempered sorbite, and the carbon equivalent is controlled to be Ceq≤0.55;

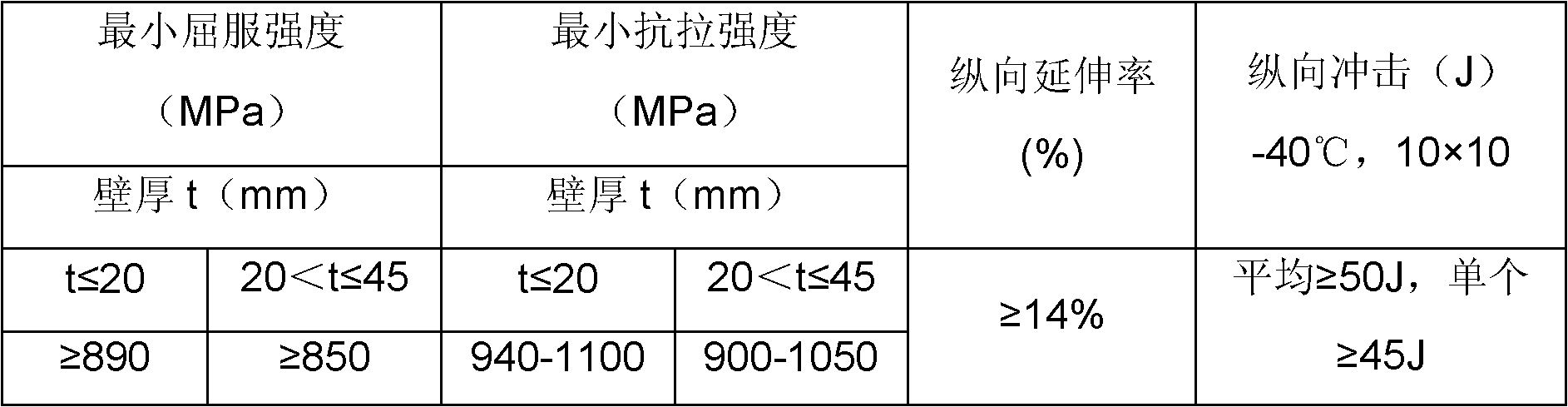

[0017] The mechanical properties of seamless steel pipes produced according to the above range are:

[0018]

[0019] Take the seamless steel pipe of TP890C specification as an example. At present, the main chemical composition of such products used in the market is based on 20 steel, adding appropriate alloying elemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com