Independently adjustable continuous variable valve timing and lift mechanism

A valve timing, adjustable technology, used in mechanical equipment, engine components, machines/engines, etc., to solve problems such as inability to independently adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An exemplary embodiment will be described below with reference to the drawings.

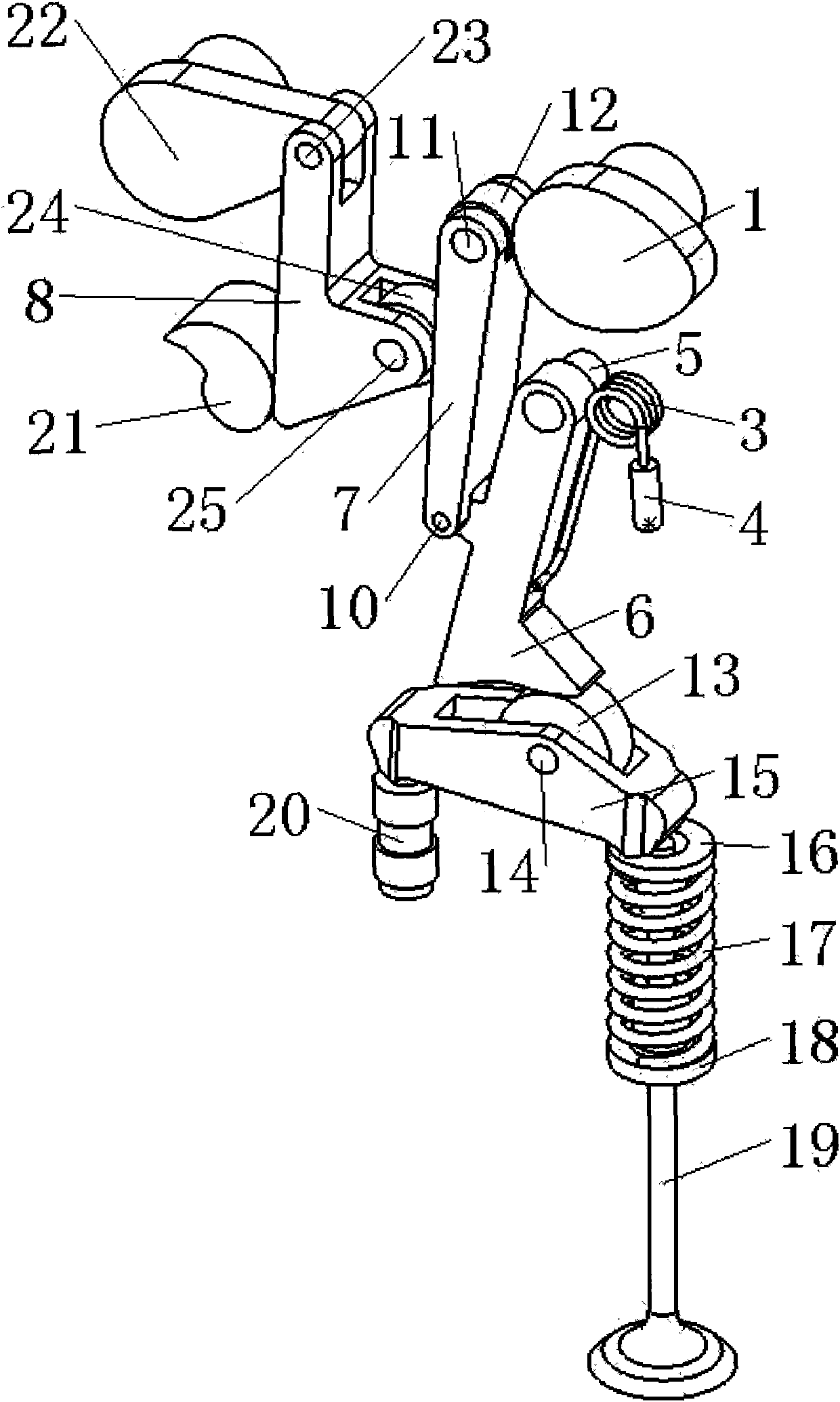

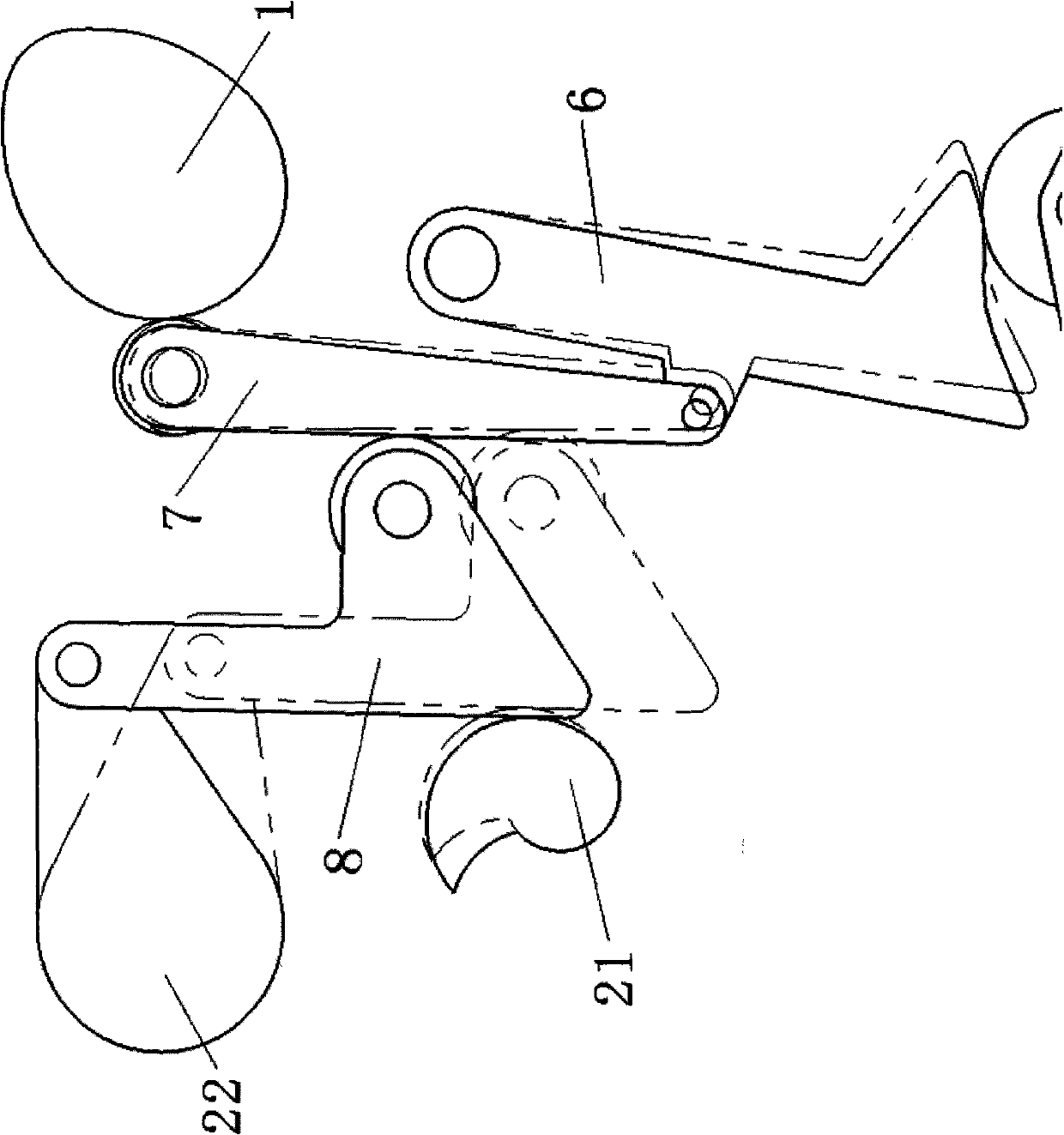

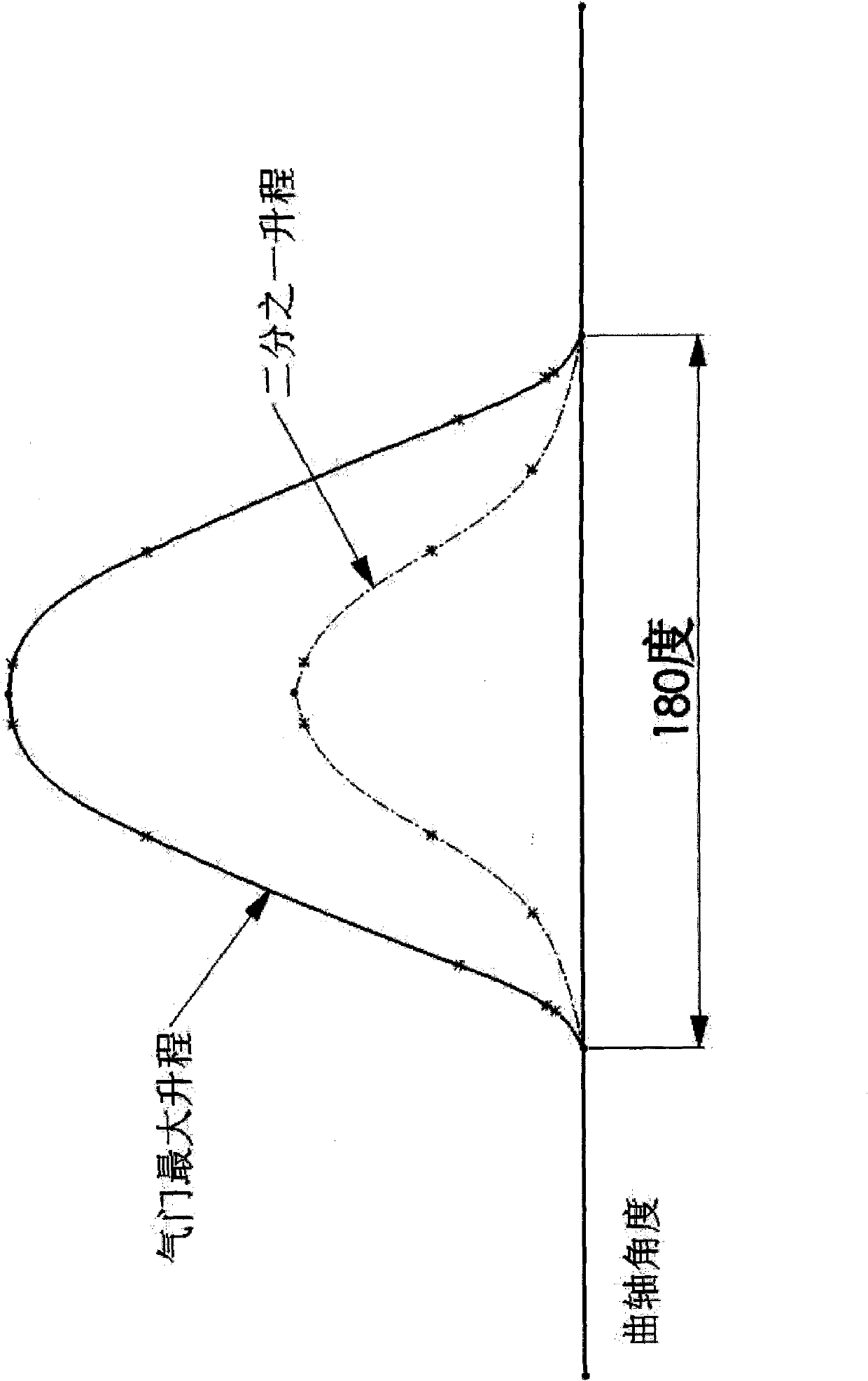

[0015] figure 1 It is a schematic diagram showing the position and connection relationship between the parts of the mechanism. One end of the variable speed pendulum 7 has a roller 12 and a shaft 11, the roller 12 is in close contact with the cam 1 and is pushed by the cam 1; the other end is connected with the boss of the variable speed pendulum 2 through the shaft 10. One end of the variable speed pendulum 6 is fixed on the cylinder head through the rotating shaft 5, and can rotate according to the rotating shaft 5. Roller 24 is arranged on fulcrum rod 8, and roller 24 contacts with the side of variable speed pendulum 7, becomes the support point of swing of variable speed pendulum 7; Turn and pull up and down. One side of the fulcrum rod 8 is pressed by the eccentric shaft 21 , so that the fulcrum rod 8 can support the lateral pressure of the shift pendulum 7 . The end face of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com