Vortex gas steam turbine

A gas steam and vortex technology, which is applied to gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of low efficiency and heat transfer rate and rate of gas turbines, reduced effective enthalpy of gas turbines, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

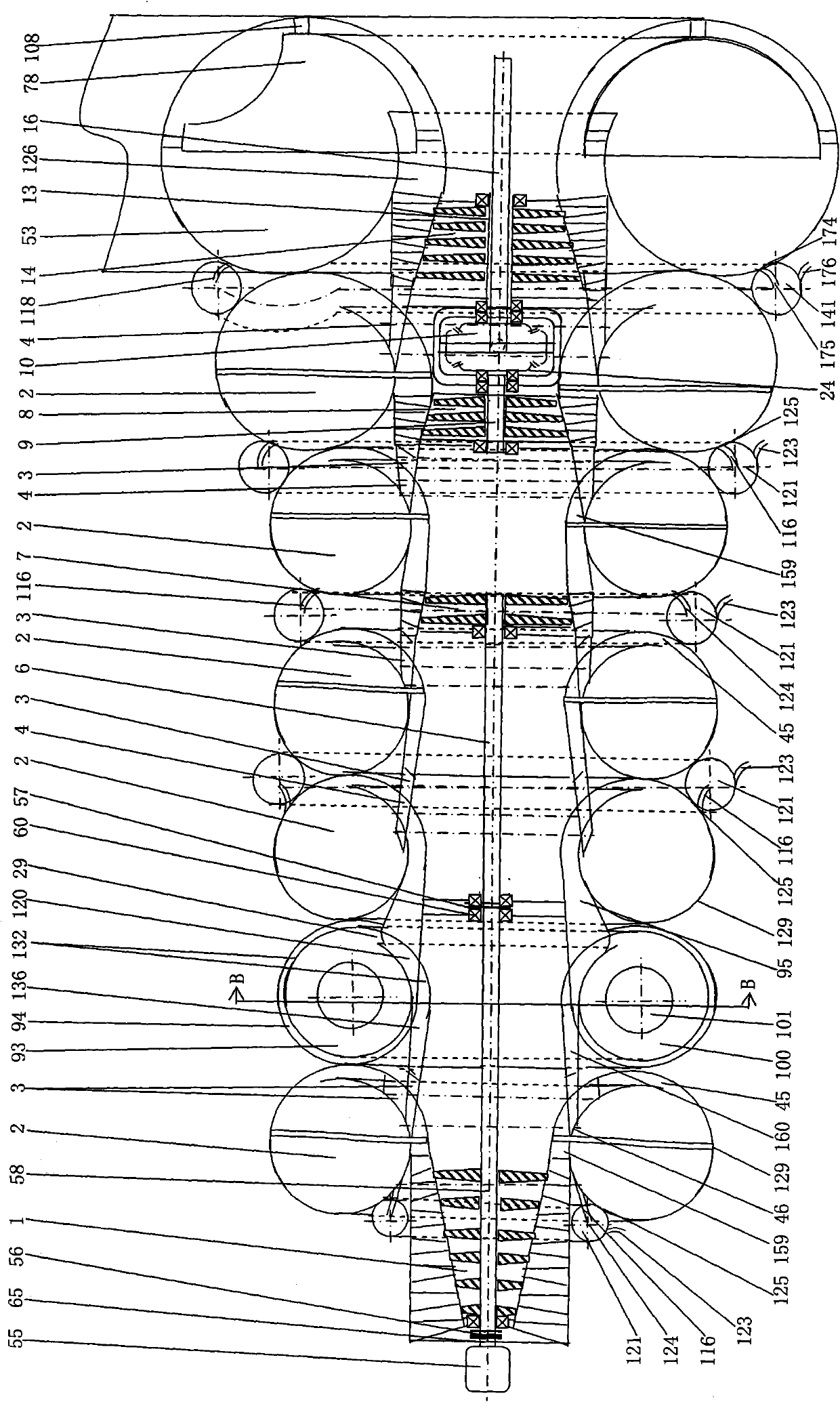

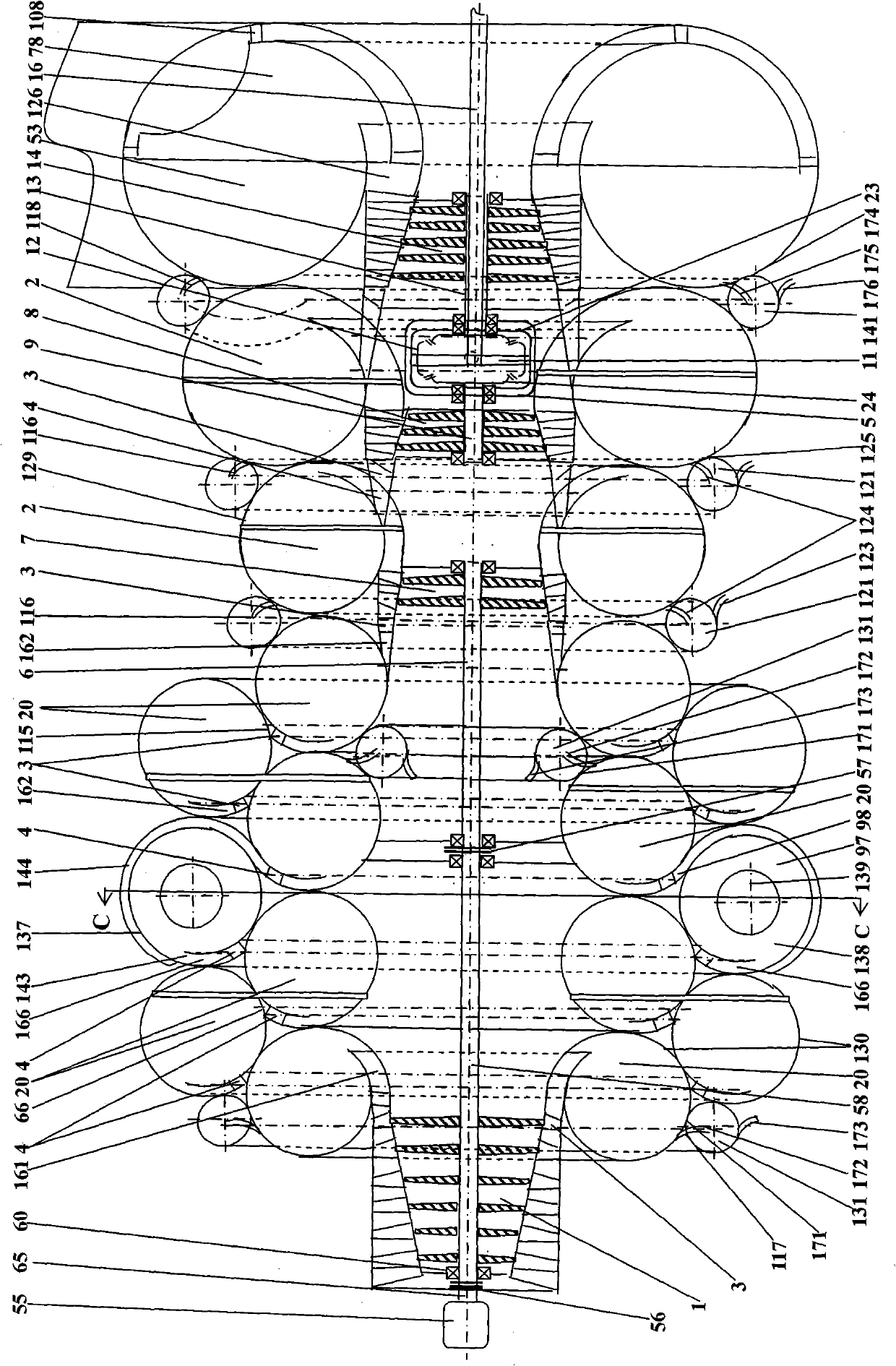

[0015] Specific implementation mode one: combine Figure 1 to Figure 17 To illustrate this embodiment, the scroll gas steam turbine includes a starter 55, a starter clutch 56, a compressor 1, a combustion chamber, a ratchet type overrunning clutch 57, a sleeve type differential coupling 10, a high pressure turbine 7, Medium pressure turbine 8 and low pressure turbine 14; it is characterized in that: described scroll gas steam turbine also comprises scroll supercharger, scroll exhaust device 53, solid-liquid separation device, wedge control device; The turbocharger consists of a first group of series-connected multi-stage scroll superchargers arranged between the compressor 1 and the combustion chamber and a second group of series-connected multi-stage scroll superchargers arranged between the combustion chamber and the high-pressure turbine 7 , the third set of series-connected multi-stage scroll turbochargers set between the high-pressure turbine 7 and the medium-pressure tur...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination Figure 1 ~ Figure 4 with Figure 11 Describe this embodiment, the wedge-shaped regulating device of present embodiment is the displacement type wedge-shaped regulating device 3, the displacement-type wedge-shaped regulating device 3 is made up of the displacement-changing wedge-shaped regulating device runner 31, two connecting rods 33, multiple A displaceable wedge body 30, at least two sets of position variable wedge body regulating device slideways 32, at least two gear shafts 19, at least four gears 39 and at least four tooth racks 34, are composed; the gears 39 and the racks 34 are two The number of those is the same, two adjacent racks 34 are arranged in parallel, and are fixed on the corresponding two connecting rods 33 respectively, and two gears 39 are correspondingly fixed on each gear shaft 19, and each rack 34 and An adjacent gear 39 meshes, and the gear shaft 19 and the gear 39 are rotatable parts. A plurality...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 1 ~ Figure 4 , Figure 12 with Figure 13 Describe this embodiment, the deformable wedge regulating device 4 of the present embodiment is composed of the deformable wedge regulating device flow channel 110, a plurality of rollers 36, a plurality of deformable wedges 37, and multiple sets of deformable wedge regulating device slideways 77. A plurality of adjustment shafts 38 and a plurality of adjustment wheels 35; multiple sets of slides 77 of the deformation wedge adjustment device are installed on the corresponding parallel walls of the flow channel 110 of the deformation wedge adjustment device. Type wedge regulating device slideways 77 are arranged in parallel; each deformable wedge 37 is made up of two elastic steel plates, and the two ends of the two elastic steel plates are affixed to each other, and one end of each deformable wedge 37 is fixed on the deformable On the corresponding two walls of the wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com