Plate type heat exchanger with pulsating heat pipes

A pulsating heat pipe and heat exchanger technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of fluid pressure loss, reduced heat transfer efficiency, reduced heat transfer efficiency, etc. The effect of resistance, high heat exchange efficiency and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

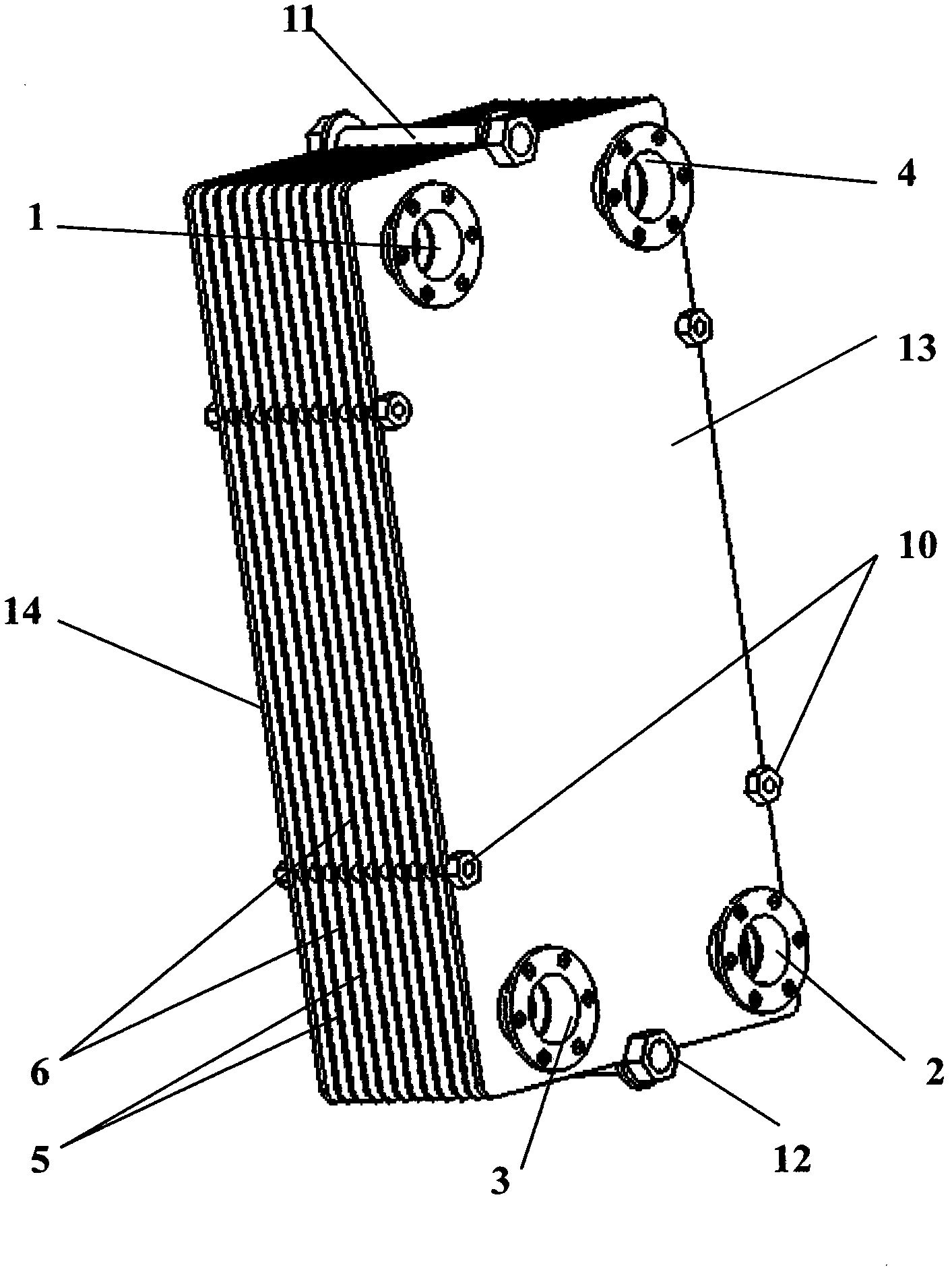

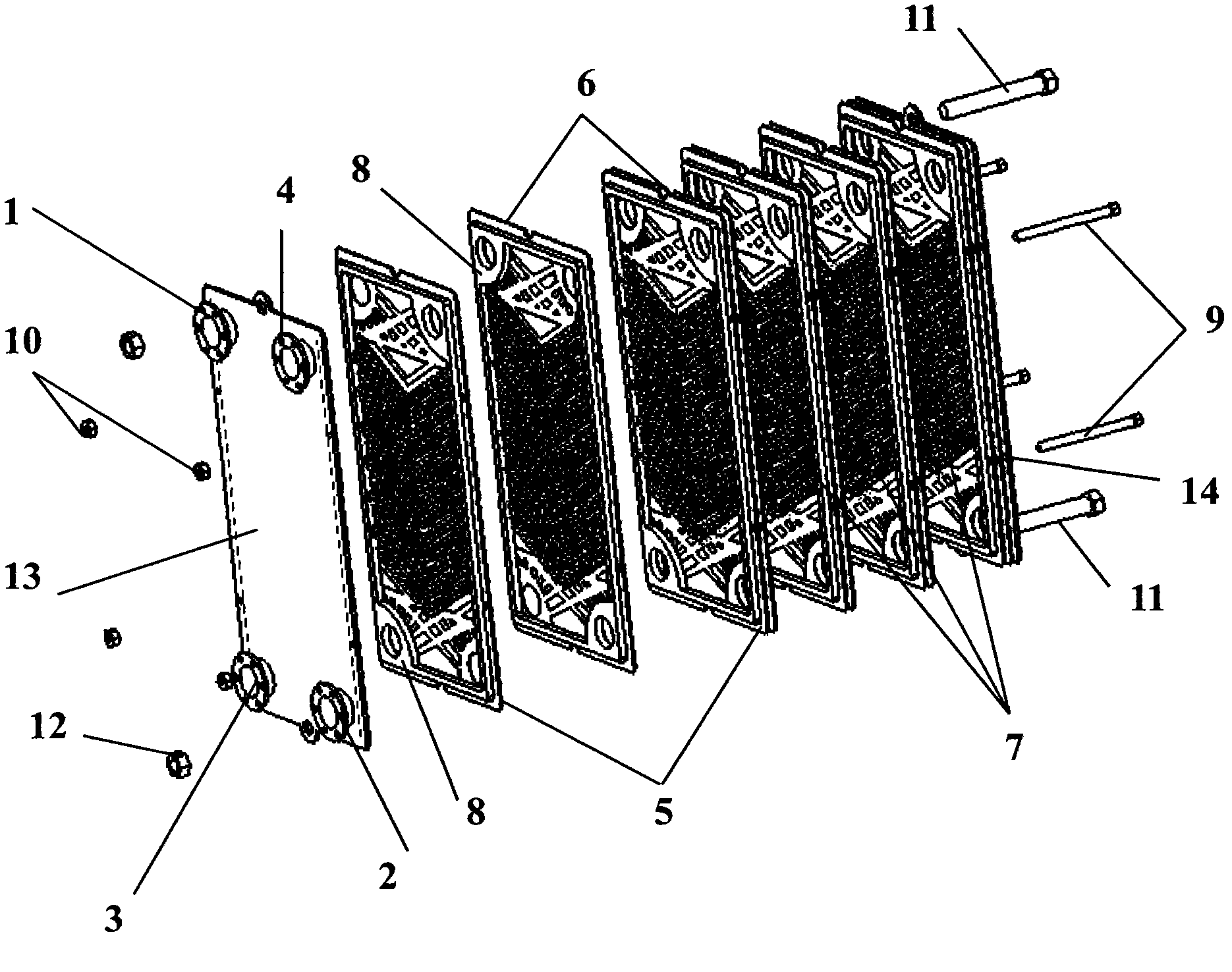

[0027] Such as Figure 1-Figure 7 Specific embodiments of the present invention are shown.

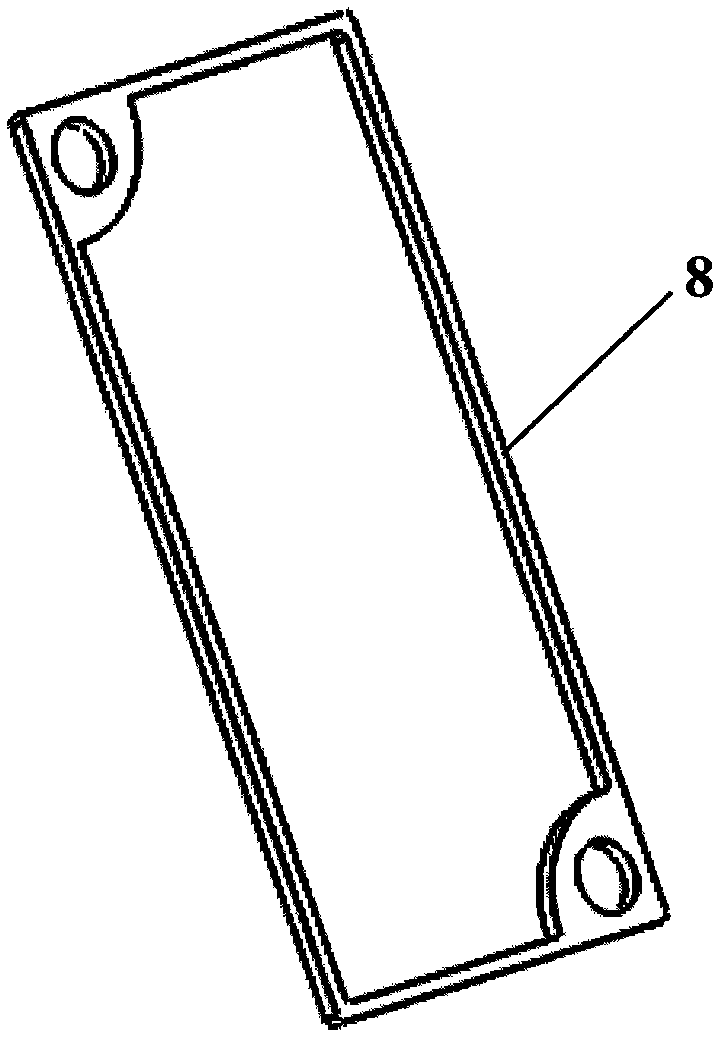

[0028] Such as Figure 1-Figure 7 As shown, the pulsating heat pipe includes a hot fluid inlet 1, a hot fluid outlet 2, a cold fluid inlet 3, a cold fluid outlet 4, a heat exchange fin A5, a heat exchange fin B6, a pulsation heat pipe 7, a sealing ring 8, a small through bolt 9, Nut 10, large through bolt 11, nut 12, front cover plate 13, rear cover plate 14.

[0029] In specific implementation, Figure 6 The shown multiple groups of pulsating heat pipes 7 repeatedly traverse Figure 4 Heat exchanger fin A5 shown as well as Figure 5 As shown in the heat exchange sheet B6, the arranged pulsating heat pipe 7 needs to be filled with liquid under vacuum conditions on a special liquid filling table (not shown in the figure), and the liquid filling rate can be between 30% and 70% according to the specific conditions. The working conditions can be selected, and the working medium can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com