Determination method of sodium oxide content in regenerated sand of sodium silicate sand

A technology for regenerating sand and glass sand, which is applied in the direction of analyzing materials through chemical reactions and observing the impact on chemical indicators. It can solve the problems of affecting the judgment of titration end points, large errors in sodium oxide content, and inability to oxidize. Solve problems such as sodium dissolution, and achieve a reasonable and scientific detection scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

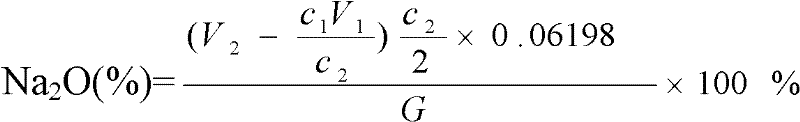

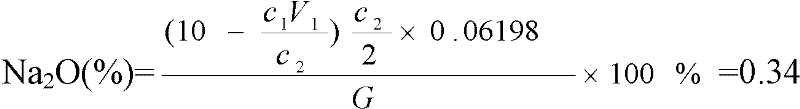

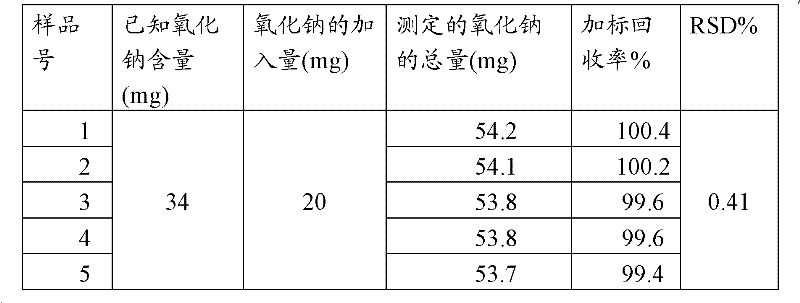

[0029] One, use method of the present invention to measure sodium oxide content in the regenerated sand of sodium silicate sand, described regenerated sand is to use sodium silicate as the molding sand of binding agent for the old sand that casting produces and obtains through regeneration treatment, according to Based on empirical or preliminary measurements, it is known that the content of sodium oxide in reclaimed sand is below 1%. Take out 6 equal portions, and measure one of them according to the following steps:

[0030] 1) Use a magnet to remove the iron filings mixed in the reclaimed sand;

[0031] 2) Place the 10g reclaimed sand in a beaker with the quality of iron filings removed, add water and 10ml of sulfuric acid standard solution with a concentration of 0.5872mol / L, heat and stir on a magnetic stirrer; control the stirring during the heating and stirring process The speed gradually increases from low to high, and at the same time prevents the liquid from splashi...

Embodiment 2

[0045] One, use method of the present invention to measure sodium oxide content in the regenerated sand of sodium silicate sand, described regenerated sand is to use sodium silicate as the molding sand of binding agent for the old sand that casting produces and obtains through regeneration treatment, according to Based on experience or preliminary measurement, it is known that the content of sodium oxide in reclaimed sand is below 1%, take out 6 equal parts, and measure one part according to the following steps:

[0046] 1) Use a magnet to remove the iron filings mixed in the reclaimed sand;

[0047] 2) Place the 10g reclaimed sand in a beaker with the quality of iron filings removed, add water and 10ml of sulfuric acid standard solution with a concentration of 0.5024mol / L, and heat and stir on a magnetic stirrer; control the stirring during the heating and stirring process The speed gradually increases from low to high, and at the same time prevents the liquid from splashing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com