Lithography device and method for measuring multi-light spot zero offset

A lithography equipment and zero-position deviation technology, which is applied in the field of integrated circuit equipment manufacturing to achieve the effect of avoiding the zero-position deviation of the light spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

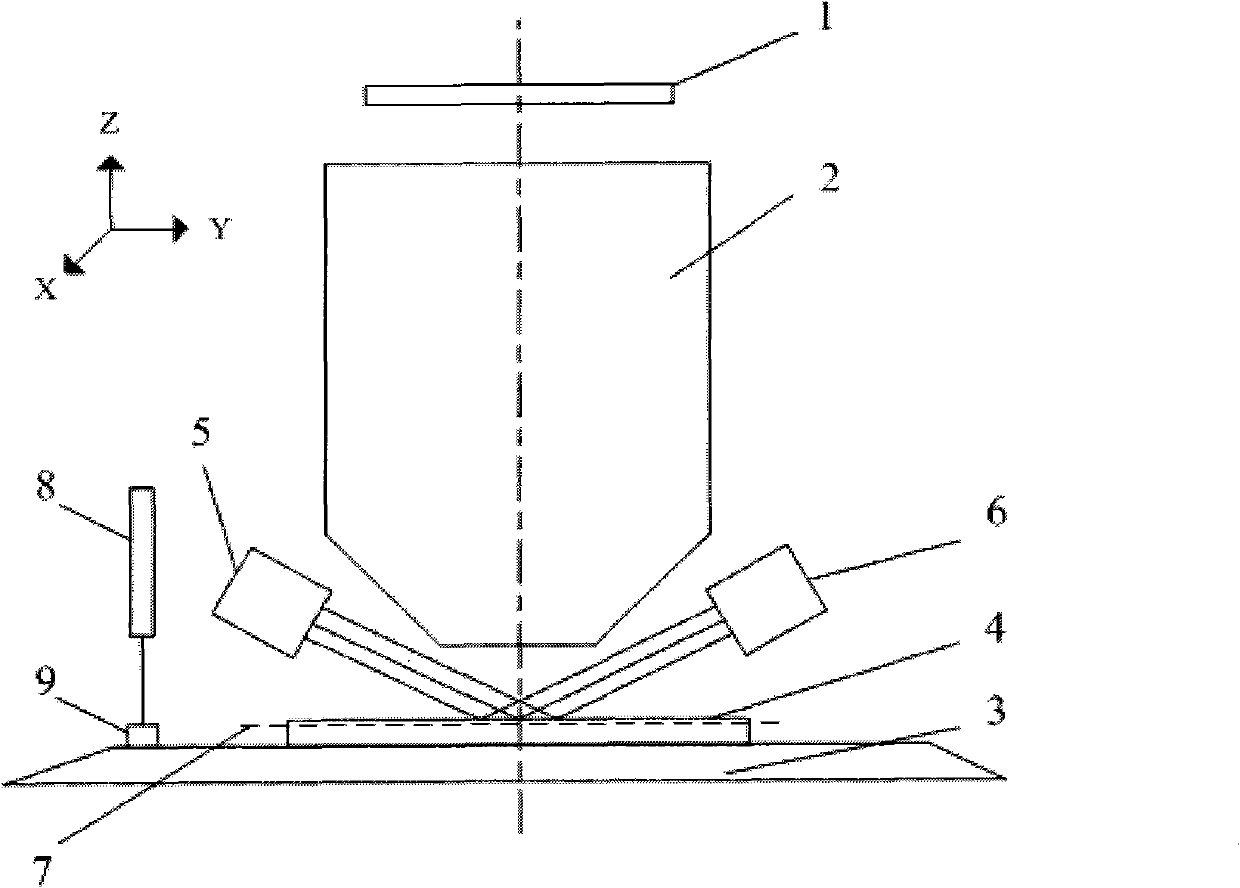

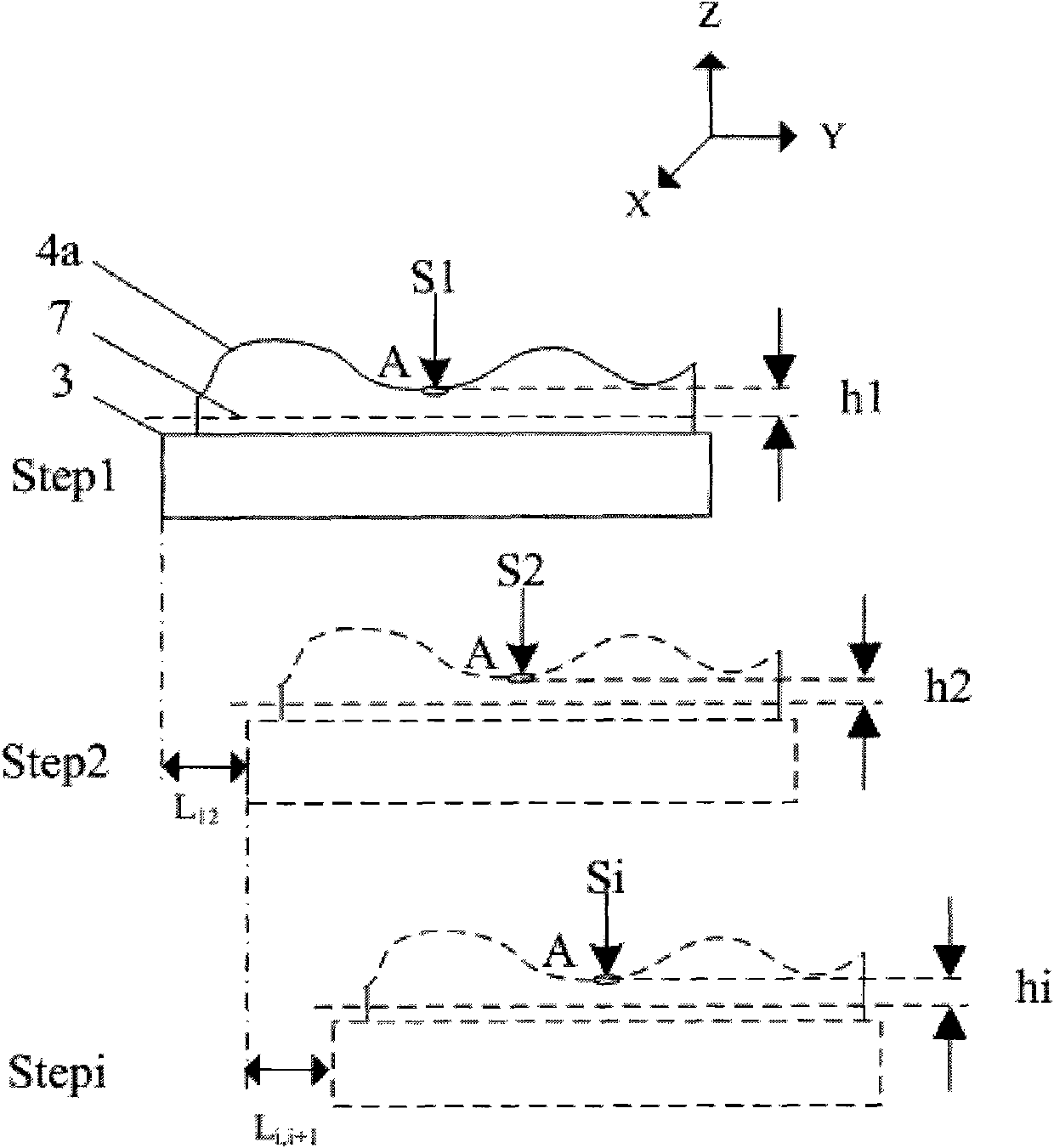

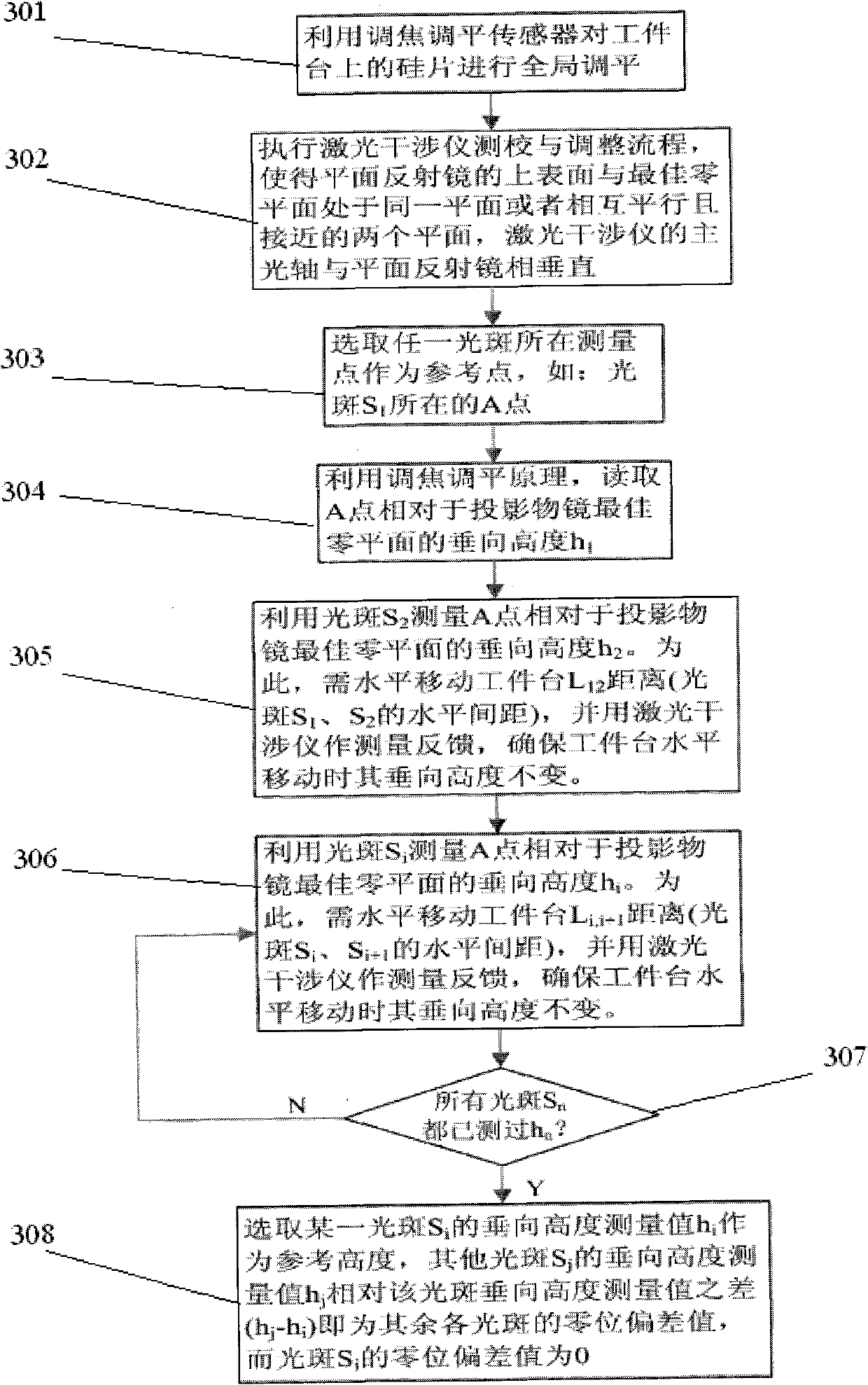

[0023] The object of the present invention is to provide a lithographic equipment capable of measuring the zero position deviation of multiple spots. The lithographic equipment includes: a light source for providing an exposure light beam. The light source can be a mercury lamp, a laser light source, or other high-brightness light sources, etc. . The projection system is used to project the graphics on the mask onto the substrate, and the projection system can be a total refraction type, reflective type, or catadioptric projection objective lens; the workpiece stage system is used to move the substrate and other A system on a lithographic apparatus that can provide at least 3 degrees of freedom of motion. The focusing and leveling system is used to measure the vertical position and inclination angle of the substrate. The substrate may be a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com