Method for implementing dual-switch grid-control TWT (Traveling Wave Tube) modulator with high pulse repetition frequency and low power consumption on basis of MOS (Metal Oxide Semiconductor) tube

A technology of MOS tubes and implementation methods, which is applied in the field of electric vacuum tube grid-controlled modulators, can solve the problems of complex peripheral circuits of switching tubes, and achieve the effects of low power consumption, simplified circuits, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

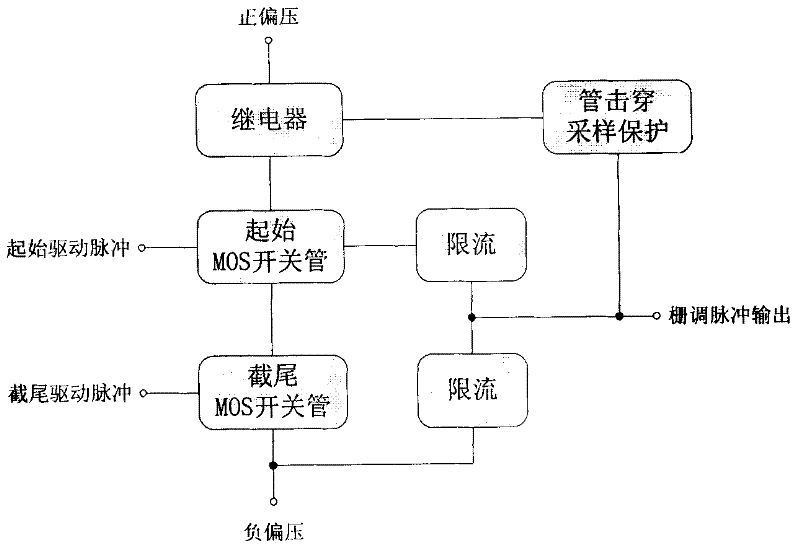

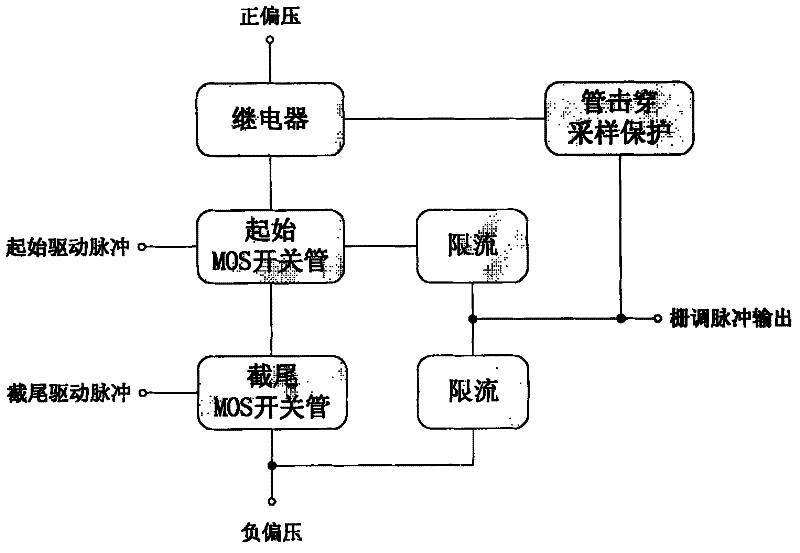

Method used

Image

Examples

Embodiment Construction

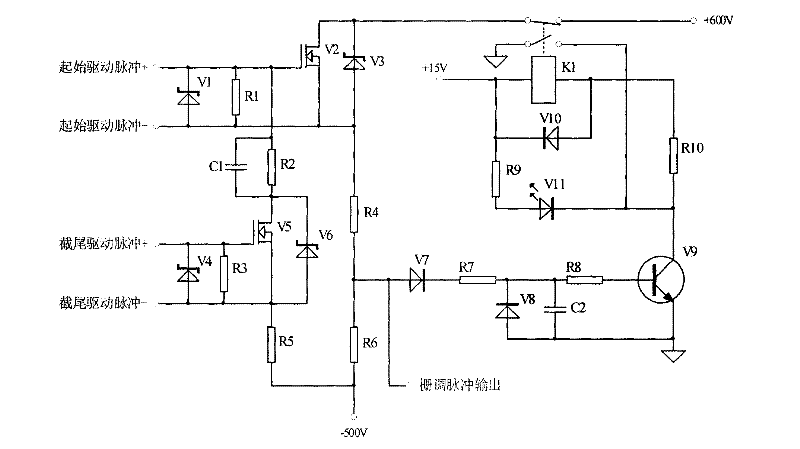

[0010] see figure 2 , the initial drive pulse drives the MOS transistor V2 to conduct, and the positive bias voltage of 600V is applied to the gate of the traveling wave tube through V2, K1, and R4. Resistor R4 is a positive bias current limiting resistor, and the value of R4 should not be large, otherwise it will affect the leading edge characteristics of the grid modulation pulse. The type of V2 is IXBH16N170, a MOS tube with a withstand voltage of 1700V; V3 is a transient suppression diode with a value of 1200V, which acts as an overvoltage protection for V2.

[0011] The truncated drive pulse drives the MOS transistor V5 to turn on, pulls the gate voltage of V2 to a low level forcibly, and turns off V2. At this time, the negative bias voltage of 500V rapidly charges the capacitance in the grid interspace of the traveling wave tube to the negative bias value through the conduction loop of V5. Resistor R5 acts as a current limiter, and choosing appropriate values of C1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com